A kind of ultra-high molecular weight polyethylene film split fiber and its preparation method

An ultra-high molecular weight, polyethylene film technology, applied in the field of polyethylene fibers, can solve the problems of easy fuzzing, breakage, winding rolls, and low degree of fibrillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

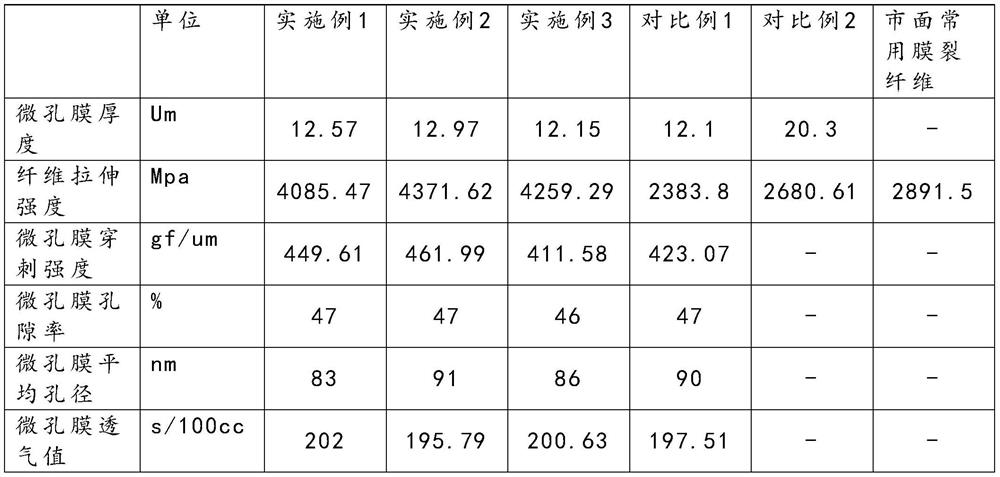

Examples

preparation example Construction

[0021] The embodiment of the present invention provides a method for preparing ultra-high molecular weight polyethylene split fibers, comprising the following steps:

[0022] S1: Put polyethylene in a reaction kettle for melting, extrude the polyethylene melt through a twin-screw at a certain speed and a die, cool and crystallize the polyethylene melt on the surface of a cold roll at a certain speed to obtain a cast sheet .

[0023] S2: The cast sheet is preheated and stretched bidirectionally synchronously, and then after being recovered by the extractant, it is dried and shaped to obtain a polyethylene microporous diaphragm.

[0024] In this step, under the action of biaxial stretching, from the microscopic point of view, the disordered molecules and molecular segments are gradually arranged in an orderly manner; from the macroscopic point of view, the film does not contact any roller during the stretching process. Therefore, a film without scratches can be obtained without...

Embodiment 1

[0035] Put polyethylene with a molecular weight of 600,000-2,000,000 in a reactor for melting, extrude the polyethylene melt through a twin-screw and die head at 100-150 rpm, and transfer the polyethylene melt at 4-7 rpm / min of chilled roll surface cooling and crystallization to obtain cast sheets;

[0036] After the cast sheet is preheated at 180-200°C, it is stretched in two directions synchronously. The longitudinal stretching ratio is 1-3 times, and the transverse stretching ratio is 4-8 times. After being recovered by the extractant, it is dried and shaped to obtain Polyethylene microporous membrane;

[0037] Cut the polyethylene microporous membrane into strips of 0.5-0.8 cm, and after drying, perform longitudinal stretching again at 110-120°C at a high temperature of 10 times to obtain ultra-high molecular weight polyethylene split fibers 1.

Embodiment 2

[0039] Put polyethylene with a molecular weight of 600,000-2,000,000 in a reactor for melting, extrude the polyethylene melt through a twin-screw and die head at 100-150 rpm, and transfer the polyethylene melt at 4-7 rpm / min of chilled roll surface cooling and crystallization to obtain cast sheets;

[0040] After the cast sheet is preheated at 180-200°C, it is stretched in two directions synchronously. The longitudinal stretching ratio is 1-3 times, and the transverse stretching ratio is 4-8 times. After being recovered by the extractant, it is dried and shaped to obtain Polyethylene microporous membrane;

[0041] Cut the polyethylene microporous diaphragm into 0.5-0.8 cm strip diaphragms, after drying, carry out longitudinal stretching again at 110-120°C at a high temperature, and the stretching ratio is 11 times to obtain ultra-high molecular weight polyethylene film split fibers 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com