Stain-removing detergent

A technology for detergents and active agents, applied in the directions of detergent compounding agents, detergent compositions, organic cleaning compositions, etc., can solve the problems of poor decontamination effect of detergents, and achieve the effect of mild performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

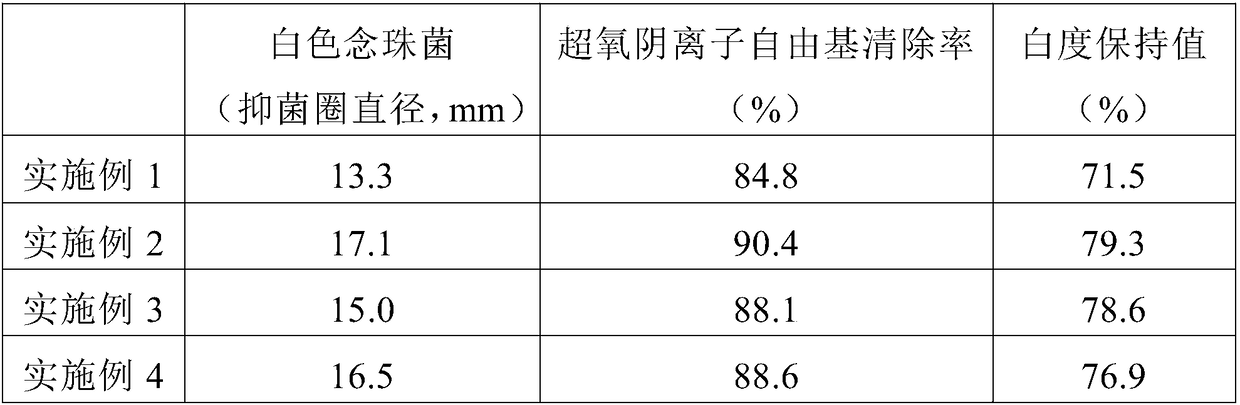

Examples

Embodiment 1

[0067] Heat 130 parts by weight of water to 70°C, add 5 parts by weight of dodecylamine polyoxyethylene ether, 8 parts by weight of N,N-di(hydroxyethyl)cocamide, 8 parts by weight of cocoamidopropyl Betaine and 2 parts by weight of sodium lauryl sulfate were mixed uniformly at a speed of 300r / min for 20 minutes to obtain a mixed solution; the mixed solution was cooled to 45°C, and then 0.8 parts by weight of tea saponin and 0.5 parts by weight of saponin were added in sequence. Seed extract, 0.7 parts by weight of Fructus Cnidii extract, 0.2 parts by weight of disodium edetate, and 0.15 parts by weight of sodium hydroxide were mixed uniformly at a speed of 300 r / min for 30 minutes to obtain a stain-removing detergent.

Embodiment 2

[0069] Heat 130 parts by weight of water to 70°C, add 5 parts by weight of dodecylamine polyoxyethylene ether, 8 parts by weight of biosurfactant, 8 parts by weight of N,N-di(hydroxyethyl)cocamide, 8 parts by weight of cocamidopropyl betaine and 2 parts by weight of sodium lauryl sulfate were mixed evenly at a speed of 300r / min for 20 minutes to obtain a mixed solution; the mixed solution was cooled to 45°C, and then 0.8 parts by weight of tea Saponin, 0.5 parts by weight of Sapindus chinensis extract, 0.7 parts by weight of Fructus Cnidii extract, 0.2 parts by weight of disodium edetate, and 0.15 parts by weight of sodium hydroxide are mixed evenly at a speed of 300r / min for 30min to obtain stain detergent.

[0070] The biosurfactant is a polyether surfactant.

[0071] The preparation method of the polyether surfactant is as follows: accurately weigh 60g of carvacrol, 20g of cinnamyl alcohol and 1g of potassium hydroxide catalyst, add it to a 2L reaction kettle, replace it w...

Embodiment 3

[0073] Heat 130 parts by weight of water to 70°C, add 5 parts by weight of dodecylamine polyoxyethylene ether, 8 parts by weight of biosurfactant, 8 parts by weight of N,N-di(hydroxyethyl)cocamide, 8 parts by weight of cocamidopropyl betaine and 2 parts by weight of sodium lauryl sulfate were mixed evenly at a speed of 300r / min for 20 minutes to obtain a mixed solution; the mixed solution was cooled to 45°C, and then 0.8 parts by weight of tea Saponin, 0.5 parts by weight of Sapindus chinensis extract, 0.7 parts by weight of Fructus Cnidii extract, 0.2 parts by weight of disodium edetate, and 0.15 parts by weight of sodium hydroxide are mixed evenly at a speed of 300r / min for 30min to obtain stain detergent.

[0074] The biosurfactant is a polyether surfactant.

[0075] The preparation method of the polyether surfactant is as follows: accurately weigh 60 g of carvacrol and 1 g of potassium hydroxide catalyst, add it into a 2L reaction kettle, replace it with nitrogen for 6 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com