PECVD graphite boat with anti-oxidation coating pipe and manufacturing method

A technology of anti-oxidation coating and manufacturing method, which is applied in the field of graphite boats, can solve the problems of waste and high cost, and achieve the effects of stable and improved product quality, long service life and avoiding low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

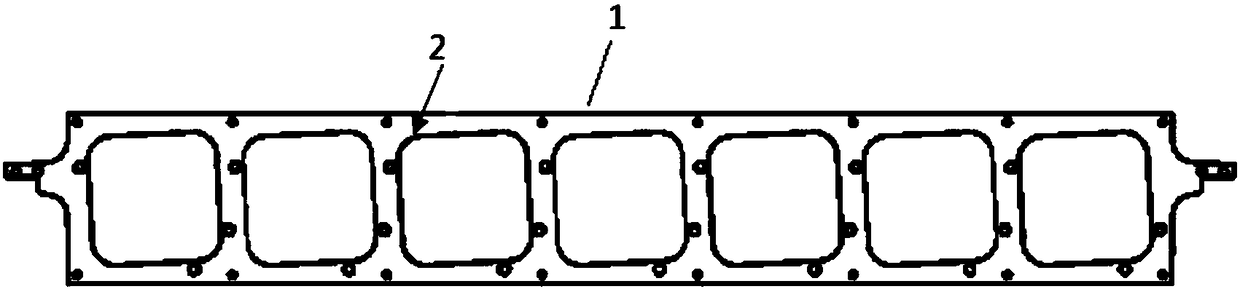

[0023] Such as figure 1 As shown, a tubular PECVD graphite boat with an anti-oxidation coating is impregnated with resin in the graphite boat blank. The graphite boat blank is cured, processed, and high-temperature treated to fully carbonize the resin and form a layer Anti-oxidation film2.

[0024] The anti-oxidation film is a uniform film with a thickness of 2-4 μm.

Embodiment 2

[0026] Novel graphite boat of the present invention is specifically realized through the following steps:

[0027] A kind of manufacture method of tube type PECVD graphite boat with anti-oxidation coating, comprises the following steps:

[0028] 1) First place the graphite raw material in a vacuum furnace, perform high-temperature purification at a temperature of 2300 ° C, remove the internal impurities of the graphite raw material, and form a graphite boat blank;

[0029] 2) put the prepared graphite boat blank into the prepared resin and soak for 1.5 hours, so that the resin is completely impregnated into the material interior of the graphite boat blank;

[0030] 3) The impregnated graphite boat blank is heated to a temperature of 100° C. in a graphite oven, and is kept for 2 hours for curing treatment to form a blank;

[0031] 4) Processing the solidified green body into finished products;

[0032] 5) Put the processed finished product into a vacuum furnace for high tempe...

Embodiment 3

[0035] A kind of manufacture method of tube type PECVD graphite boat with anti-oxidation coating, comprises the following steps:

[0036] 1) First place the graphite raw material in a vacuum furnace, and perform high-temperature purification at a temperature of 2350 ° C to remove internal impurities of the graphite raw material to form a graphite boat blank;

[0037] 2) put the prepared graphite boat blank into the prepared resin and soak for 1.7 hours, so that the resin is completely impregnated into the material interior of the graphite boat blank;

[0038] 3) The impregnated graphite boat blank is heated up to 110° C. in a graphite oven, and kept for 2.5 hours for curing treatment to form a green body;

[0039] 4) Processing the solidified green body into finished products;

[0040] 5) Put the finished product into a vacuum furnace for high temperature treatment at 1450°C, keep it warm for 2 hours to fully carbonize the resin, and form a uniform film with a thickness of 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com