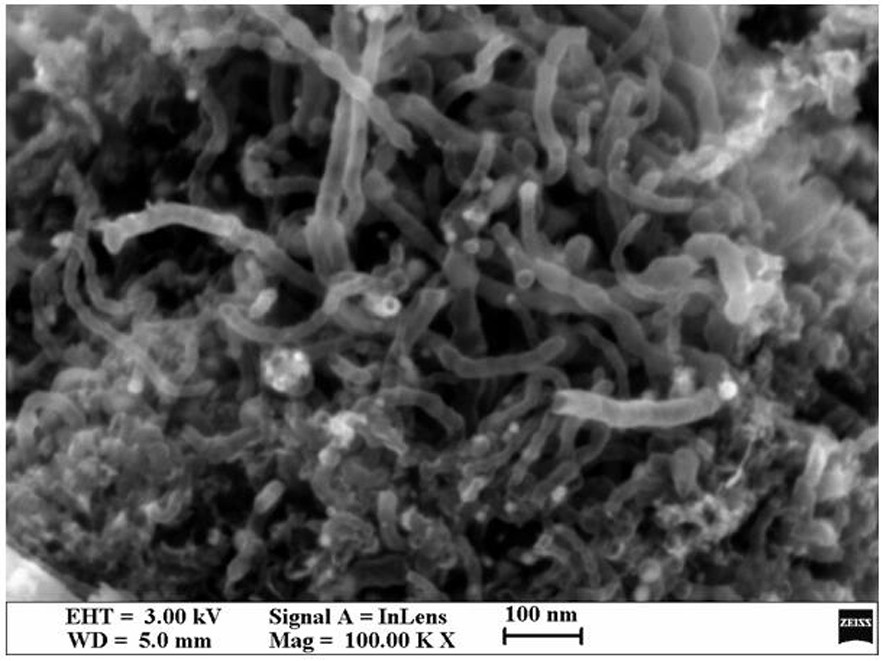

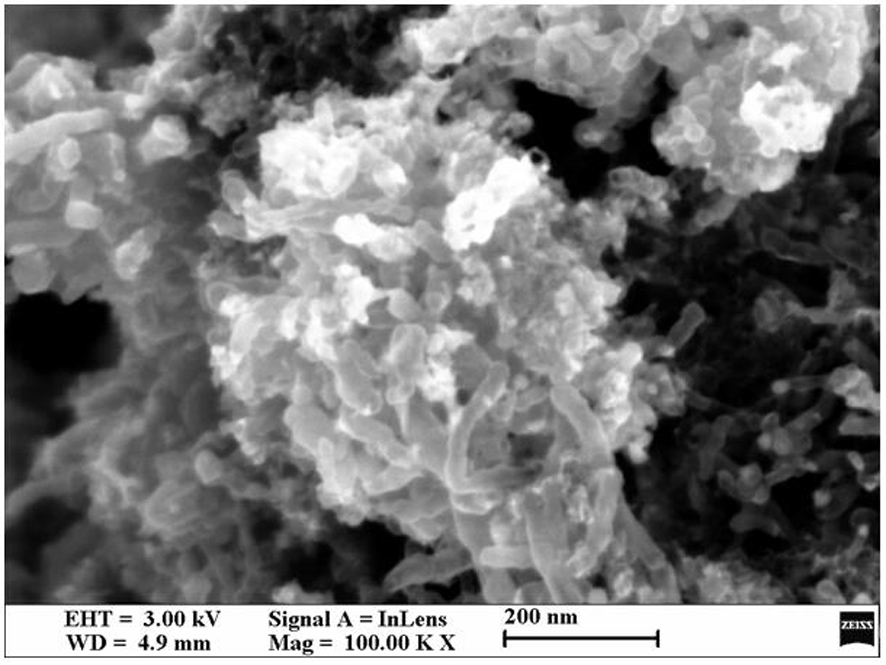

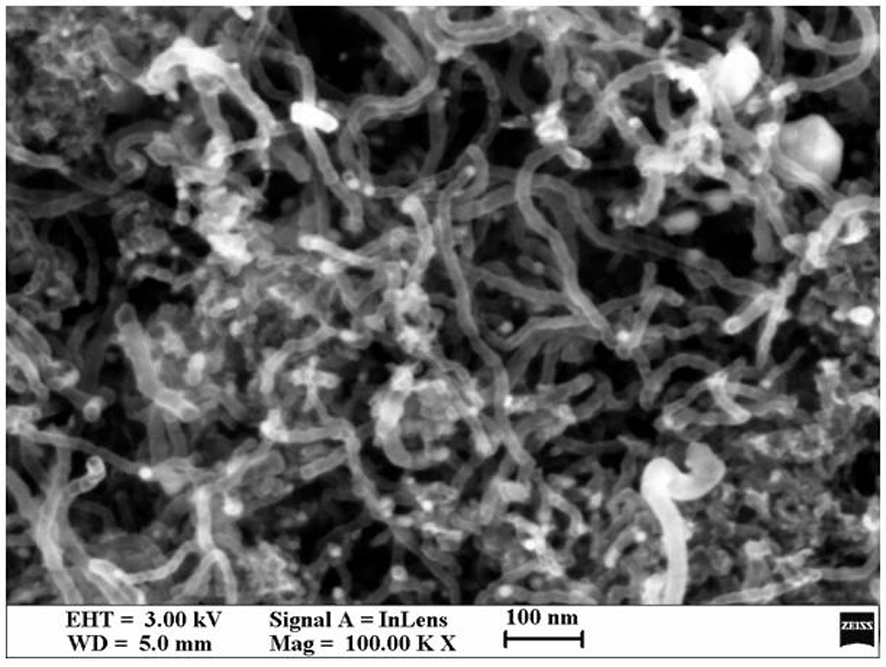

Preparation method of nitrogen-doped porous carbon/carbon nanotube composite with interpenetrating network structure

A technology of interpenetrating network structure and carbon nanotubes is applied in the field of preparation of nitrogen-doped porous carbon/carbon nanotube composites to achieve the effects of high production efficiency, high specific surface area and rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a nitrogen-doped porous carbon / carbon nanotube composite with an interpenetrating network structure, comprising the steps of:

[0034] 1) Preparation of fluffy graphitized porous carbon

[0035] Weigh and mix the emulsified pitch and aluminum ethoxide according to the mass ratio of 1:2, then add n-butanol twice the weight of the mixture to the mixture, mix the two evenly by mechanical stirring, and pass nitrogen gas, the stirring temperature is 100°C , stirring time is 1h. After stirring evenly, the solvent was distilled off under reduced pressure and placed in a vacuum oven (1.0×10 -1 Pa) Dry for 6h and cool to room temperature. Place the dried sample in an atmosphere furnace, feed nitrogen, raise the temperature to 800°C at 5°C / min, keep it for 1h, then raise the temperature to 1100°C at 3°C / min, keep it for 2h, cool to room temperature and take it out for use.

[0036] 2) Preparation of nitrogen-doped carbon nanotubes

[0037] Take by weigh...

Embodiment 2

[0040] A method for preparing a nitrogen-doped porous carbon / carbon nanotube composite with an interpenetrating network structure, comprising the steps of:

[0041]1) Preparation of fluffy graphitized porous carbon

[0042] Weigh and mix petroleum asphalt and aluminum lactate according to the mass ratio of 1:1, then add dichloromethane 3 times the weight of the mixture to the mixture, mix the two evenly by mechanical stirring, and pass nitrogen gas, the stirring temperature is 80°C , Stirring time is 1.5h. After stirring evenly, the solvent was distilled off under reduced pressure, placed in a vacuum oven (1.0×10-1Pa) at 50°C for 12 hours, and cooled to room temperature. Place the dried sample in an atmosphere furnace, pass in argon, raise the temperature to 900°C at 5°C / min, keep it warm for 2h, cool to room temperature and take it out for use.

[0043] 2) Preparation of nitrogen-doped carbon nanotubes

[0044] Take by weighing 0.1g fluffy graphitized porous carbon, add ul...

Embodiment 3

[0047] A method for preparing a nitrogen-doped porous carbon / carbon nanotube composite with an interpenetrating network structure, comprising the steps of:

[0048] 1) Preparation of fluffy graphitized porous carbon

[0049] Weigh and mix coal tar pitch and zinc chloride according to the mass ratio of 1:3, then add ethanol 4 times the weight of the mixture to the mixture, mix the two evenly by mechanical stirring, and pass nitrogen gas, the stirring temperature is 110 ° C, Stirring time is 2h. After stirring evenly, the solvent was distilled off under reduced pressure and placed in a vacuum oven (1.0×10 -1 Pa) Dry for 10h and cool to room temperature. The dried samples were placed in an atmosphere furnace, fed with nitrogen, heated to 700°C at a rate of 4°C / min, kept for 3h, cooled to room temperature and taken out for later use.

[0050] 2) Preparation of nitrogen-doped carbon nanotubes

[0051] Weigh 0.1g of fluffy graphitized porous carbon, add 5% ethanol aqueous soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com