ACF automatic attachment device

A sticking and automatic technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems such as the inability to provide guarantee for the lamination accuracy of the back-end FPC, hidden dangers of operation safety, non-compliance, etc., so as to avoid the attachment of defective products, The effect of improving the degree of automation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

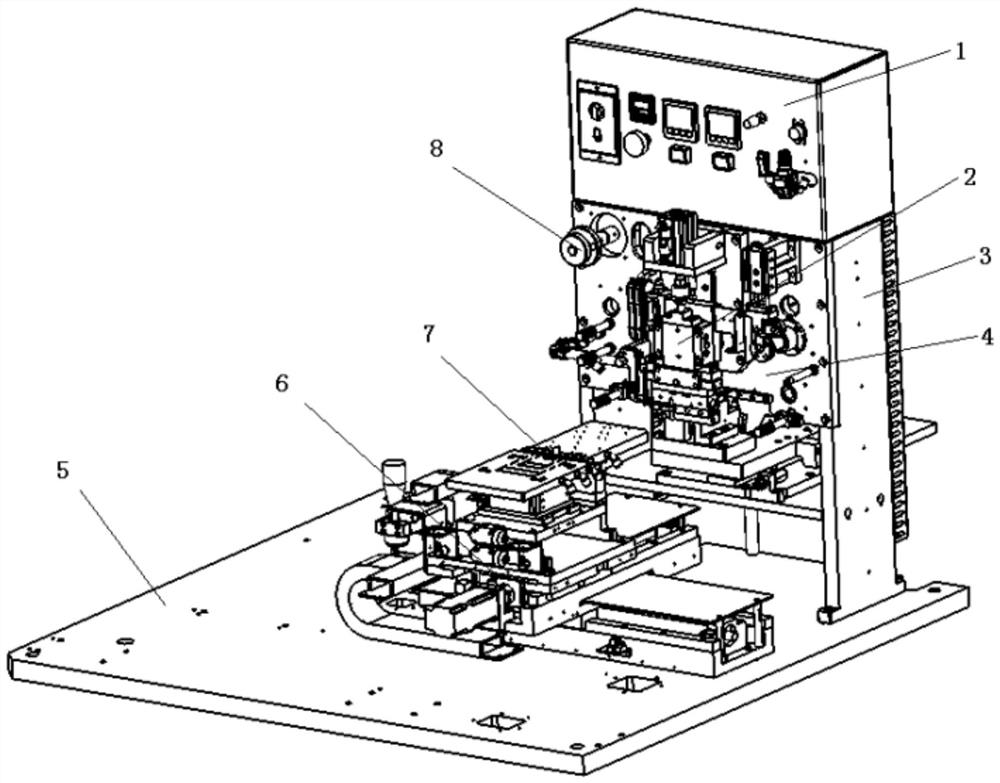

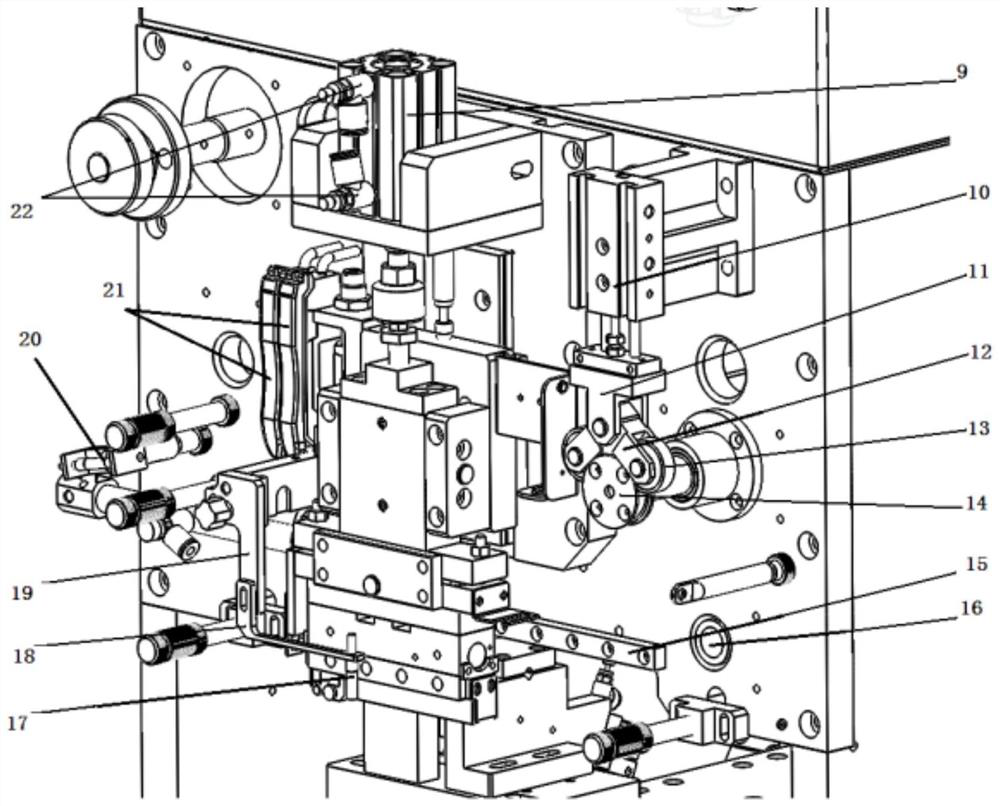

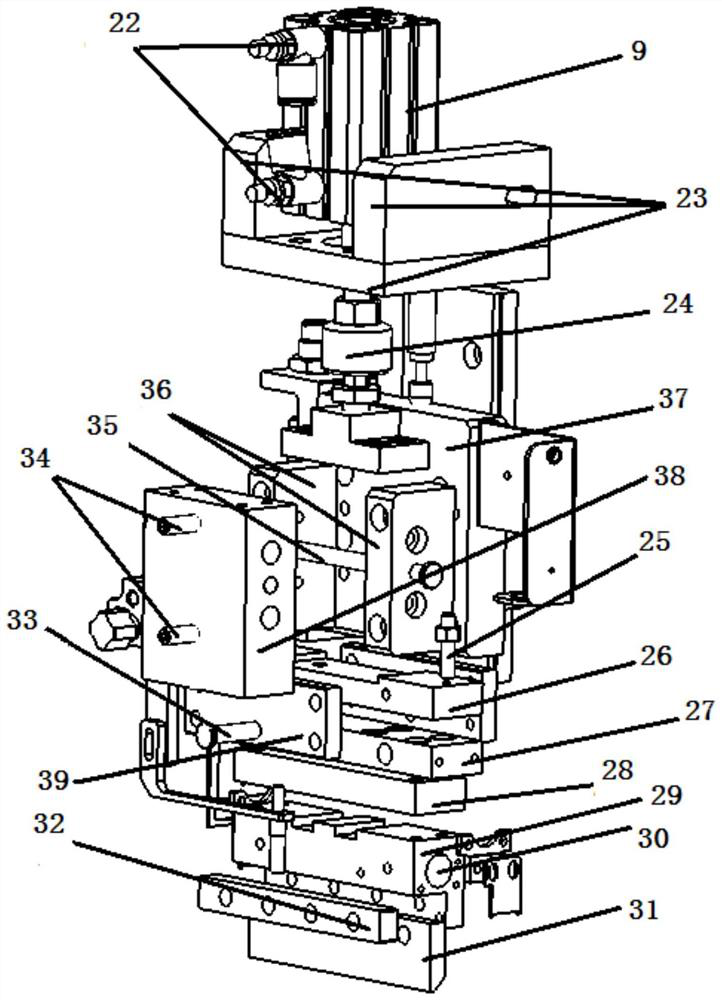

[0032] see Figure 1 to Figure 10 , the ACF automatic attachment device of this embodiment includes a fixed plate 5, a vertical plate 3 and a back plate 4, and also includes a digital display panel 1, an ACF fixed wheel 8, a waste recovery port 16, a vacuum suction device 70, and a material detection optical fiber 20 , Photoelectric controller 21, X, Y servo mechanism 6, pressure head mechanism 2, ACF attachment length detection mechanism, ACF strip automatic layering mechanism, ACF automatic length-fixing mechanism and ACF automatic cutting mechanism.

[0033] The fixed plate 5 in this embodiment is used to configure the X, Y servo mechanism 6 and provide support for the vertical plate 3. The vertical plate 3 is arranged in two and vertically connected with the fixed plate 5. The back plate 4 is arranged on the two vertical plates 3 Between, and perpendicular to vertical plate 3 and fixed plate 5, the digital display panel 1 is set on the back plate 4 and the top of vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com