Dredging vehicle for cleaning sewer at inspection well

A technology for sewers and dredging vehicles, applied in waterway systems, water supply devices, buildings, etc., can solve the problems of slow operation, great odor, unfavorable treatment, etc., and achieve the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

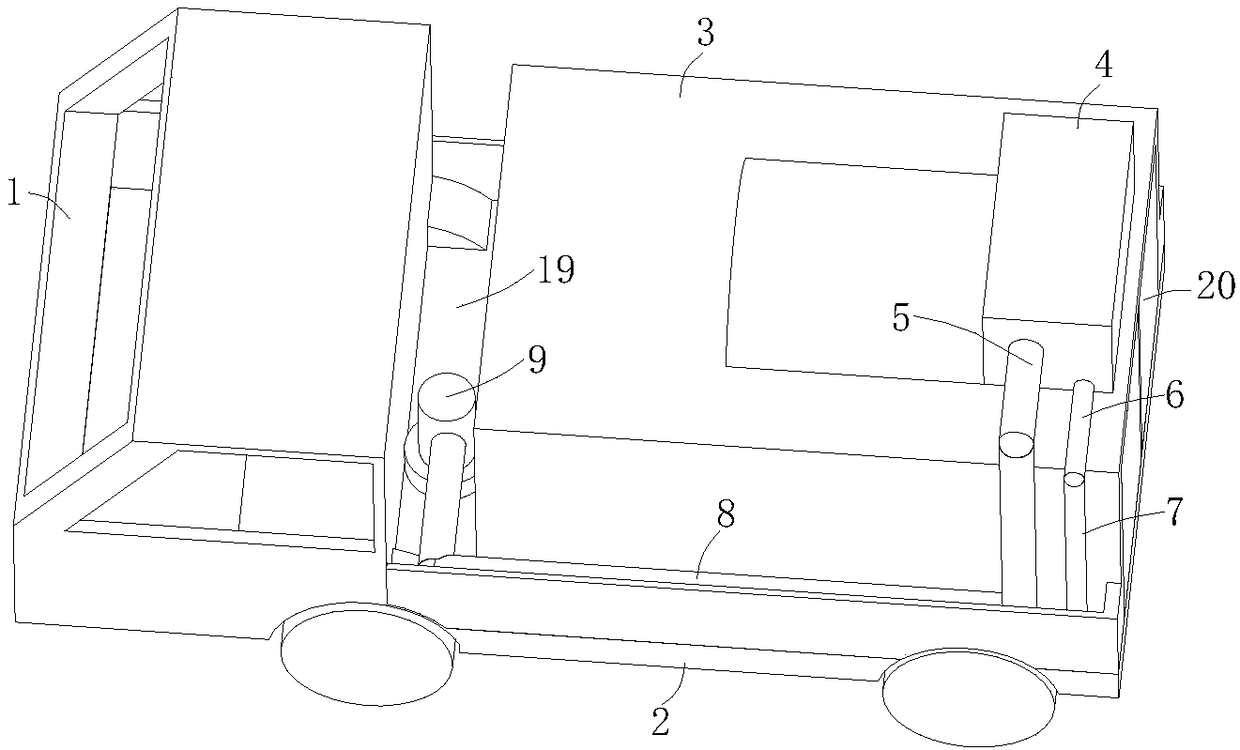

[0019] Such as Figure 1 to Figure 4 As shown, a dredging vehicle for cleaning the sewer at the inspection shaft includes a tractor head 1, the tail of the tractor head 1 is connected and installed with a chassis 2, and a sealed silt collection box 3 is arranged on the chassis 2, and the silt collection box 3 is provided with The screw press sludge dehydrator 4 is provided with a sludge inlet 5, a compressed sludge discharge outlet (not shown in the figure) and a squeeze sewage discharge outlet 6, and the compressed sludge discharge outlet is located in the sludge collection box 3. The sewage outlet 6 is connected with the sewage pipe 7 on the outside of the sludge collection box 3;

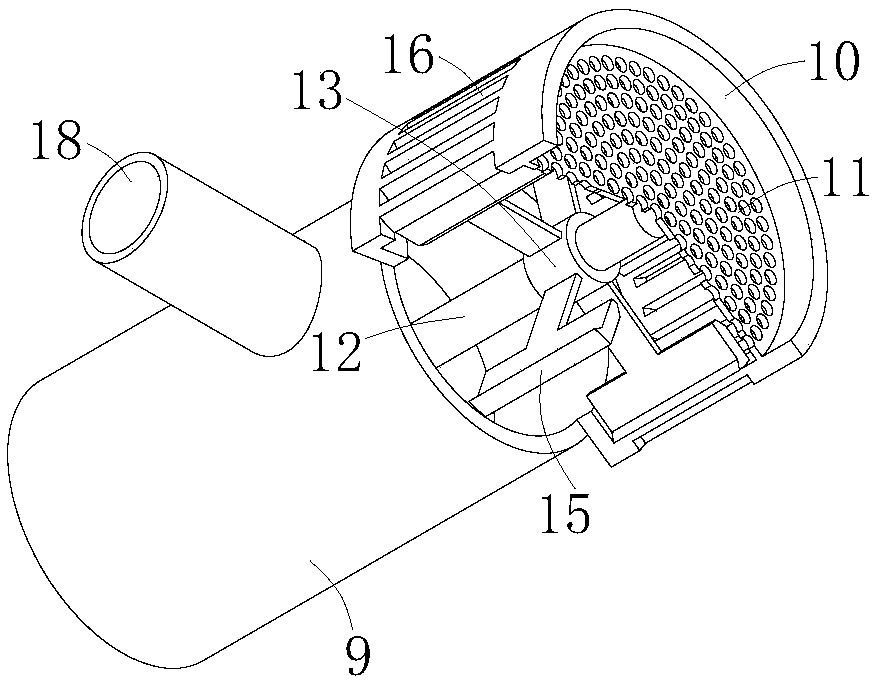

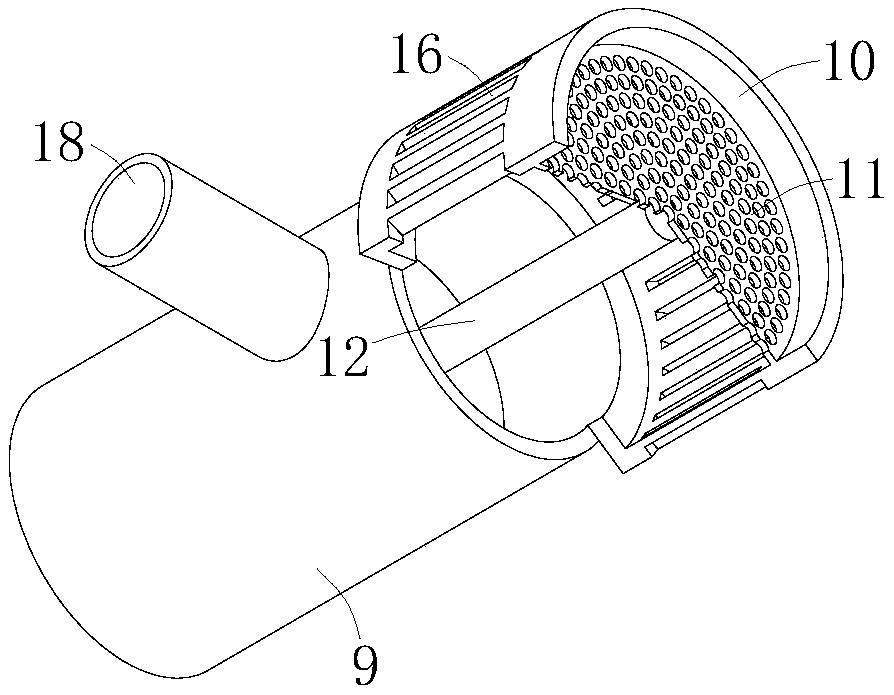

[0020] The sludge inlet 5 is connected to the submersible sludge pump 9 through a hose 8. The submersible sludge pump 9 is a product of the prior art. A water pump cover 10 is installed on the outside of the submersible sludge pump 9. Instructions are required. The tractor head 1, the chassis 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com