Microcarrier biological reaction tank and method for culturing porcine circovirus type II by microcarrier biological reaction tank

A biological reaction and microcarrier technology, applied in the direction of supporting/immobilizing microorganisms, bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, etc., can solve the problem that the liquid cannot be completely drained and the adjustment is inaccurate , loss of carrier and other issues, to achieve the effect of conveniently filtering the carrier, increasing the cell density, and increasing the adherence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

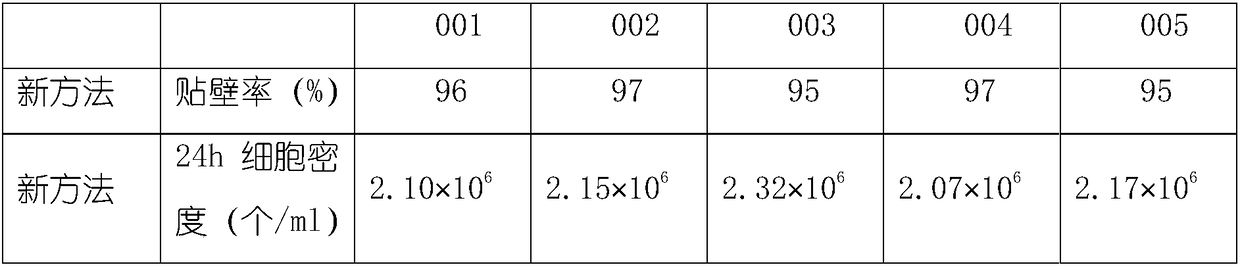

Examples

Embodiment Construction

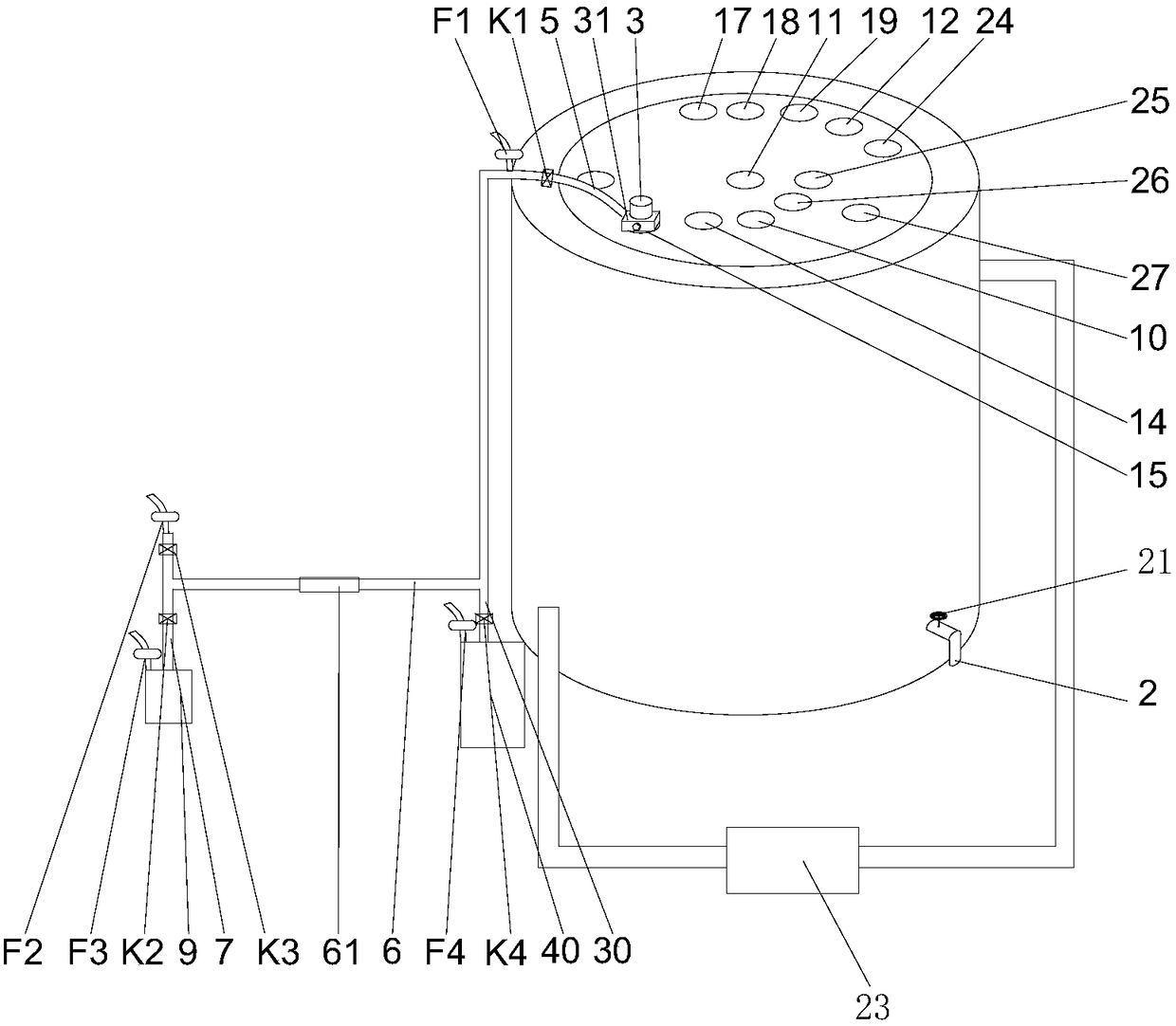

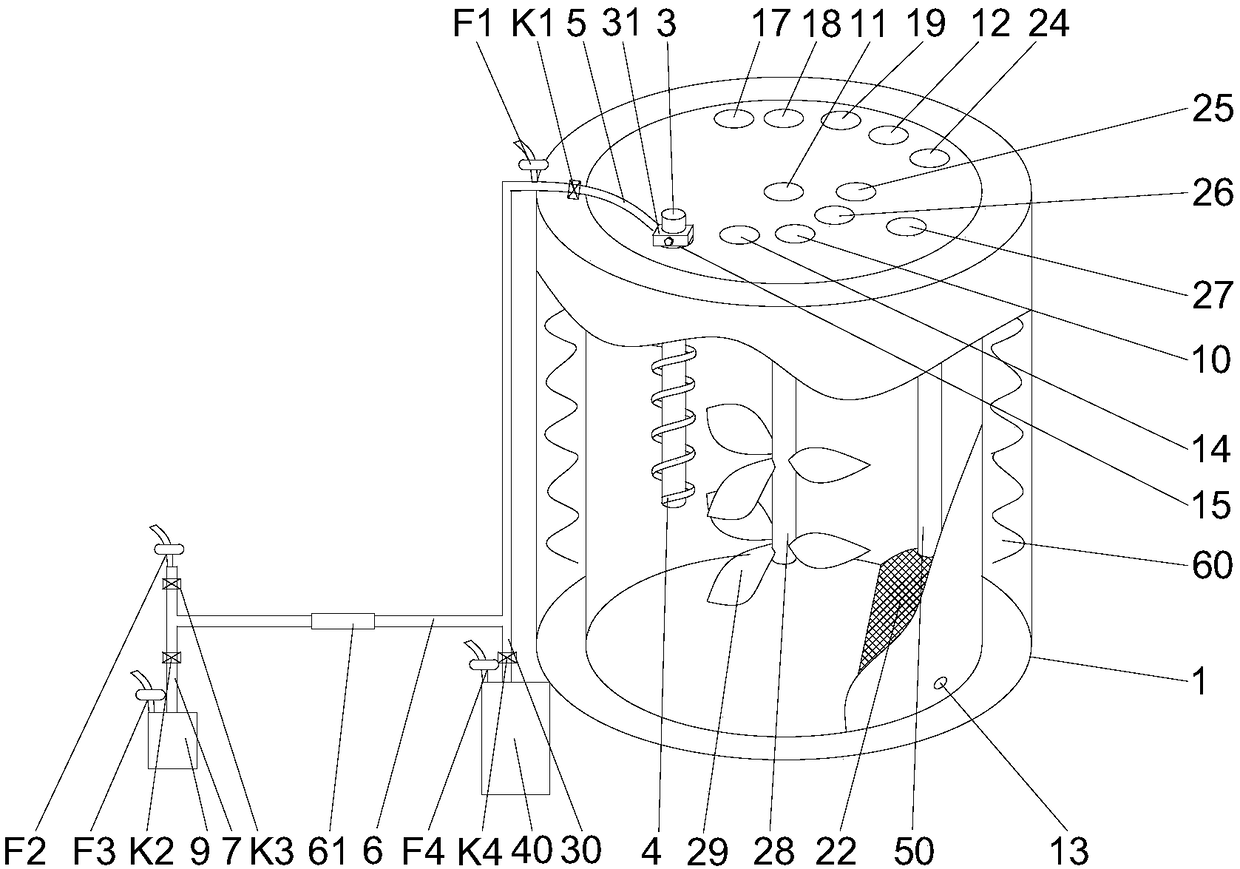

[0038] Such as figure 1 As shown in or 2, the present invention discloses a microcarrier bioreactor tank, which includes a tank body 1, a stirrer, a biological reaction detection electrode, and a defoaming device are arranged in the tank body 1, and the upper surface of the tank body 1 is correspondingly provided with a stirring The device installation port 11, the electrode interface and the defoaming device interface 12, the agitator is used for stirring the liquid in the tank body 1, the bottom of the tank body 1 is provided with a discharge port 13, and the discharge port 13 is extended with a discharge pipe 2, and the discharge pipe 2 is provided with There is a discharge valve 21, and the inner wall of the tank body 1 is provided with a filter screen 22 corresponding to the discharge port 13,

[0039] The upper surface of the tank body 1 is also provided with an air inlet port and a liquid material interface. The air inlet port is used to feed gas into different position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com