Combined-type gas distributor and fluidized bed reactor

A gas distributor and gas distribution technology, which is applied in the fields of organic chemistry, hydrocarbons, hydrocarbons, etc., can solve the problems of low catalyst utilization efficiency, easy nozzle blockage, easy gas deviation, etc., and achieve high catalyst utilization efficiency and gas Uniform distribution and easy fluidization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1 A combined gas distributor and melamine fluidized bed reactor

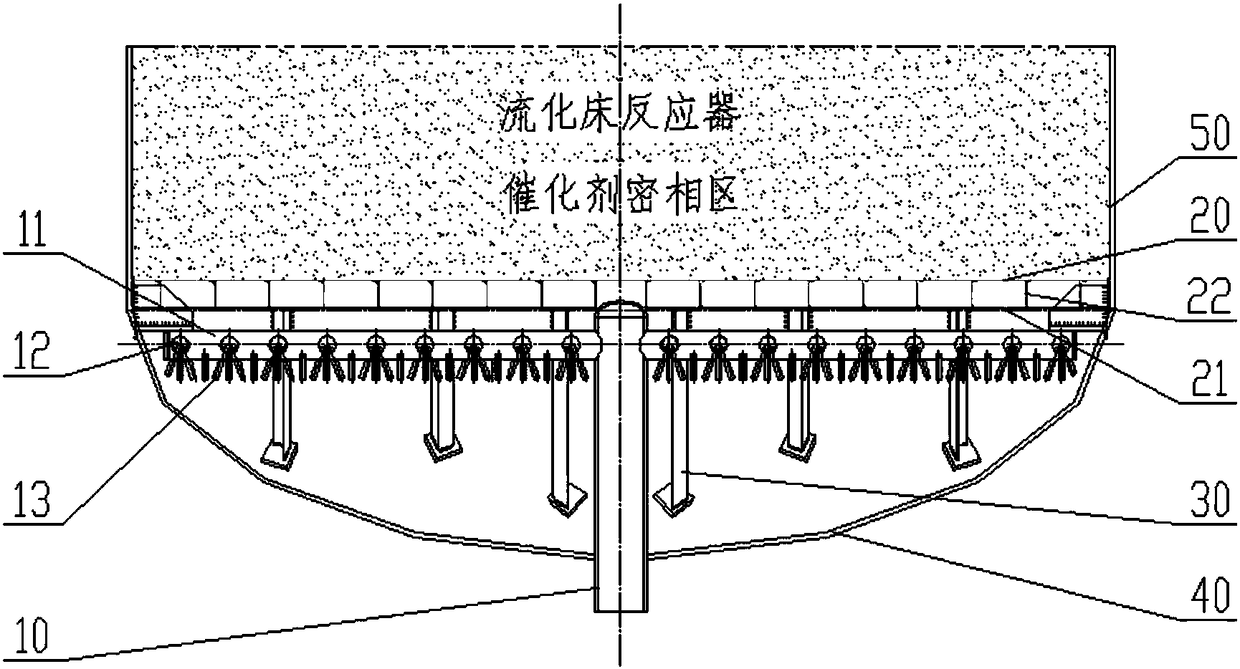

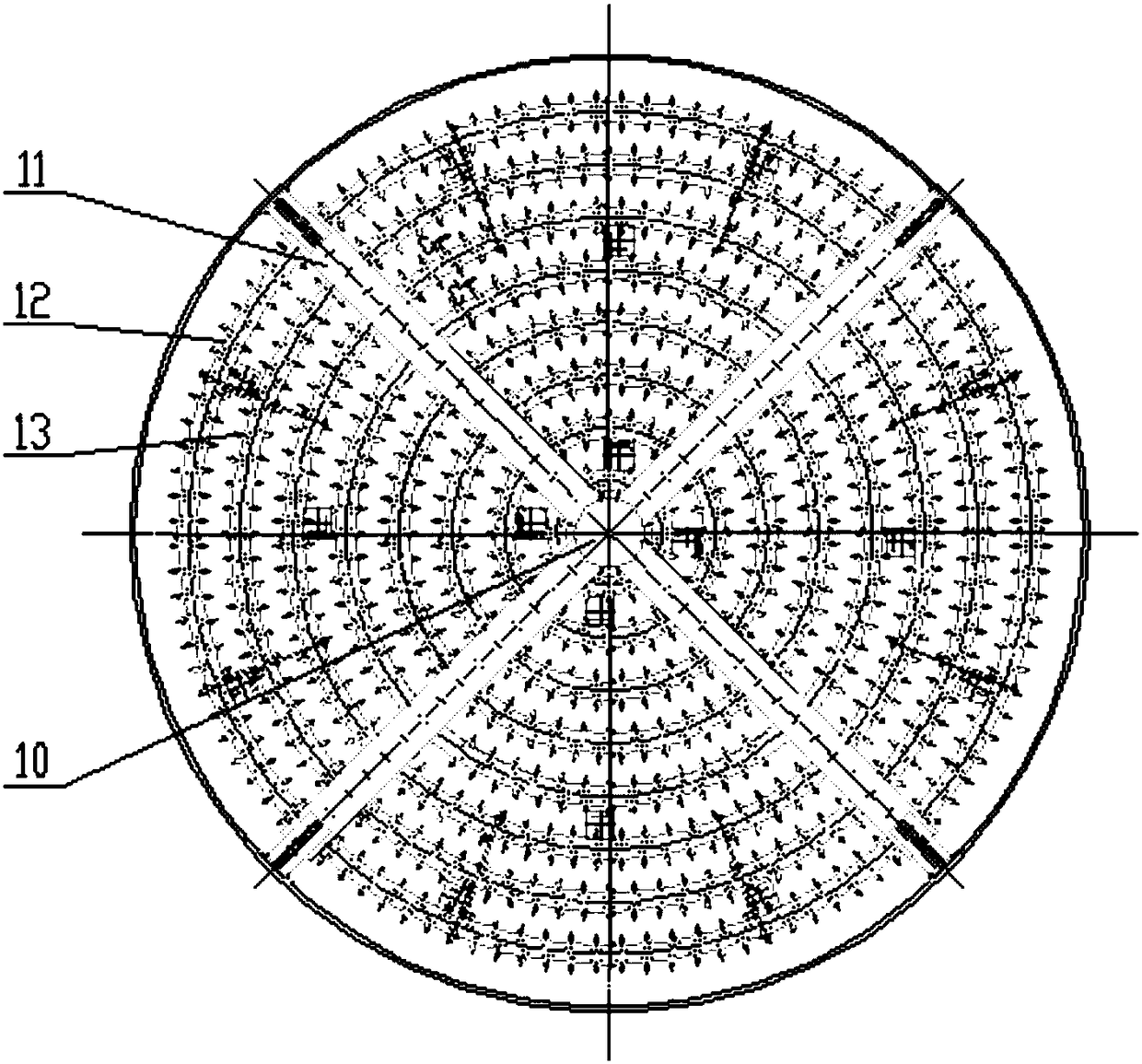

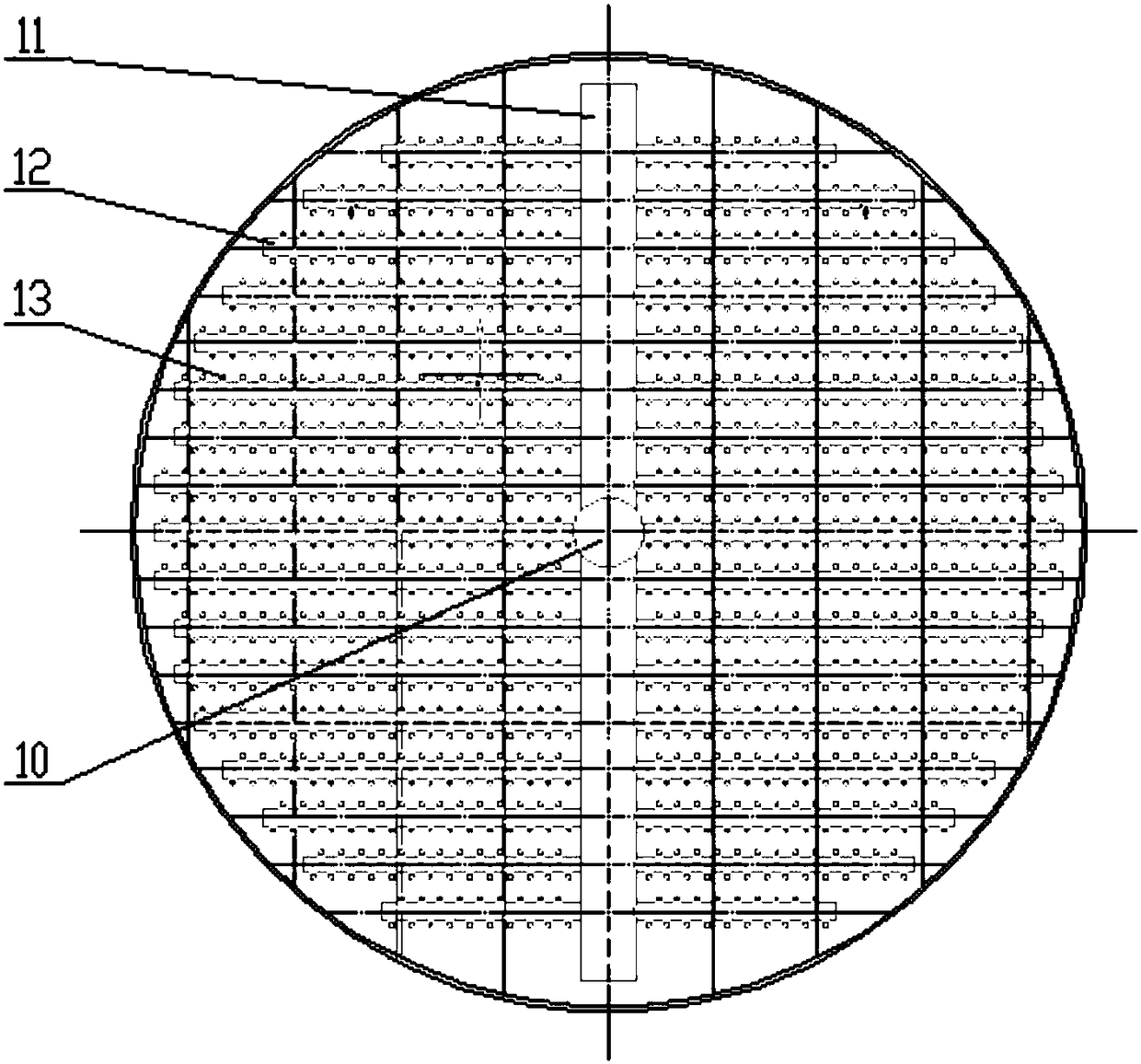

[0059] A combined gas distributor, such as figure 1 As shown, it includes a primary gas distributor and a secondary gas distributor; the primary gas distributor includes a gas distribution main pipe 11, a gas distribution branch pipe 12 and a nozzle 13 that are basically arranged on the same plane, and the gas distribution main pipe 11 is connected with a gas distribution branch pipe 12. The nozzles 13 are evenly arranged on the gas distribution main pipe 11 and the gas distribution branch pipe 12; the secondary gas distributor includes a lower perforated plate 21 and an upper perforated plate 20 arranged in sequence from bottom to top, and each plate has interlaced holes; the secondary gas distributor is arranged above the primary gas distributor.

[0060] The primary gas distributor communicates with the gas inlet pipe 10 through a pipeline.

[0061] The gas distribution main pipe 11 communica...

Embodiment 2

[0078] Example 2 A combined gas distributor and methanation fluidized bed reactor

[0079] A combined gas distributor, such as figure 1 As shown, it includes a primary gas distributor and a secondary gas distributor; the primary gas distributor includes a gas distribution main pipe 11, a gas distribution branch pipe 12 and a nozzle 13 that are basically arranged on the same plane, and the gas distribution main pipe 11 is connected with a gas distribution branch pipe 12. The nozzles 13 are evenly arranged on the gas distribution main pipe 11 and the gas distribution branch pipe 12; the secondary gas distributor includes a lower perforated plate 21 and an upper perforated plate 20 arranged in sequence from bottom to top, and each plate has interlaced holes; the secondary gas distributor is arranged above the primary gas distributor.

[0080] The primary gas distributor communicates with the gas inlet pipe 10 through a pipeline.

[0081] The gas distribution main pipe 11 commun...

Embodiment 3

[0099] Example 3 A combined gas distributor and methanol to olefins fluidized bed reactor

[0100] A combined gas distributor, such as figure 1 As shown, it includes a primary gas distributor and a secondary gas distributor; the primary gas distributor includes a gas distribution main pipe 11, a gas distribution branch pipe 12 and a nozzle 13 that are basically arranged on the same plane, and the gas distribution main pipe 11 is connected with a gas distribution branch pipe 12. The nozzles 13 are evenly arranged on the gas distribution main pipe 11 and the gas distribution branch pipe 12; the secondary gas distributor includes a lower perforated plate 21 and an upper perforated plate 20 arranged in sequence from bottom to top, and each plate has interlaced holes; the secondary gas distributor is arranged above the primary gas distributor.

[0101] The primary gas distributor communicates with the gas inlet pipe 10 through a pipeline.

[0102] The gas distribution main pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com