Visual test device for liquid drop collision high-temperature wall surface and heating system thereof

A technology of high-temperature wall surface and droplet collision, which is used in measurement devices, engine testing, machine/structural component testing, etc. to achieve effective acquisition, small heat loss, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

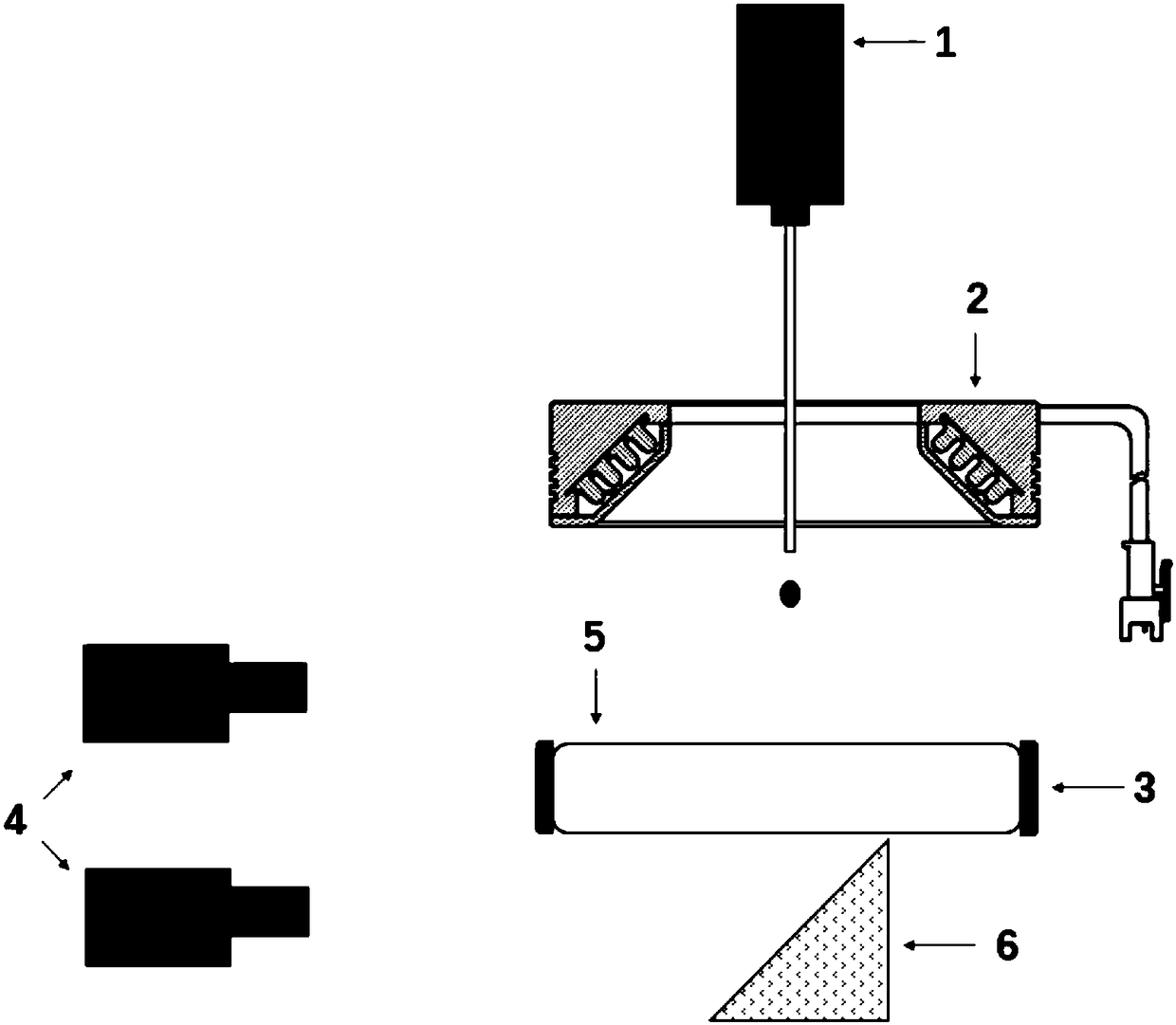

[0021] Firstly, the present invention provides a visual test device with a glass wall heating device for droplet impact on a high-temperature wall. The visual test device includes: a droplet injection system, a glass wall, a heating system and a visualization system.

[0022] Such as figure 1 As shown, the droplet injection system is a droplet injector, which is set above the glass wall, and its height can be adjusted to control the falling height of the droplet and thus the velocity of the droplet hitting the wall.

[0023] The heating system includes a heating controller and a heat source, wherein the heat source is an annular heating heat source, which is in contact with the glass wall, and the area of the glass wall surrounded by the annular heating heat source is the droplet collision experiment area. Due to the ring shape, one can make The glass wall is even...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap