Variable stiffness tuned mass damper with dry friction plate

A technology of tuned mass damping and dry friction, which is applied in building components, building structures, and earthquake resistance. It can solve the problems of poor frequency vibration reduction, high engineering cost, and narrow effective frequency band, and achieve broad market promotion and application prospects. , reduce the cost, the effect of simple form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

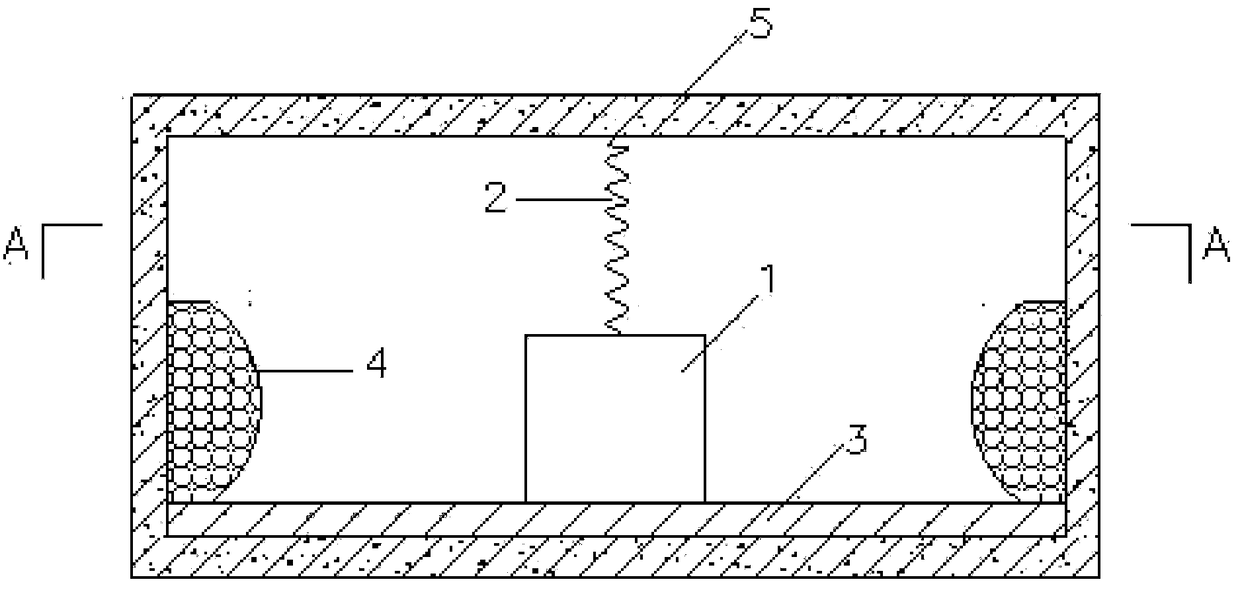

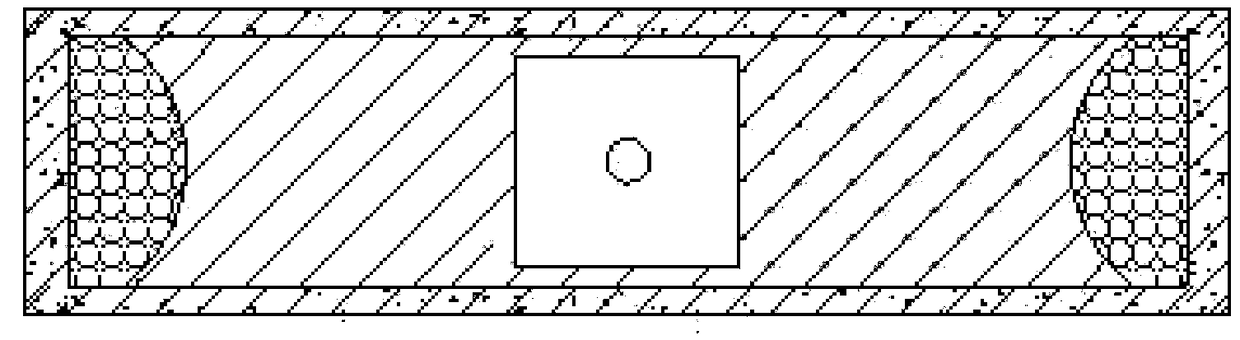

[0018] Such as figure 1 and figure 2 As shown, a variable stiffness tuned mass damper with a dry friction plate includes an installation box 5 that is used to be installed on the structure (under the action of wind load or earthquake load) and vibrates with the structure, and is covered on the inner wall of the installation box 5 buffer material 4, the dry friction plate 3 spread on the inner bottom surface of the installation box 5, the mass block 1 placed on the dry friction plate 3 in the installation box 5, and the two ends are respectively connected with the inner top of the installation box 5 and the top of the mass block 1 The equal stiffness spring 2 arranged vertically; the mass block 1 frictionally slides with the dry friction plate 3 when it moves horizontally; Will collide with the cushioning material 4.

[0019] In the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com