Low-temperature auxiliary heating apparatus for power battery based on phase change heat storage

A power battery, phase change technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as affecting battery life, increasing internal resistance, and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

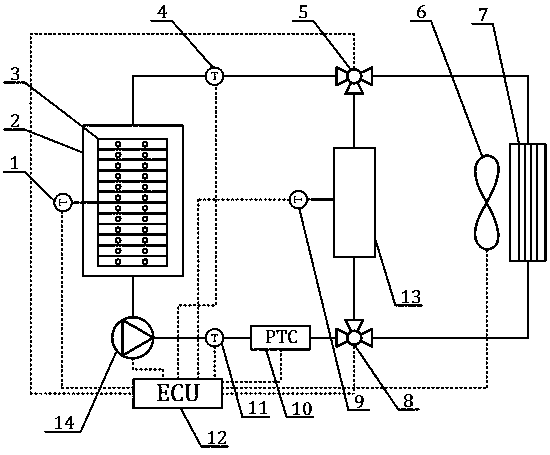

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

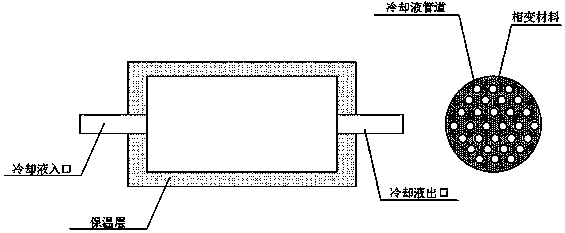

[0026] The phase-change heat storage device 13 adopted in the present invention is a single-channel heat storage device, and its structure is referred to in the appendix figure 2 , including phase change materials, coolant flow pipes, shells and insulation layers. The phase change heat storage device is a shell-and-tube heat exchanger structure, wherein the tube side is used as a coolant flow pipe, and the shell side is filled with phase change materials. The casing is provided with a cooling liquid inlet and a cooling liquid outlet, and the cooling liquid inlet and the cooling liquid outlet are connected through a cooling liquid flow pipe. The cooling fluid flow pipe is made of metal material with high thermal conductivity. Both the casing and the coolant flow pipe have certain elasticity, which can meet the stress generated by the volume change of the phase change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com