Tooth embedding type electromagnetic clutch

An electromagnetic clutch and tooth claw technology, applied in the clutch field, can solve the problems of insufficient suction force, inability to separate, damage, etc., and achieve the effects of lightening load conditions, convenient operation, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Traditional clutches include pressure plate assembly, driven plate, diaphragm spring, release bearing, rocker arm and resistance mechanism, etc., which involve many parts, heavy weight, many failure points, and inconvenient maintenance.

[0028] In order to solve the problem of insufficient suction force of the existing clutch or friction between the fixed armature and the movable armature, the present invention uses the accurate positioning between the movable armature and the end cover to keep the gap between the two armatures within a preset range after the clutch is separated. Ensure that the clutch has sufficient suction force when the clutch is engaged to achieve rapid engagement.

[0029] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

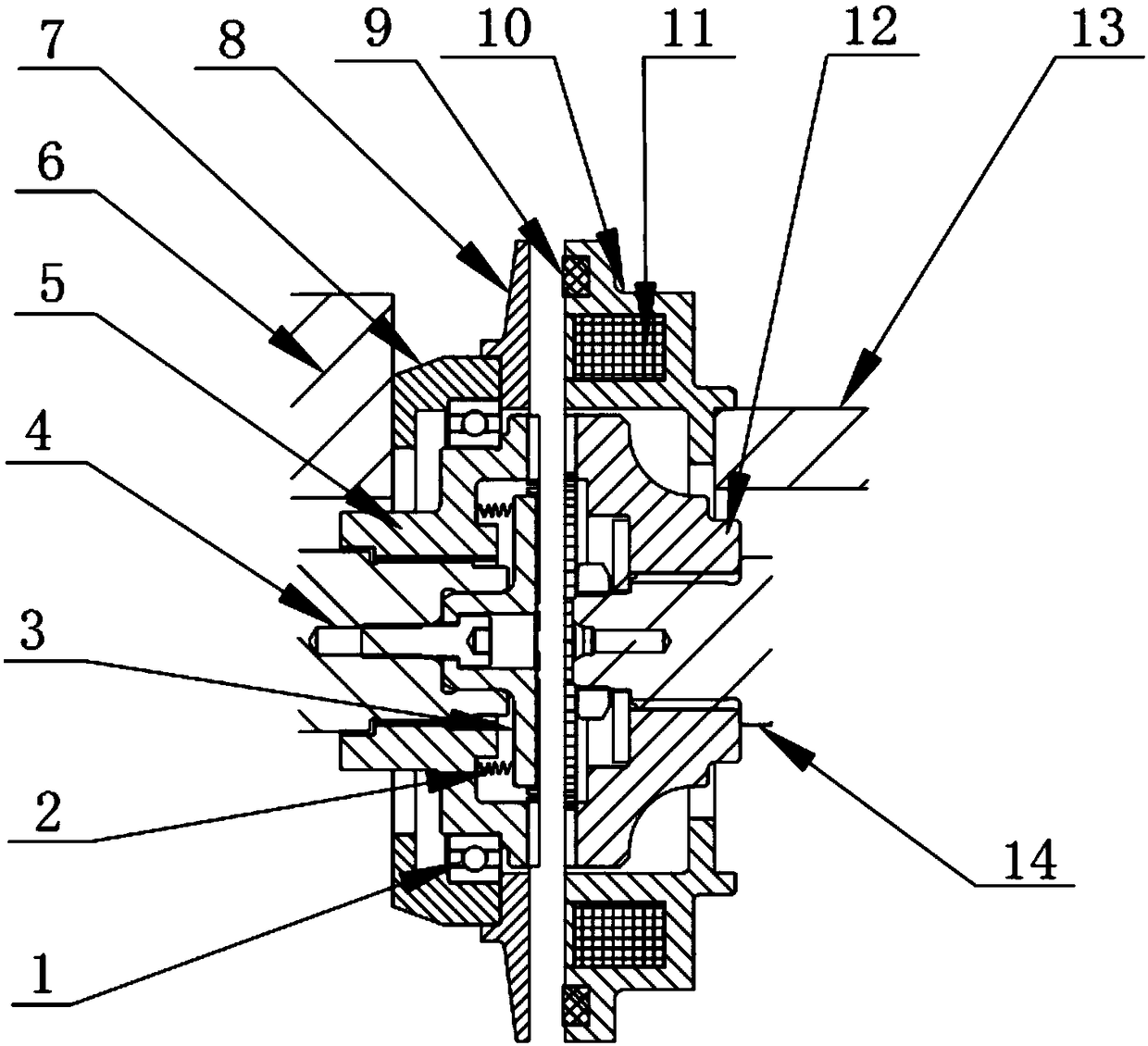

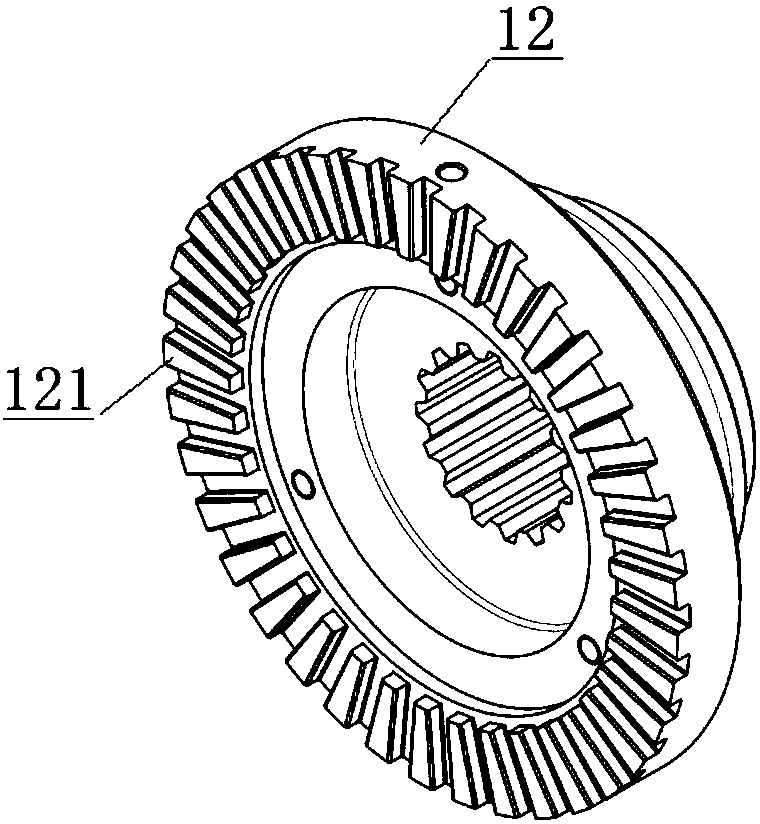

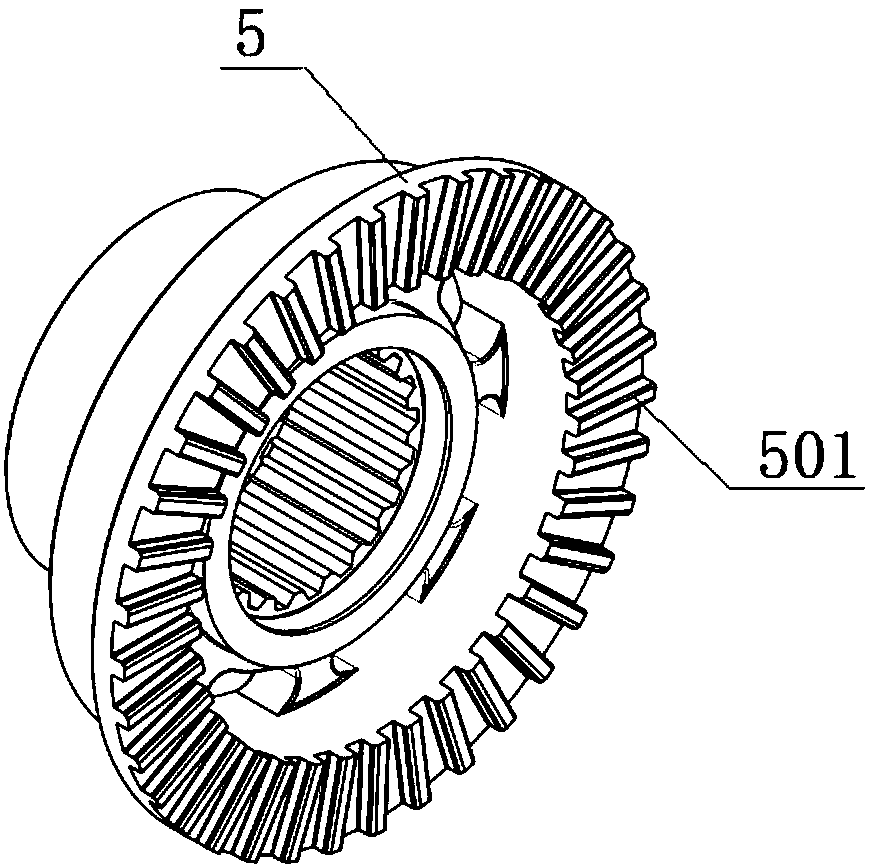

[0030] Such as figure 1 As shown, a tooth embedded elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com