Automatic rust removing device for petroleum pipe fittings

A pipe fitting and automatic technology, which is applied in the direction of grinding/polishing safety devices, grinding workpiece supports, grinding machines, etc., can solve the problems of high operating intensity, high time cost, and harsh construction environment for construction personnel, so as to reduce labor intensity, The effect of improving work efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

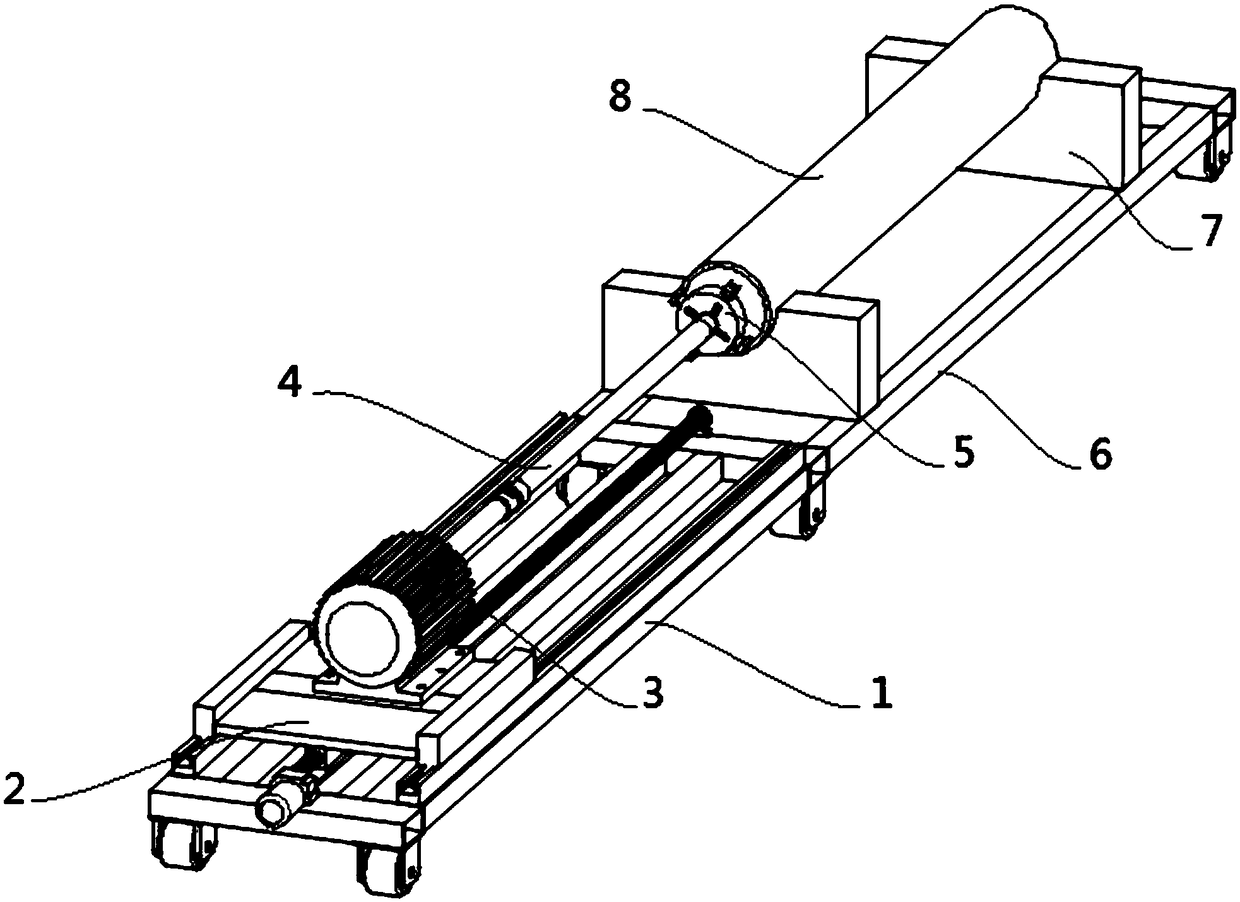

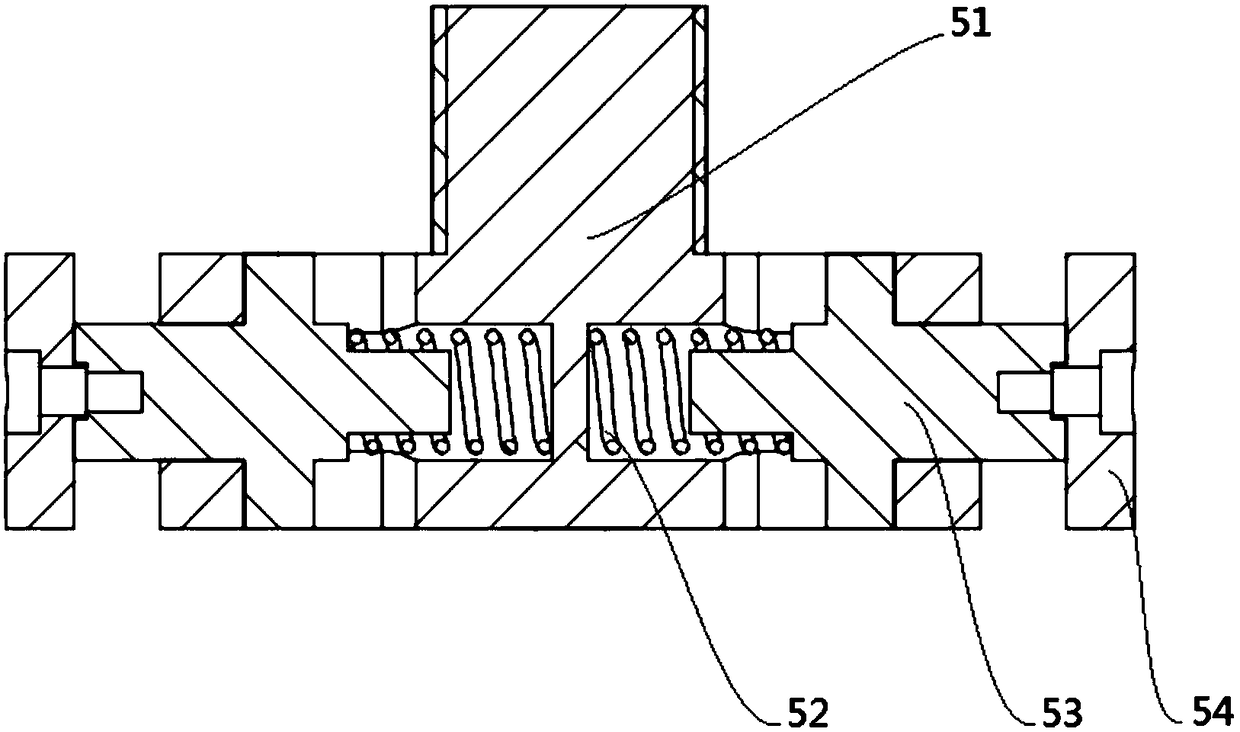

[0021] Such as figure 1 and figure 2 As shown, an automatic derusting device for petroleum pipe fittings of the present invention includes a base 1, a sliding table 2, a motor 3, a transmission shaft 4, and a grinding assembly 5. The upper part of the base 1 is installed with a sliding table 2 through a guide rail, and the sliding table 2 The length direction of the seat 1 moves linearly, and the motor 3 is fixedly installed on the slide table 2. The rotor output shaft of the motor 3 is connected to one end of the transmission shaft 4, and the other end of the transmission shaft 4 is connected to the grinding assembly 5. The grinding assembly 5 includes a rotating disk 51 , There are four grinding sheets 54 arranged on the outer circle of the rotating disk 51 , and the four polishing sheets are evenly distributed along the outer circle of the rotating disk 51 . There are four blind holes evenly distributed on the outer circumference of the rotating disk 51, the depth directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com