Smear detection device, laser via processing device, and laser via processing method

A detection device, laser drilling technology, applied to measuring devices, fluorescence/phosphorescence, laser welding equipment, etc., can solve the problem that visual inspection takes a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

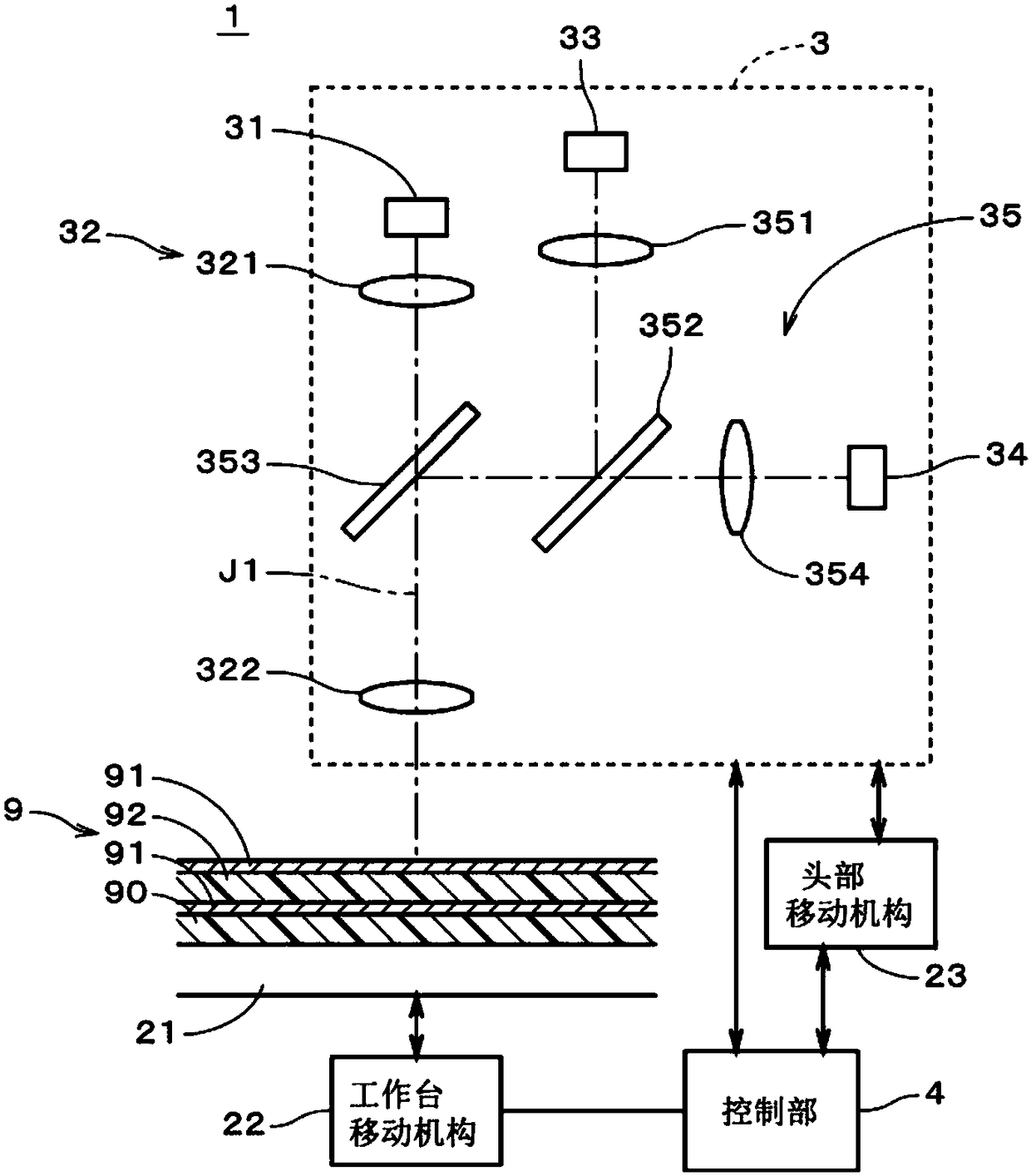

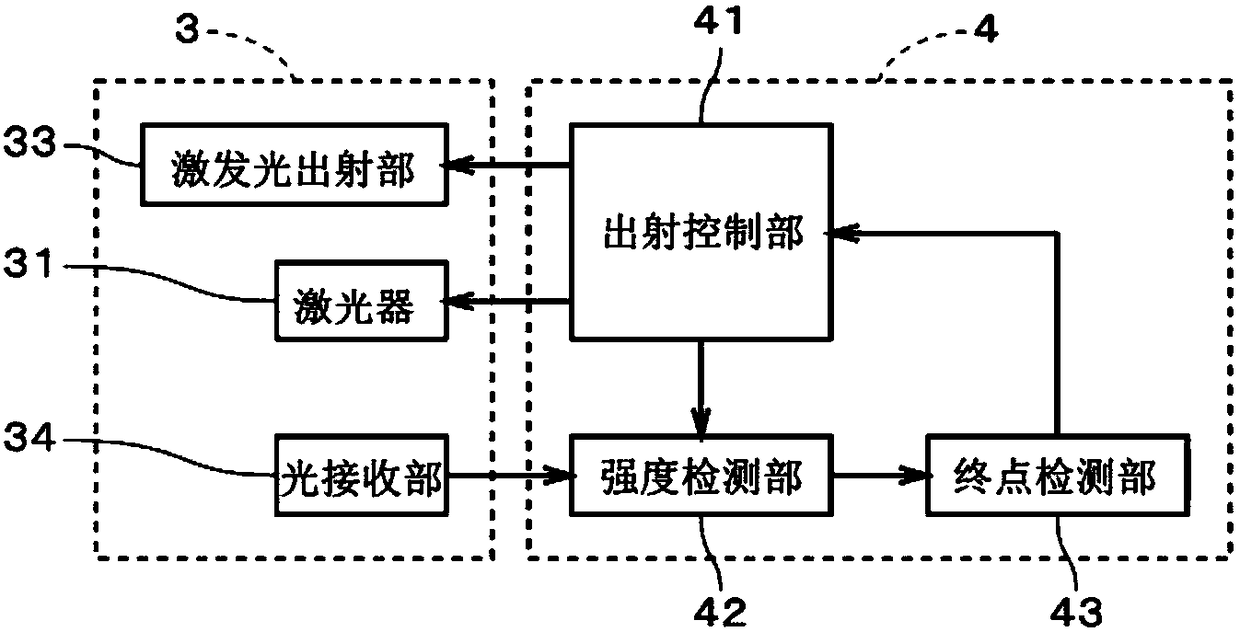

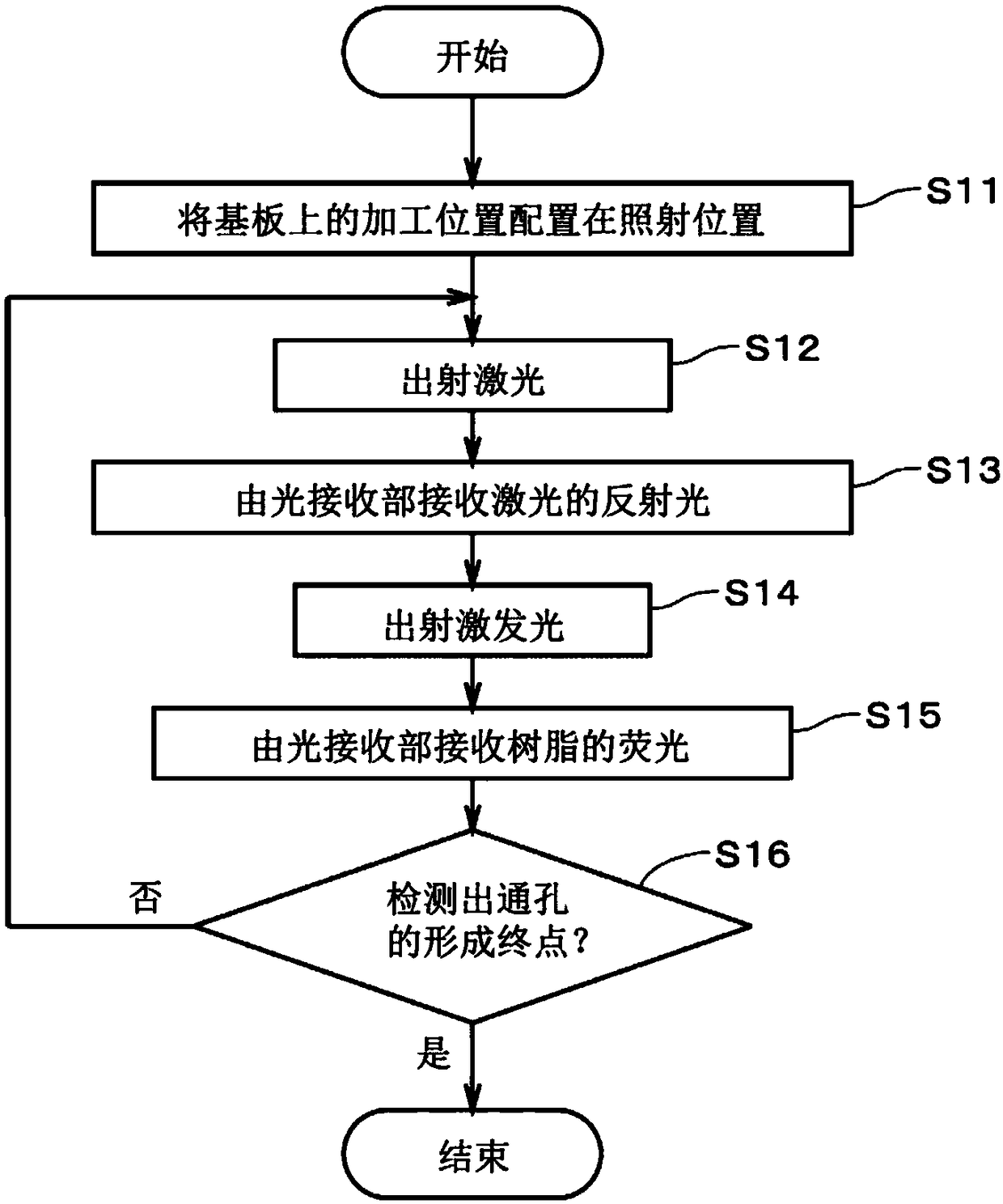

[0023] figure 1 It is a figure which shows the structure of the laser drilling processing apparatus 1 which concerns on one Embodiment of this invention. The laser drilling processing device 1 is used for laser drilling processing when manufacturing the multilayer substrate 9 , that is, using a laser to form through holes on the multilayer substrate 9 in the manufacturing process. The laser drilling process is a part of the connection process in the manufacture of the multilayer substrate 9 . In the multilayer substrate 9 , for example, wiring layers 91 and insulating layers 92 are alternately laminated on a plate-shaped or thin-plate-shaped base material 90 formed of resin. The wiring layer 91 is a wiring pattern formed of a conductive material such as copper. The insulating layer 92 is formed of a resin such as polyimide, and insulates adjacent wiring layers 91 . In the following description, the multilayer substrate 9 in the process of manufacture is simply referred to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com