A kind of preparation method of aramid pulp and the prepared aramid pulp

A technology of aramid pulp and pulp, which is applied in the field of organic fiber and its preparation, can solve the problems of mixed metal debris, long process flow, and impure products, and accelerate fiber breakage, fibrillation, and fibrillation High degree of hairiness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

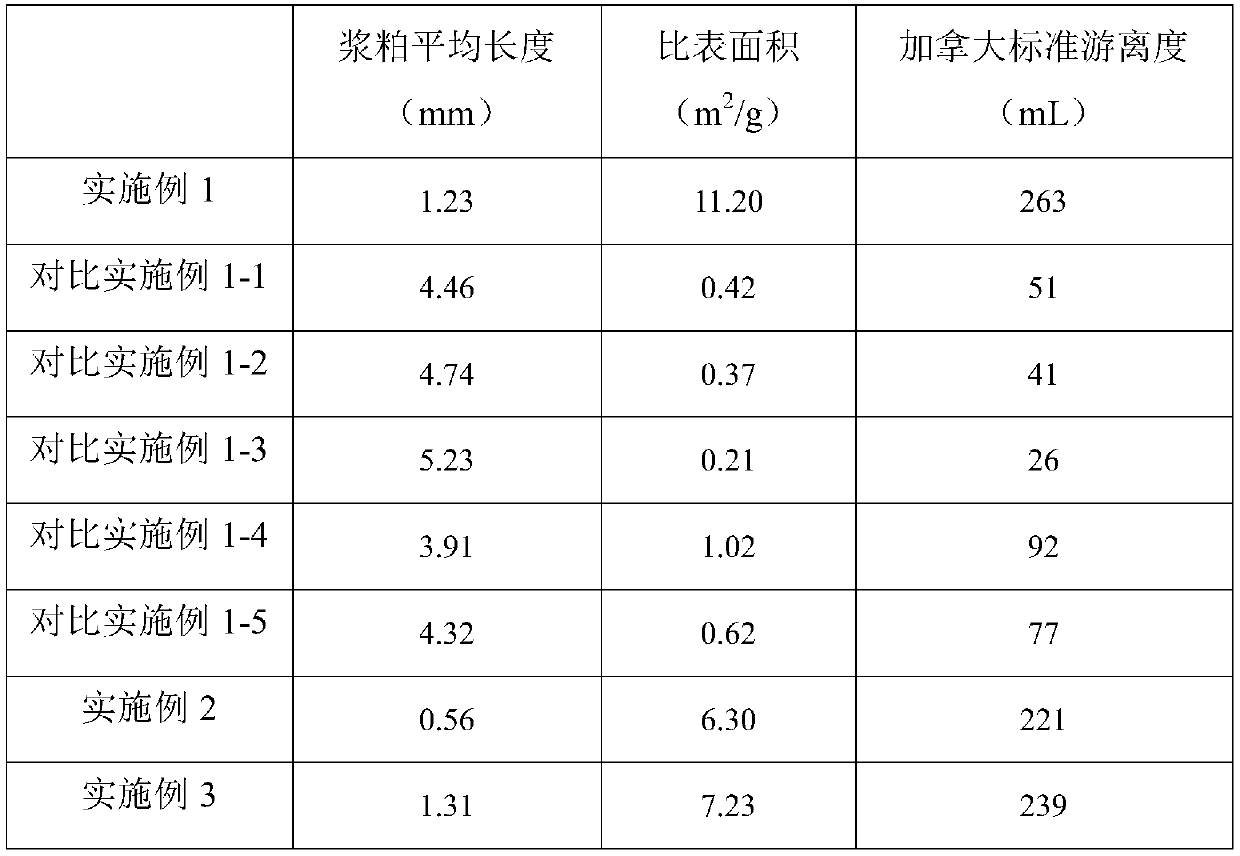

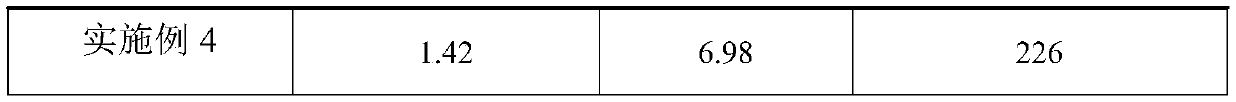

Examples

Embodiment 1

[0030] (1) Corona treatment: the aramid fiber is subjected to corona treatment, the length of the aramid fiber is 6mm, the voltage of the corona treatment is 10000V, the frequency is 15KHz, the distance between the electrode rod and the aramid fiber is 5mm, and the treatment time is 10s;

[0031] (2) humidification treatment: the aramid fibers obtained in the above step (1) are sprayed with water, and the mass consumption of water is 200% of the mass consumption of the aramid fibers;

[0032] (3) Preparation of pulp: the aramid fiber obtained in the above step (2) enters the high-speed rotary pulverizer under the drive of the air, the temperature of the air is 90°C, and the flow rate of the air is 3000m 3 / h, the rotation speed of the rotor in the pulverizer is 3000rpm, and dry pulping is carried out to obtain aramid fiber pulp.

Embodiment 2

[0044] (1) Corona treatment: the aramid fiber is subjected to corona treatment, the length of the aramid fiber is 3mm, the voltage of the corona treatment is 5000V, the frequency is 15KHz, the distance between the electrode rod and the aramid fiber is 1mm, and the treatment time is 5s;

[0045] (2) humidification treatment: the aramid fibers obtained in the above step (1) are sprayed with water, and the mass consumption of water is 300% of the mass consumption of the aramid fibers;

[0046] (3) Preparation of pulp: the aramid fiber obtained in the above step (2) enters the high-speed rotary pulverizer under the drive of the air, the temperature of the air is 120°C, and the flow rate of the air is 300m 3 / h, the rotation speed of the rotor in the pulverizer is 5000rpm, and dry pulping is carried out to obtain aramid pulp.

Embodiment 3

[0048] (1) Corona treatment: the aramid fiber is subjected to corona treatment, the length of the aramid fiber is 8mm, the voltage of the corona treatment is 15000V, the frequency is 25KHz, the distance between the electrode rod and the aramid fiber is 10mm, and the treatment time is 15s;

[0049] (2) humidification treatment: the aramid fibers obtained in the above step (1) are sprayed with water, and the mass consumption of water is 300% of the mass consumption of the aramid fibers;

[0050] (3) Preparation of pulp: the aramid fiber obtained in the above step (2) enters the high-speed rotary pulverizer under the drive of the air, the temperature of the air is 50°C, and the flow rate of the air is 6000m 3 / h, the rotation speed of the rotor in the pulverizer is 5000rpm, and dry pulping is carried out to obtain aramid pulp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com