Integrated rod-shaped puffed grain food cutting and conveying machine

A technology of rice sticks and conveyors, applied in the directions of transportation and packaging, tubular objects, packaging, etc., can solve the problems of restricting production efficiency, high labor intensity, troublesome and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

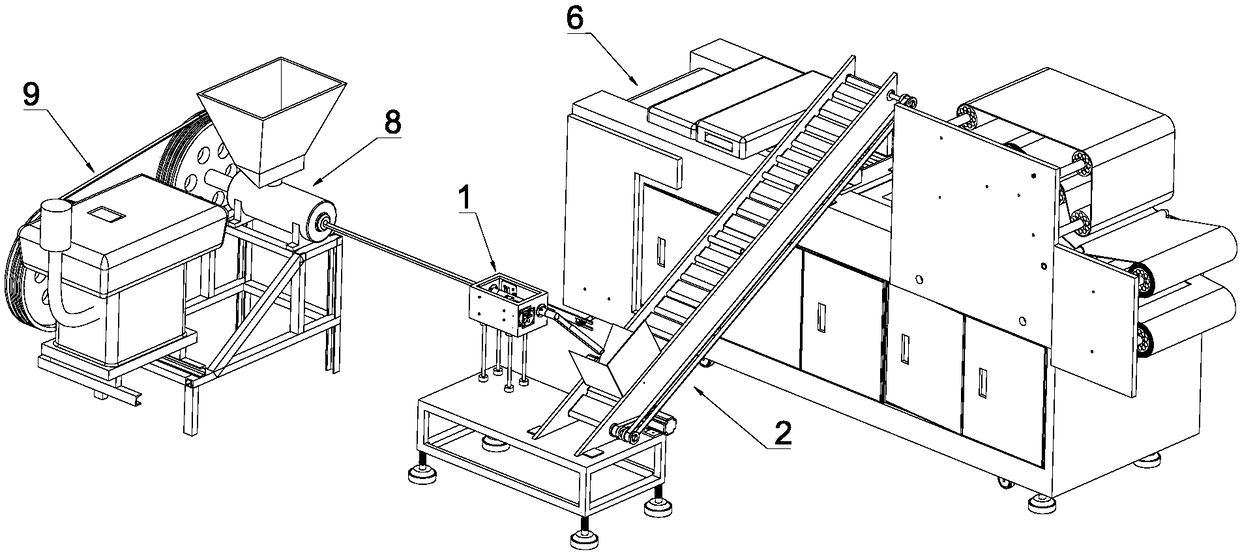

[0055] see figure 1 , Figure 6 , Figure 7 as well as Figure 8 The integrated glutinous rice stick cutting conveyor of the present invention includes a cutting module 1 for cutting the glutinous rice sticks 7 overflowing from the puffing machine 8 (the puffing machine 8 is driven by a diesel engine 9), and is used for cutting the glutinous rice sticks 7 between the cutting module 1 and packing The synchronous belt conveying module 2 that is carried out to the glutinous rice stick 7 between machine 6, the attitude adjustment module 3 that is used to adjust the attitude of the glutinous rice stick 7 on the synchronous belt conveying module 2 and the module 3 that is used to transfer the glutinous rice stick 7 from the synchronous belt conveying module 2 is transferred to the storage module 4 in the packing box 6-1 on the packing machine 6.

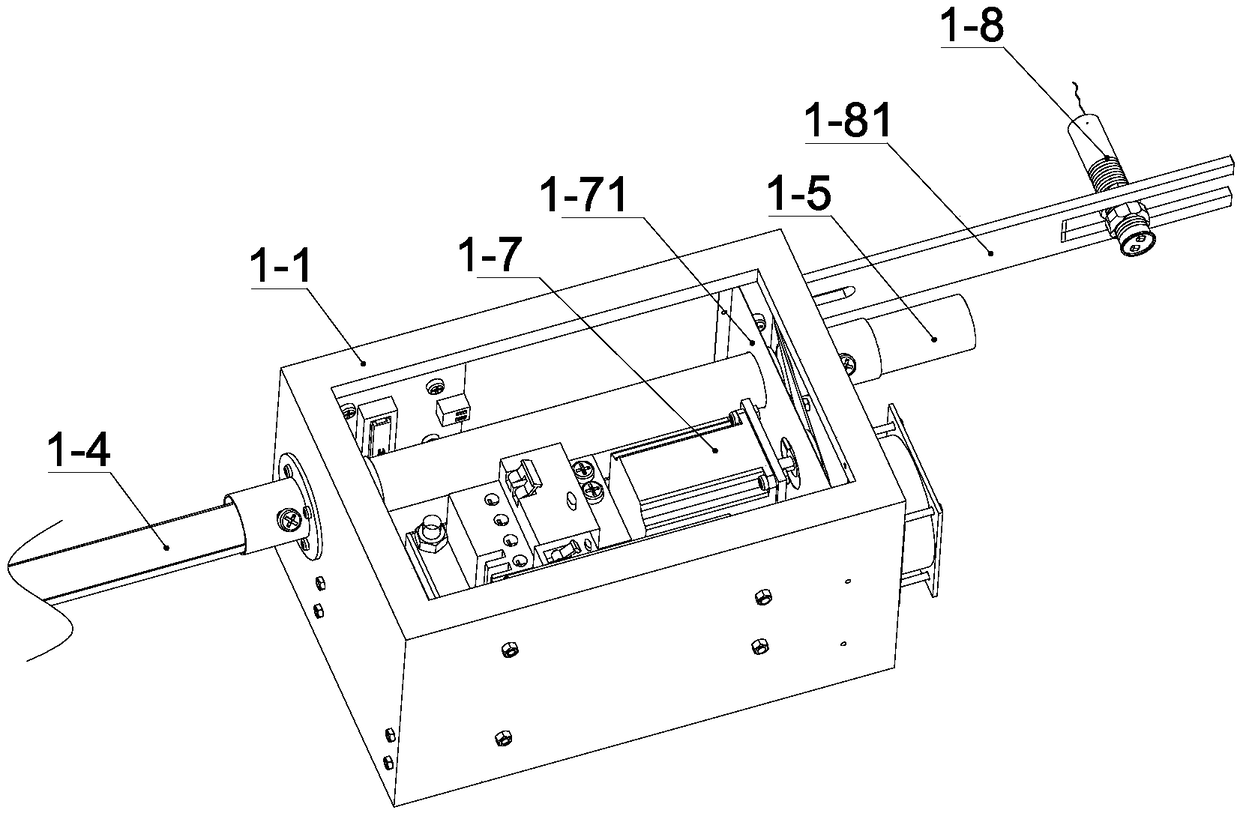

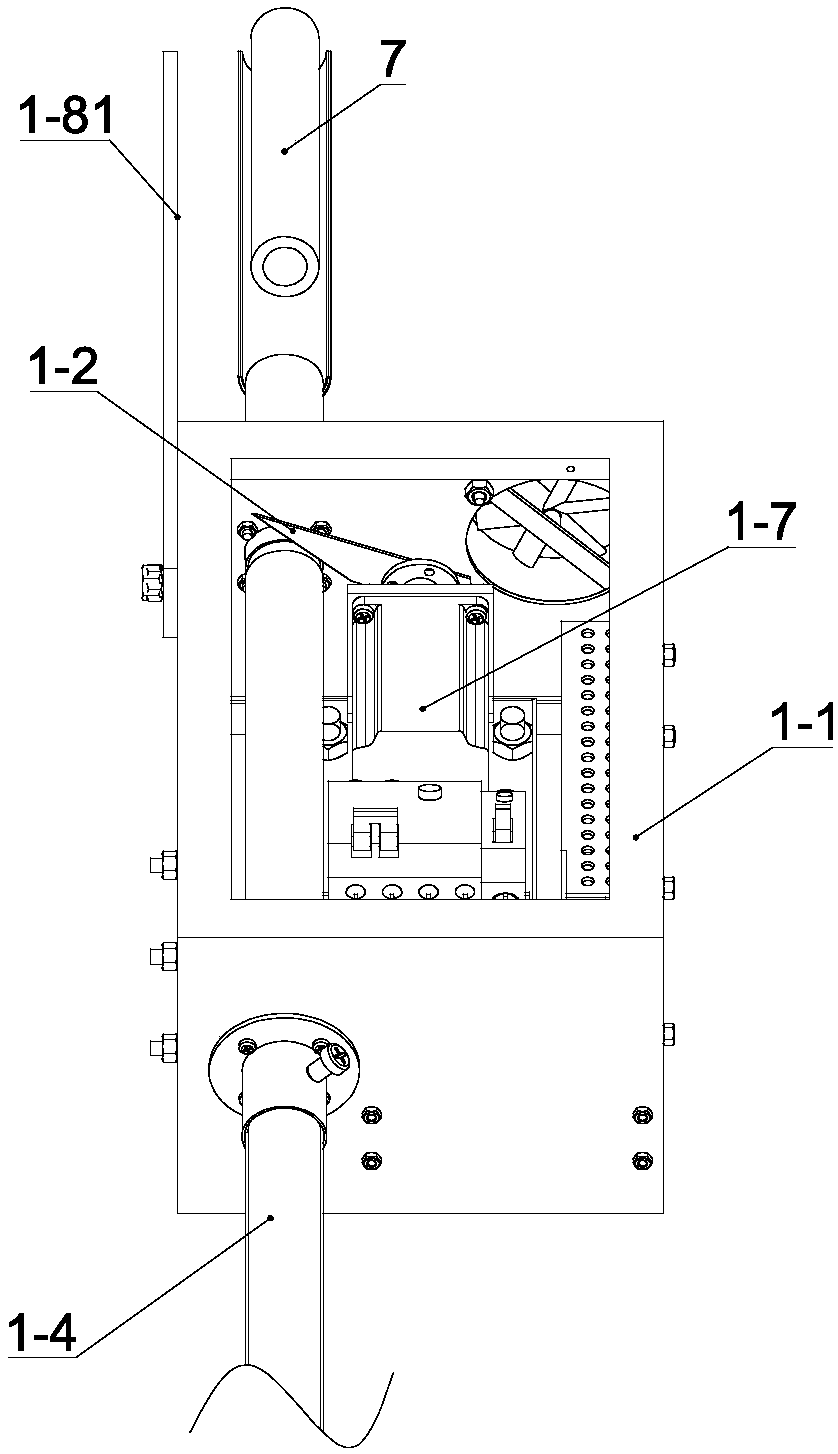

[0056] see Figure 2-Figure 5 , the cutting module 1 includes a box body 1-1, a glutinous rice stick cutting mechanism and a glutinou...

Embodiment 2

[0077] see Figure 23-Figure 27 The difference between this embodiment and Embodiment 1 is that the cutting drive mechanism described in this embodiment is a linear drive mechanism, and the linear drive mechanism is composed of an eccentric wheel 1-91 drive mechanism, and the eccentric wheel 1-91 drive mechanism It includes a third motor 1-9, an eccentric wheel 1-91 arranged on the output shaft of the motor, and a connecting piece 1-92, wherein one end of the connecting piece 1-92 is rotationally connected with the eccentric wheel 1-91, and the other end is connected with the cutting knife The fixed parts 1-3 are connected in rotation. During work, the third motor 1-9 drives the eccentric wheel 1-91 and the connecting piece 1-92 to rotate, and then drives the cutting knife fixing piece 1-3 that is rotatably connected with the connecting piece 1-92 to carry out lifting and cutting motion, thereby realizing the cutting of rice Cutting of stick 7. The benefit of such setting is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com