Controllable mixed nano filament filter paper as well as preparation method and application thereof

A technology of nanofibrils and filter paper, which is applied in the field of adjustable mixed nanofibril filter paper and its preparation, can solve the problems of complex process, unfavorable process requirements regulation, environmental pollution, etc., and achieve high degree of fibrillation, The effect of wide range of intercepted particle size and high dry strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

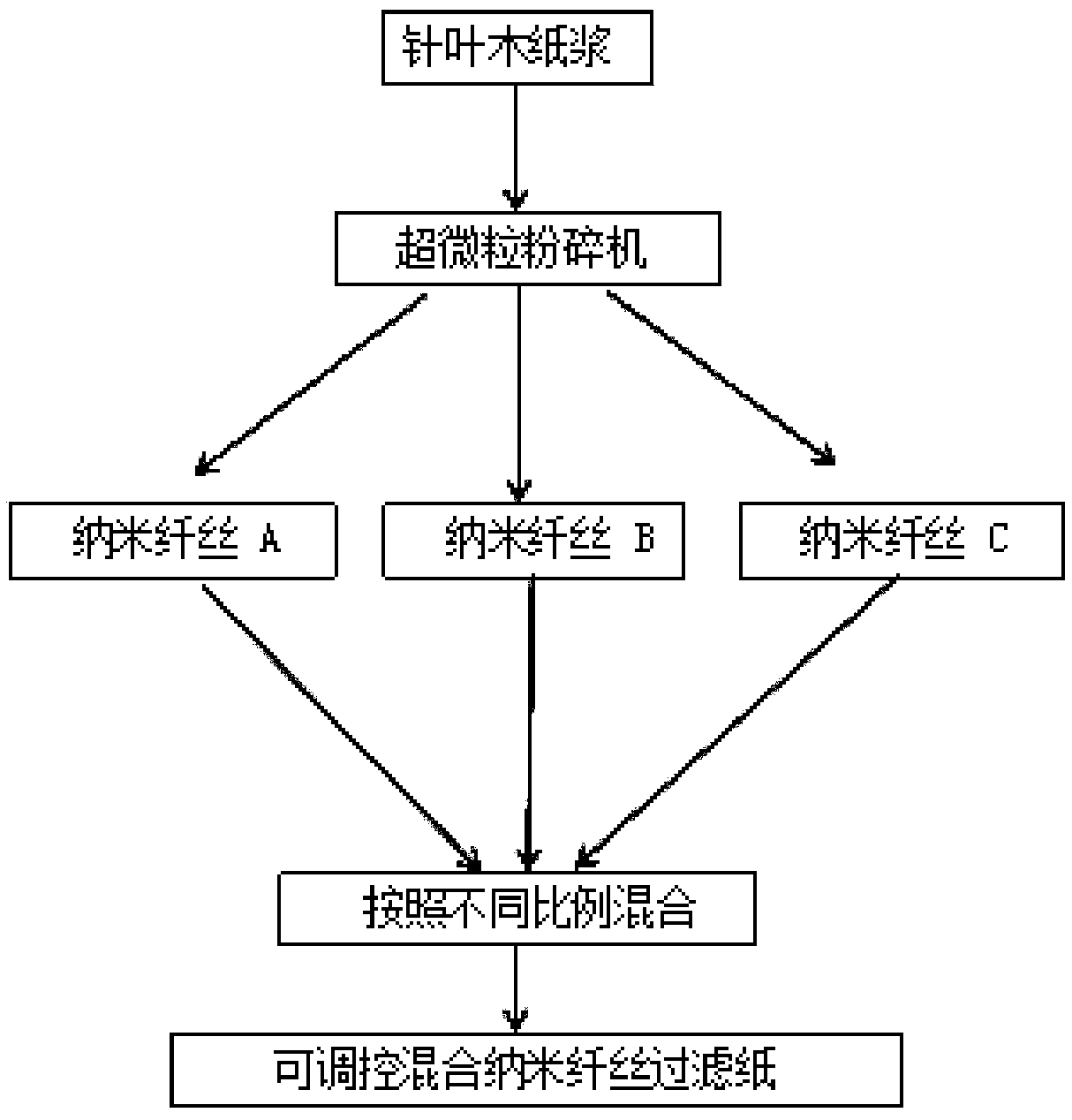

[0029] A kind of plant micro-nano fibril filter paper, its preparation method is as follows:

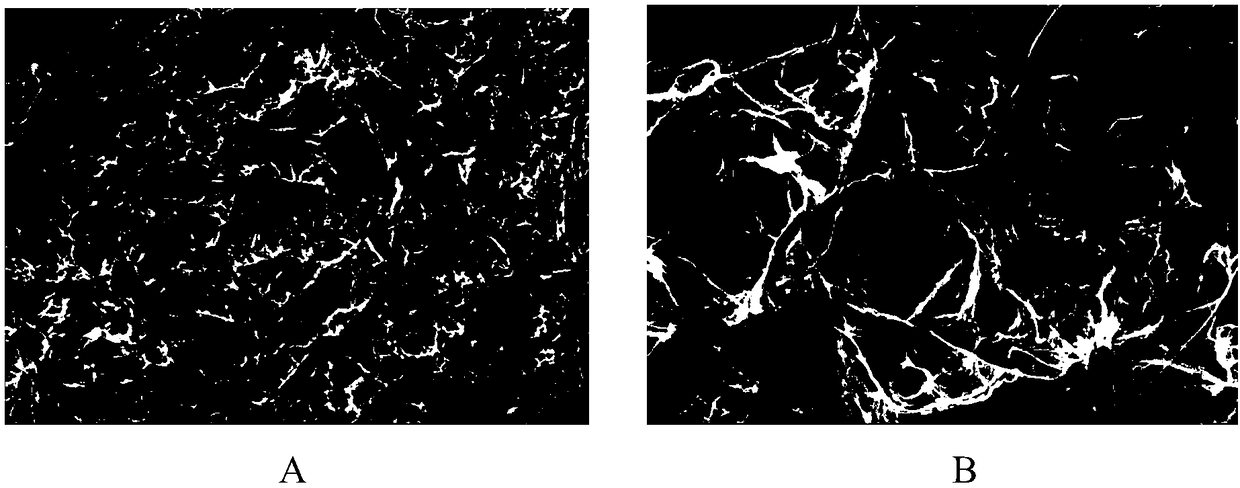

[0030] (1) Using softwood pulp as raw material to prepare pulp with a mass concentration of 0.1%, and then a superfine pulverizer with a gap of 0.1 μm and a rotation speed of 100 r / min (Japan Masuko Sangyo Co., Ltd., model: MKCA6-2J) Under the action of grinding for 5 cycles, the plant micro-nanofibrils A were prepared.

[0031] (2) Using softwood pulp as raw material to prepare pulp with a mass concentration of 0.1%, and then grinding for 25 cycles under the action of an ultrafine pulverizer with a gap of -100 μm and a rotational speed of 1800 r / min to prepare plant micro-nano fibers wire B.

[0032] (3) Using softwood pulp as raw material to prepare pulp with a mass concentration of 0.1%, and then grinding for 70 cycles under the action of an ultrafine pulverizer with a gap of -200 μm and a rotational speed of 1800 r / min to prepare plant micro-nano fibers wire C.

[0033] (4) Th...

Embodiment 2

[0036] A controllable hybrid nanofibril filter paper, the preparation method of which is as follows:

[0037] (1) Using softwood pulp as raw material to prepare pulp with a mass concentration of 5%, and then grinding for one cycle under the action of a superfine pulverizer with a gap of 150 μm and a rotational speed of 1000 r / min to prepare nanofibrils A.

[0038] (2) Using softwood pulp as raw material to prepare pulp with a mass concentration of 5%, and then grinding for 50 cycles under the action of an ultrafine pulverizer with a gap of 0.1 μm and a rotational speed of 1500 r / min to prepare nanofibrils B .

[0039](3) Use coniferous wood pulp as a raw material to make pulp with a mass concentration of 0.1%, and then grind for 50 cycles under the action of an ultrafine pulverizer with a gap of -100 μm and a speed of 2000 r / min to prepare nanofibrils c.

[0040] (4) The nanofibrils of nanofibrils A, nanofibrils B, and nanofibrils C are prepared according to the ratio of 40:...

Embodiment 3

[0043] An adjustable mixed nanofibril filter paper, the preparation method of which is as follows:

[0044] (1) Use coniferous wood pulp as a raw material to make pulp with a mass concentration of 10%, and then grind for 10 weeks under the action of an ultrafine pulverizer with a gap of 100 μm and a rotating speed of 50 r / min to prepare nanofibrils A .

[0045] (2) Use coniferous wood pulp as a raw material to make pulp with a mass concentration of 10%, and then grind for 30 cycles under the action of an ultrafine pulverizer with a gap of -50 μm and a rotating speed of 1500 r / min to prepare nanofibrils B .

[0046] (3) Use coniferous wood pulp as a raw material to make pulp with a mass concentration of 10%, and then grind for 50 cycles under the action of an ultrafine pulverizer with a gap of -200 μm and a rotating speed of 2500r / min to prepare nanofibrils C .

[0047] (4) The nanofibrils of nanofibrils A, nanofibrils B, and nanofibrils C are prepared according to the ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com