Ball cage holder broaching clamp

A cage and cage seat technology, which is applied to broaching machines, broaching machines, manufacturing tools, etc., can solve the problems of difficulty in ensuring accurate rotation angles, substandard products, and inconvenient placement of ball cage cages, so as to avoid uncertainty. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

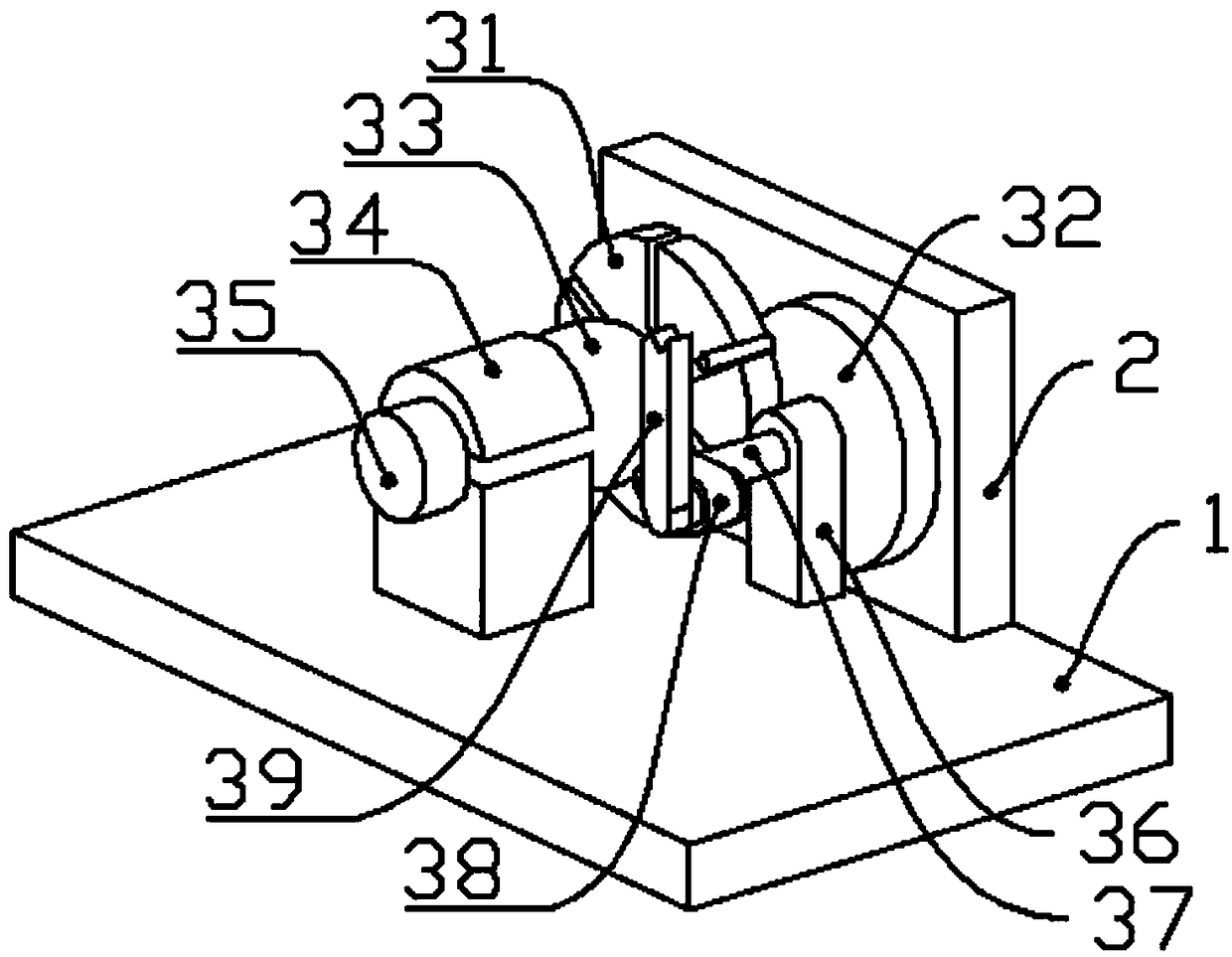

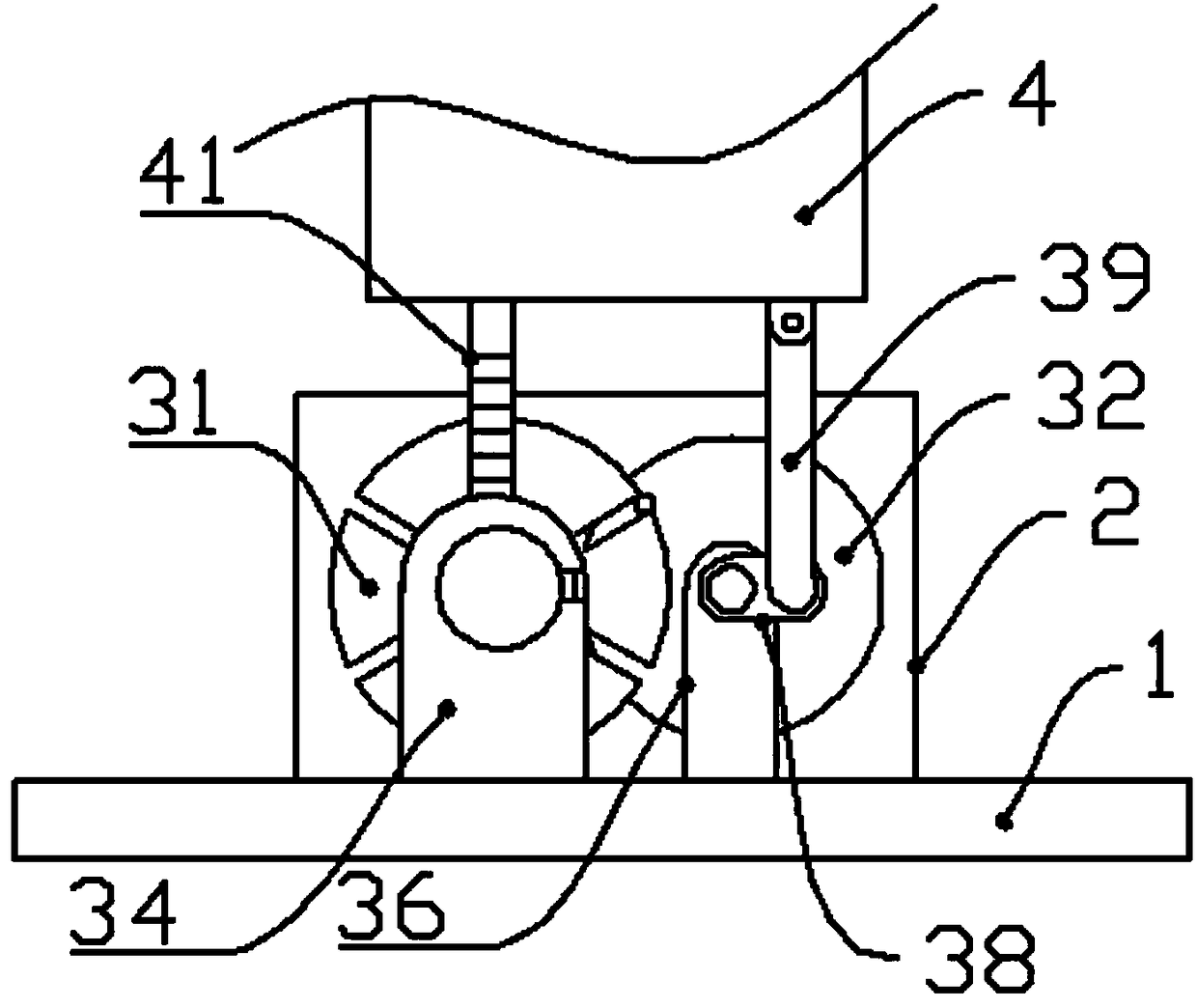

[0012] Such as figure 1 and figure 2 The jig for drawing the hole of a ball cage cage includes a base 1 for fixing on the workbench of a broaching machine, on which a back plate 2 is vertically fixed, and on the back plate 2 are pivotally fixed mating slaves. The movable sheave 31 and the driving pin wheel 32, the driven sheave 31 are fixedly connected to the ball cage holder seat 33, the ball cage holder seat 33 is connected to the cylindrical block 35 through a short axis, the driven sheave 31, the ball cage holder Seat 33, short shaft and cylinder stopper 35 are all coaxial, and described short shaft has a positioning block 34 that can be taken off; Described driving pin wheel 32 is connected to crank 38 through rotating shaft 36 on the side away from back plate 2, and rotating shaft 36 passes through support base 36, and one-way bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com