Full-automatic rope cutter

A fully automatic, driving mechanism technology, applied in the field of rope cutting, can solve the problems of poor rope cutting effect and low degree of automation, and achieve good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

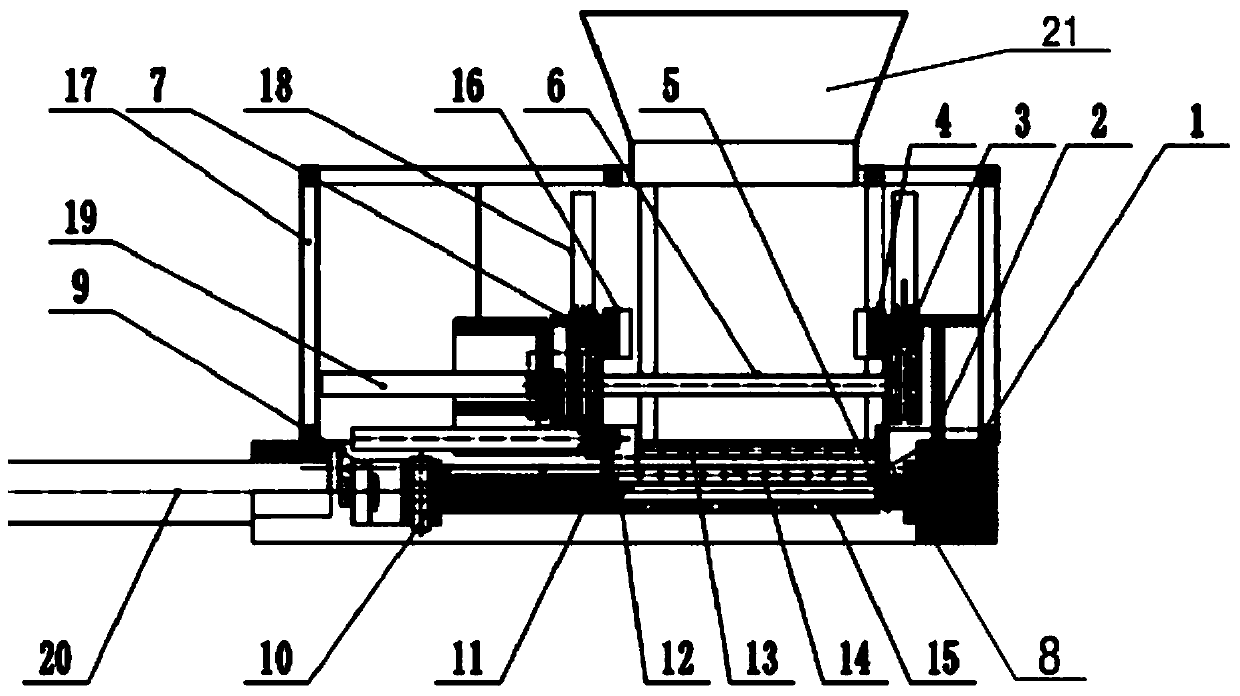

Embodiment 1

[0019] A fully automatic rope cutting machine, including a host and a control system, the host includes a bracket 1, a driving mechanism, a rope clamping mechanism, and a rope cutting mechanism, and the driving mechanism includes a driving device one 18, a driving device two 19, and a driving device three 20. Specifically, the driving mechanism is driven by hydraulic pressure. The first driving device includes 4 hydraulic cylinders, the second driving device includes 4 hydraulic cylinders, and the third driving device includes 2 hydraulic cylinders, and is equipped with a hydraulic station.

[0020] The rope clamping mechanism includes an upper chuck and a lower chuck, and the upper chuck is connected to the first driving device, and can move up and down reciprocatingly under the driving of the first driving device.

[0021] Described upper chuck comprises left movable chuck 16 and right movable chuck 4, and described left movable chuck and right movable chuck are all connected...

Embodiment 2

[0032] The other technical solutions are the same as those in Embodiment 1, except that the opposite surfaces of the left movable chuck 16 and the right movable chuck 4 are provided with a plurality of cylindrical protrusions. By adopting this technical solution, the twisted rope can be better clamped and fixed, and the twisted rope may be mixed with steel bars, strings, plastics and other substances, and the cylindrical protrusion can be inserted into the twisted rope to play a good fixing role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com