Material cutting, pipe driving and pipe drawing all-in-one machine

A technology of an all-in-one machine and a material-moving mechanism, which can be applied to other manufacturing equipment/tools, manufacturing tools, etc., and can solve the problems of reduced production efficiency, low degree of automation, and large labor and time consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the accompanying drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. The purpose of providing these embodiments is to make the disclosure of the present invention more thorough and comprehensive.

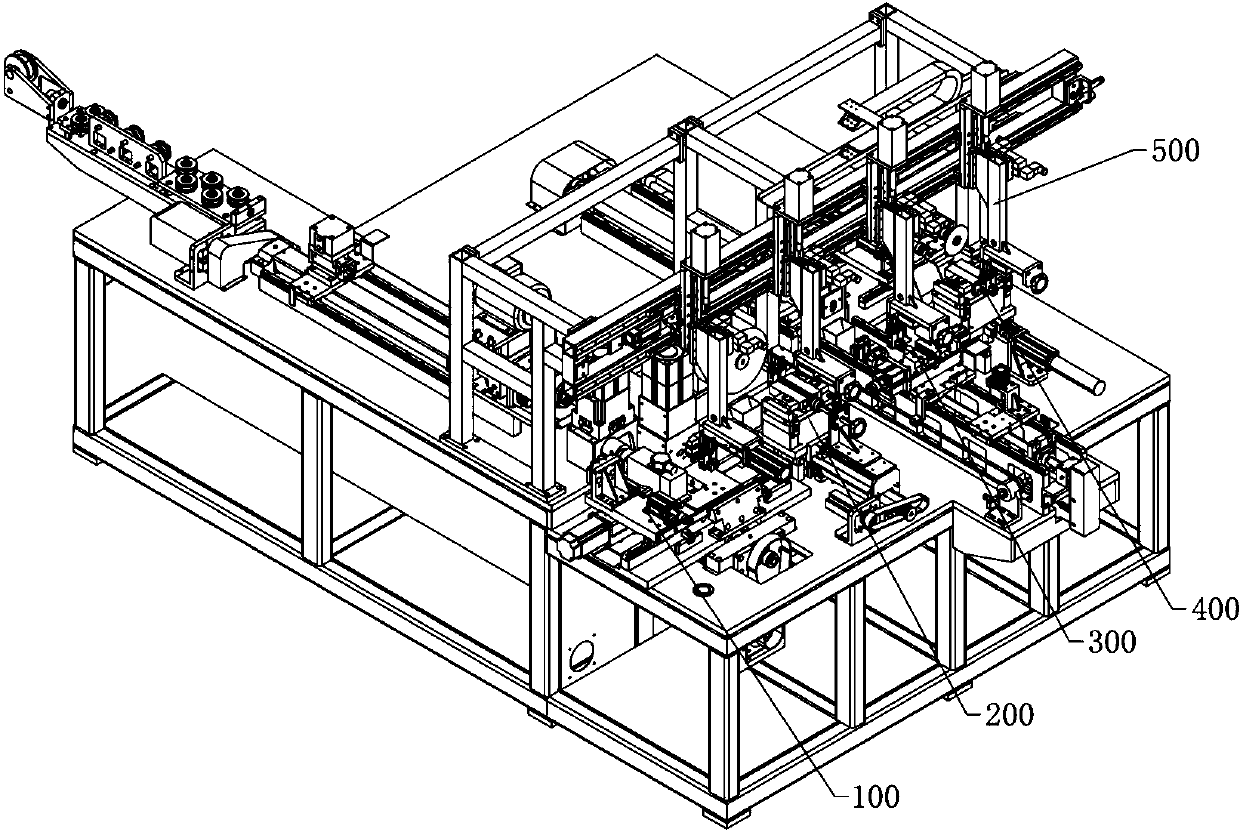

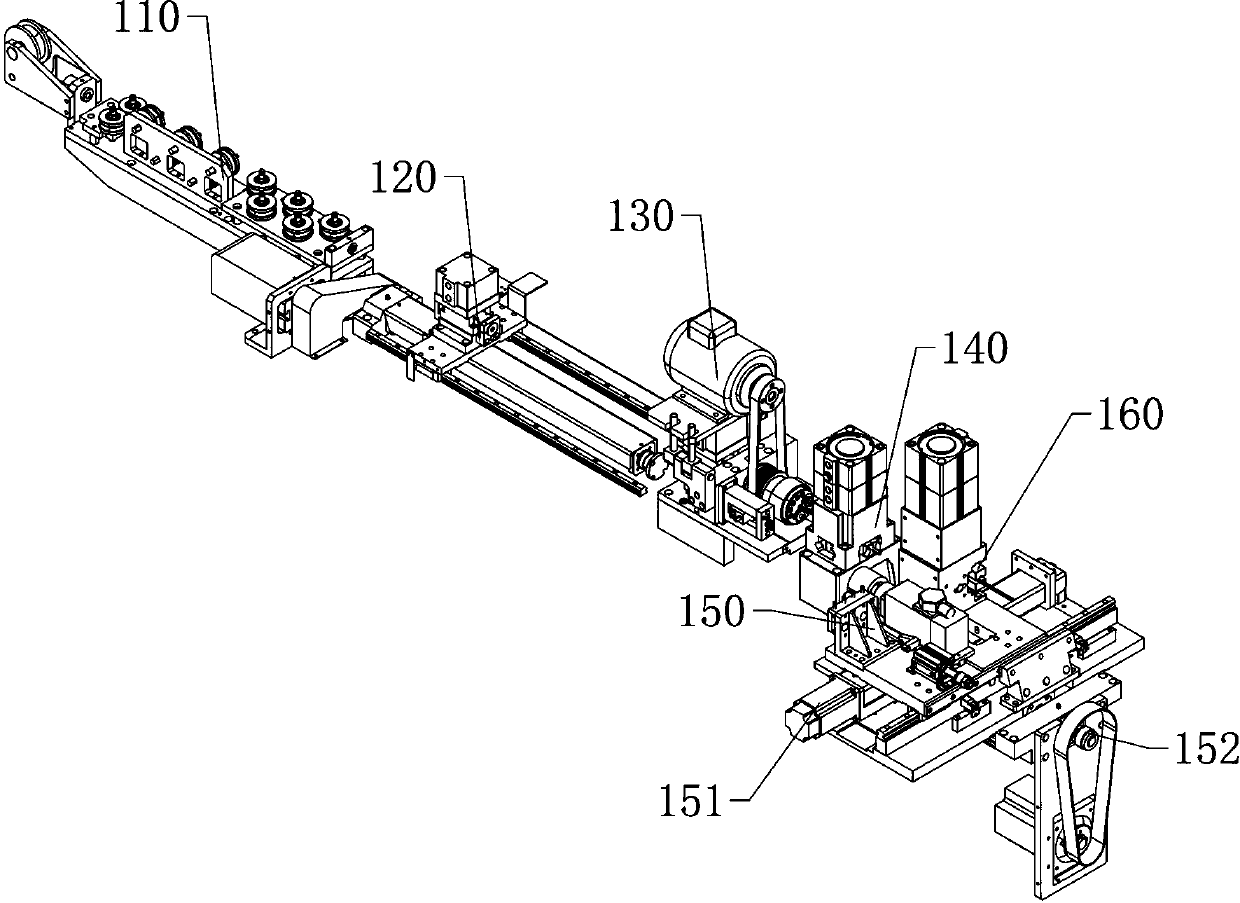

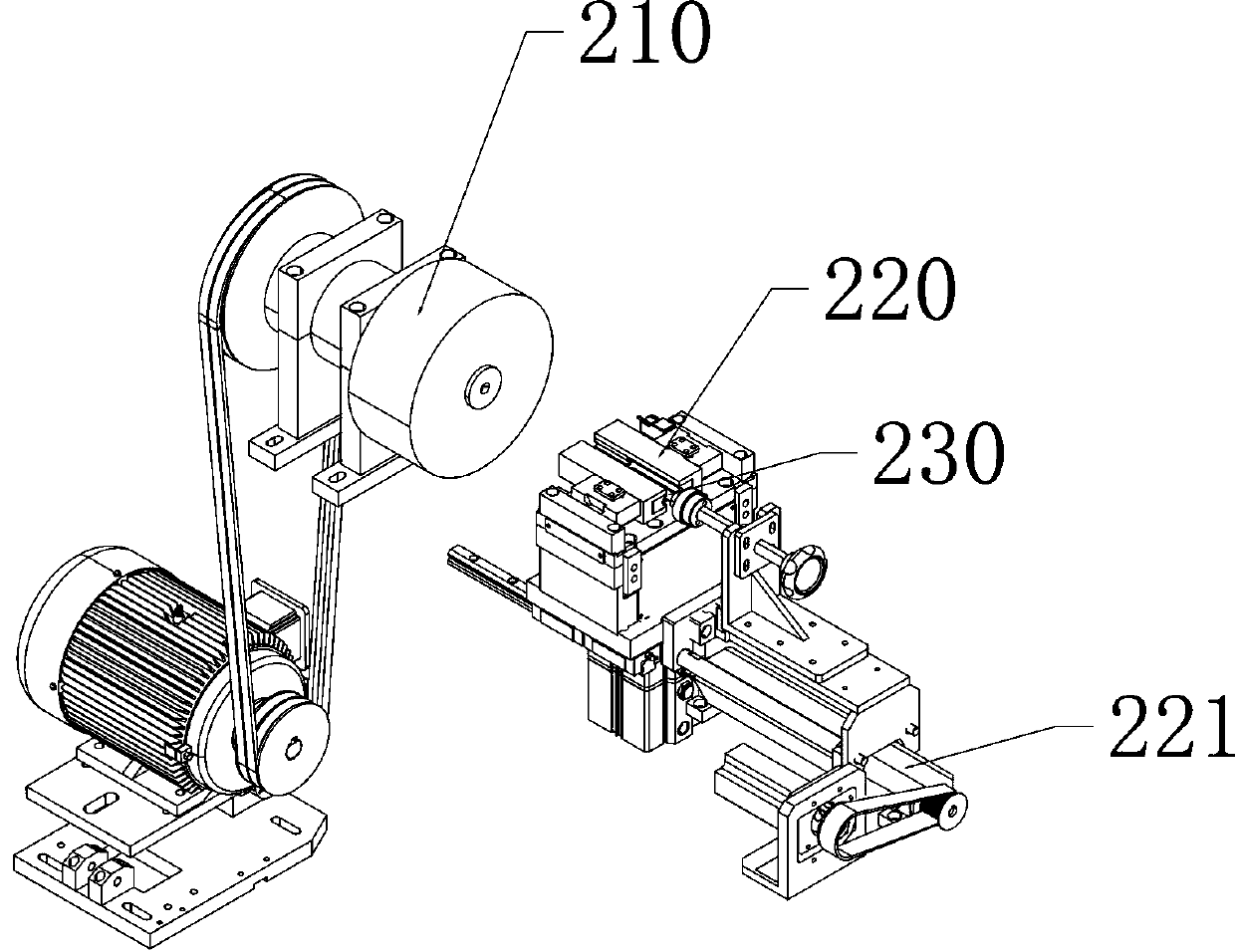

[0024] See attached figure 1 To attach Figure 9 As shown, in this embodiment, an integrated machine for cutting, drawing and pulling tubes includes a material shifting unit that can move back and forth laterally, and a material cutting unit 100, a tube cutting and shrinking unit 200, and a pulling unit arranged side by side in a horizontal direction. The pipe unit 300 and the cutting unit 400, wherein the material transfer unit is used to transfer pipes between various me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com