Method of realizing double-sided component welding on single-sided printed circuit board (PCB)

A technology of components and components, which is applied in the field of circuit welding, can solve problems such as increased hardware costs, and achieve the effect of reducing hardware costs and strong earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

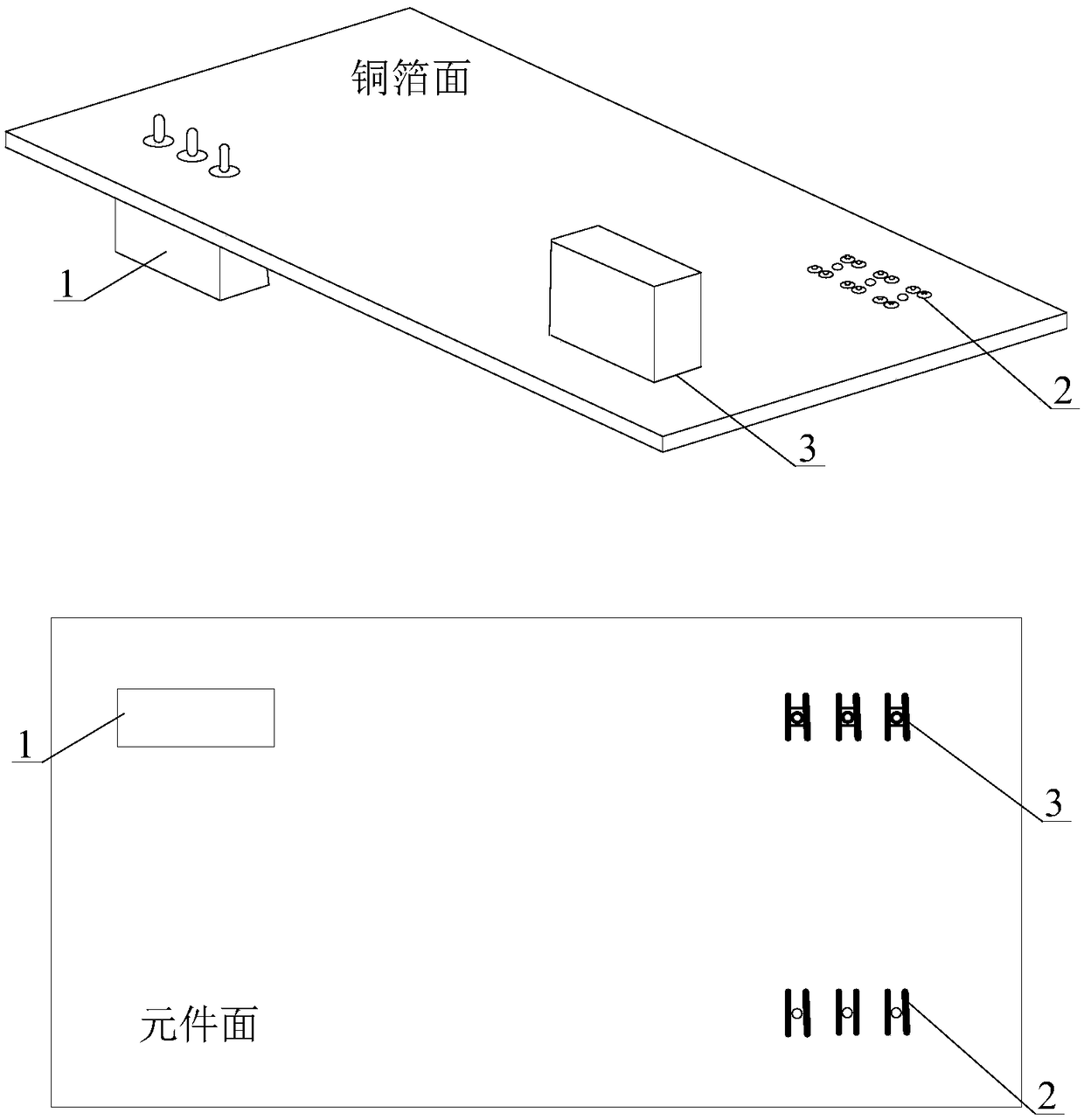

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

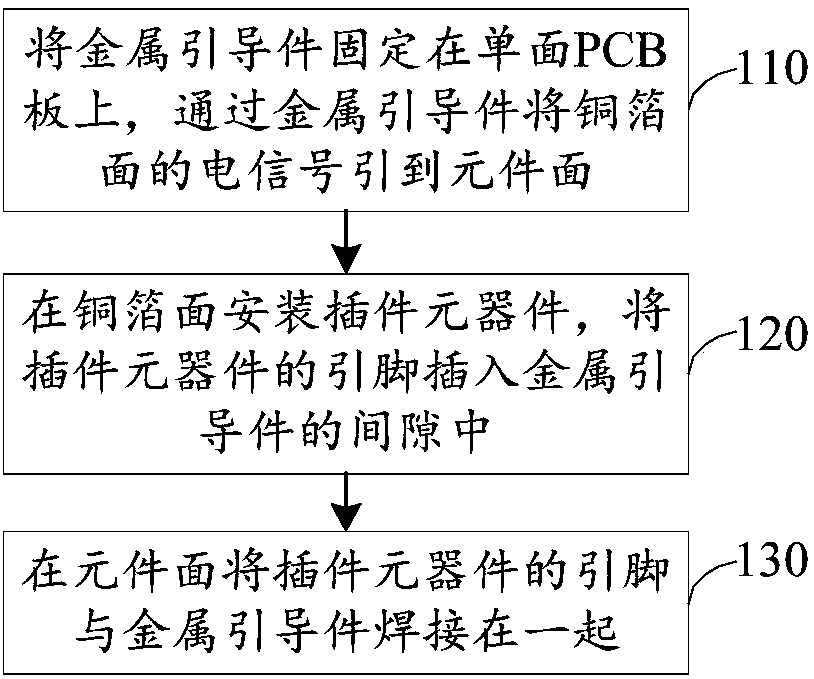

[0032] figure 1 It is a flow chart of a method for realizing double-sided soldering components on a single-sided printed circuit board provided by an embodiment of the present invention, such as figure 1 As shown, the method may include:

[0033] Step 110, fixing the metal guide on the single-sided PCB, and leading the electrical signal on the copper foil surface to the element surface through the metal guide.

[0034] The metal guide is made of metal, and the signal layer is changed through the metal guide, and the electrical signal on the copper foil surface is guided to the component surface.

[0035] Step 120, install the plug-in components on the copper foil surface, and insert the pins of the plug-in components into the gaps of the metal guides.

[0036] Step 130, soldering the pins of the plug-in component and the metal guides toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com