A vertical sewage processor with self-cleaning function

A sewage treatment and self-cleaning technology, which is applied in fixed filter element filters, chemical instruments and methods, separation methods, etc., can solve the problems of inconvenient sediment cleaning, high infrastructure cost, large floor space, etc., and can prolong the water flow. Walking path, avoiding gas pollution, and realizing the effect of full utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

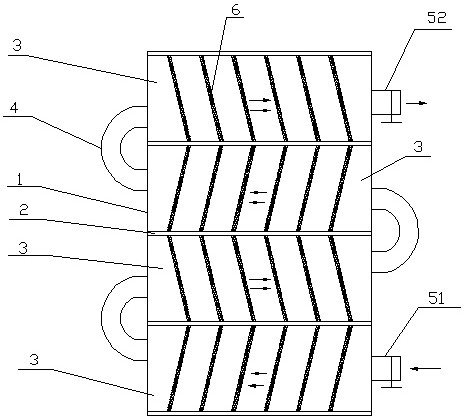

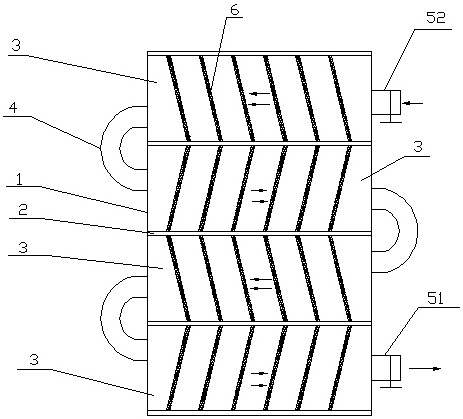

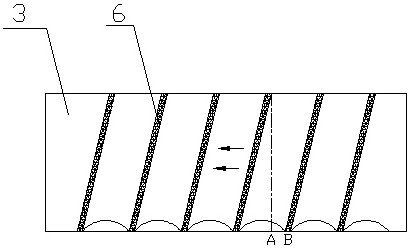

[0033] Such as Figure 1 to Figure 4 As shown, a kind of vertical sewage processor with self-cleaning function of the present invention includes a vertically arranged treatment tower 1, and a plurality of horizontal partitions 2 are arranged at intervals from bottom to top in the treatment tower, each horizontal partition 2 are sealed and fixedly connected with the processing tower 1, so that the cavity in the tower is divided into a plurality of processing chambers 3 arranged up and down; in this embodiment, there are four processing chambers 3. Adjacent processing chambers 3 are connected by communication pipes 4 to form a serpentine walking path, wherein a water inlet 51 is arranged on the lowermost processing chamber, and a water outlet 52 is arranged on the uppermost processing chamber. It is equipped with a water inlet sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com