Stator Coil Insulation Integrated Method

A stator coil and coil body technology, applied in the direction of laying solid insulation, shape/style/structure of winding insulation, shape/style/structure of winding conductor, etc., can solve the problem of increasing motor power and torque, motor short-circuit fault, motor Insulation aging and other issues can be achieved to increase the input current, high power and torque, and shorten the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

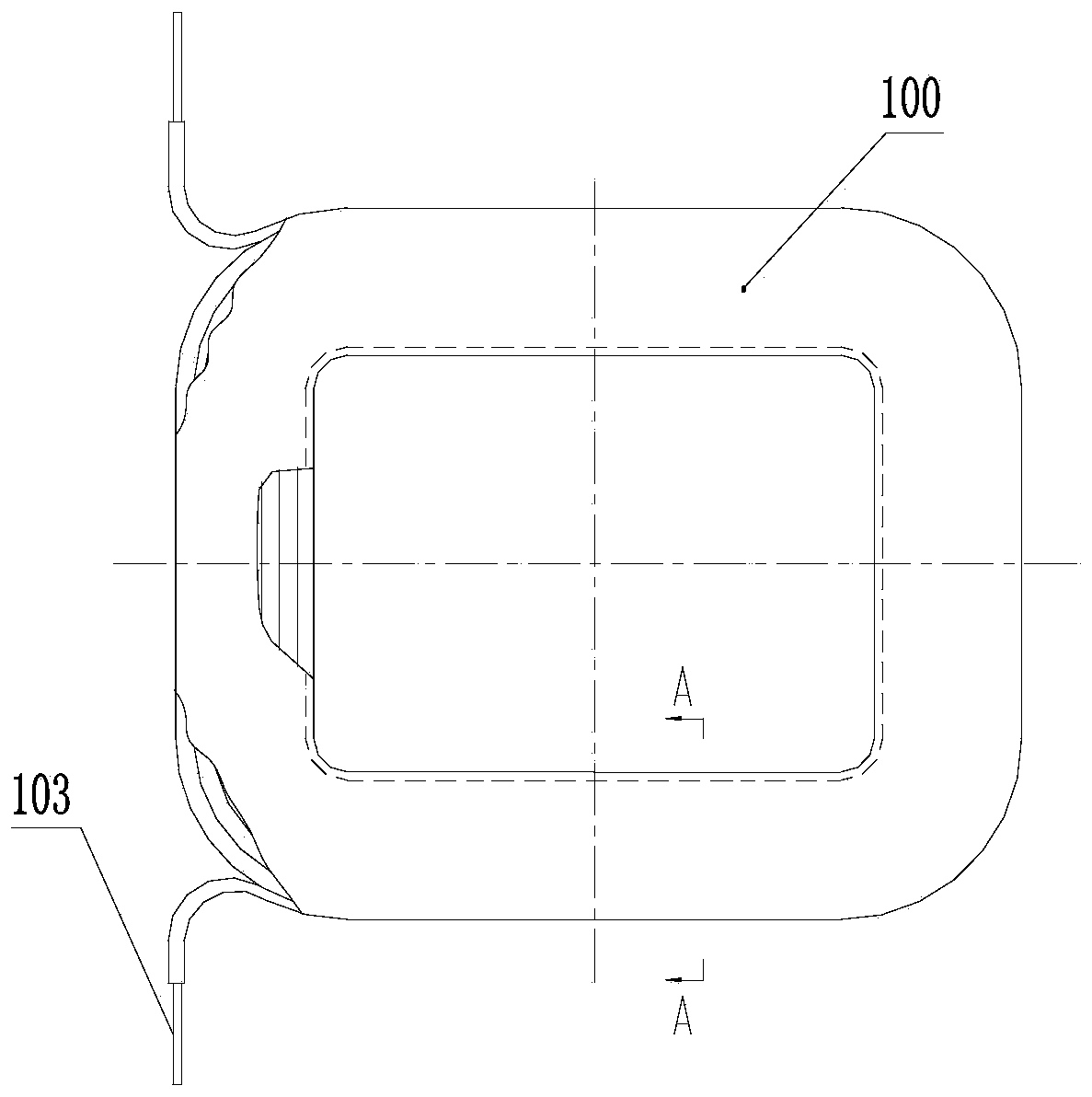

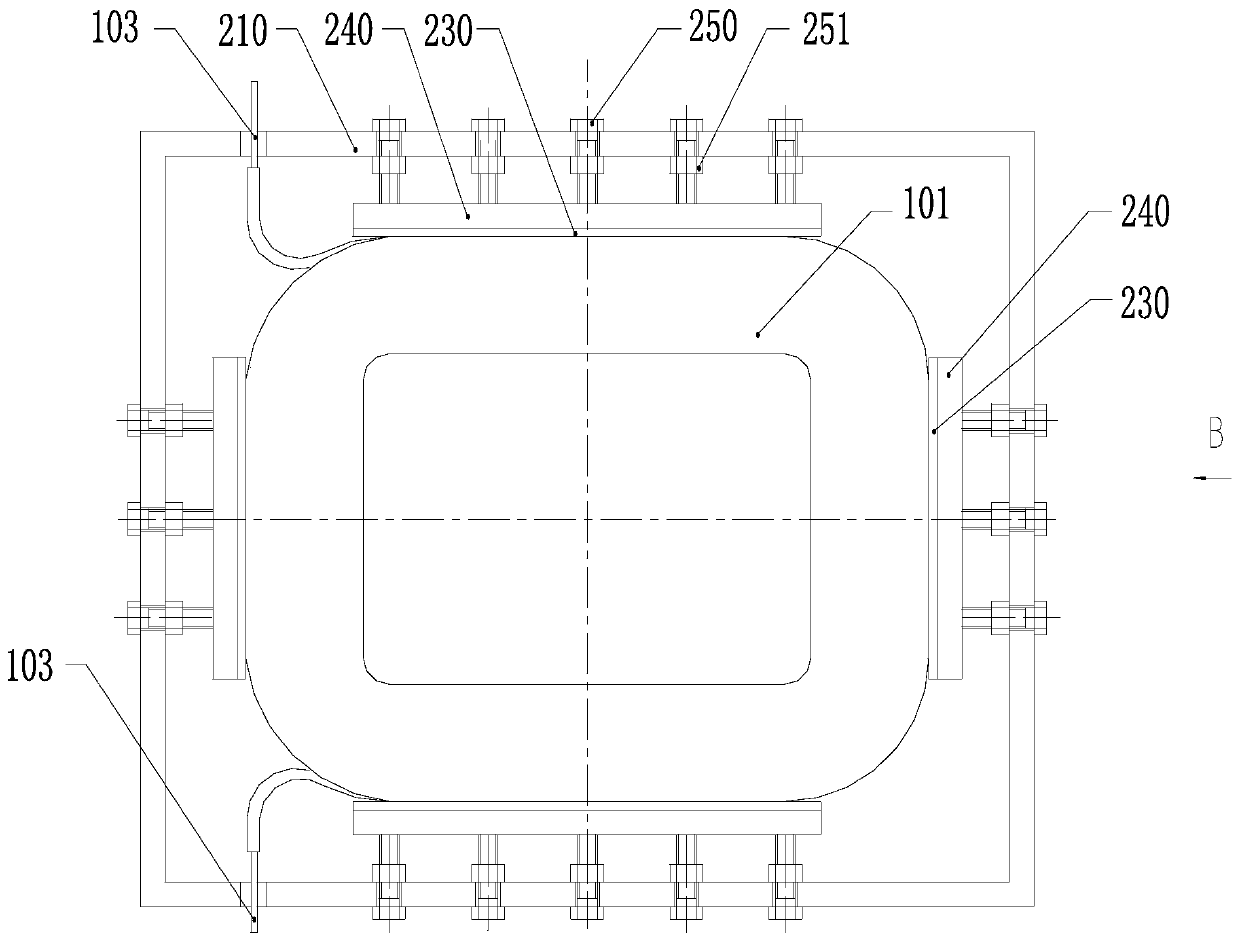

[0049] Please refer to figure 1 and figure 2 , the present embodiment provides a stator coil 100 of a DC motor, including:

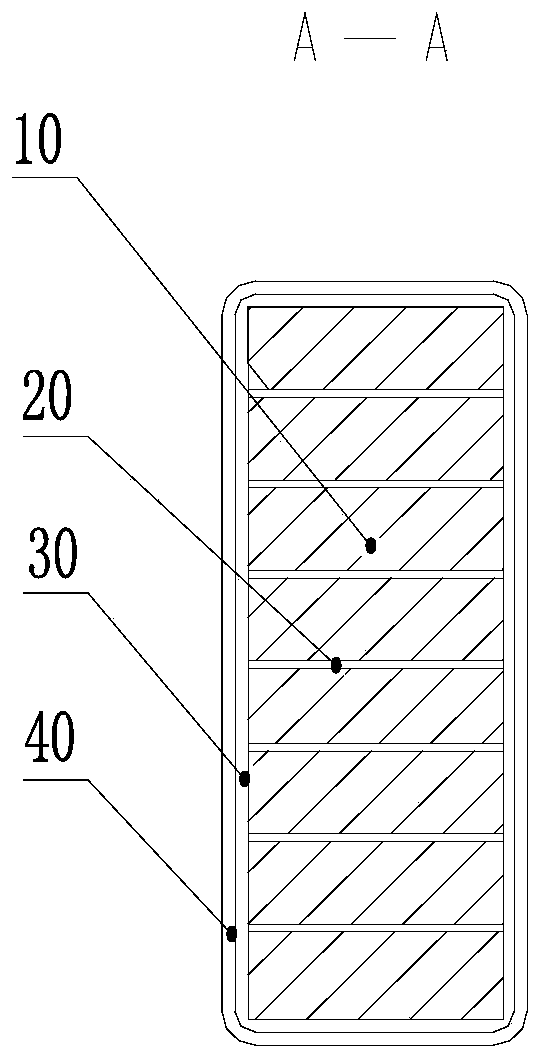

[0050] The bus bar 10 has a plurality of turns, and the multi-turn bus bar 10 is configured as a coil shape of a stator coil 100 of a DC motor;

[0051] Insulating paper tape 20, insulating paper tape 20 is placed between two adjacent turns of bus bars 10;

[0052] Silicone rubber insulating tape 30 , the outside of the multi-turn bus bar 10 is wrapped with silicon rubber insulating tape 30 .

[0053] in, figure 1The stator coil 100 of the DC motor in is actually wrapped completely, and the vacancy on the left is to show the busbar 10 therein. It should not be understood that the actual finished product is also this style. figure 1 with figure 2 The film heat shrinkable tape in the figure just means the coating during processing, and the actual finished product does not have this layer structure.

[0054] Wherein, the busbar 10 used in this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com