Open type single-net double-flow slurry inclined net forming machine

An open type, former technology, applied in textile and papermaking, paper machine, wet end of paper machine, etc., can solve the problems of sedimentation, flocculation and large-scale turbulence, affecting the longitudinal and lateral distribution of fibers and paper performance, to prevent The effect of settlement, low cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

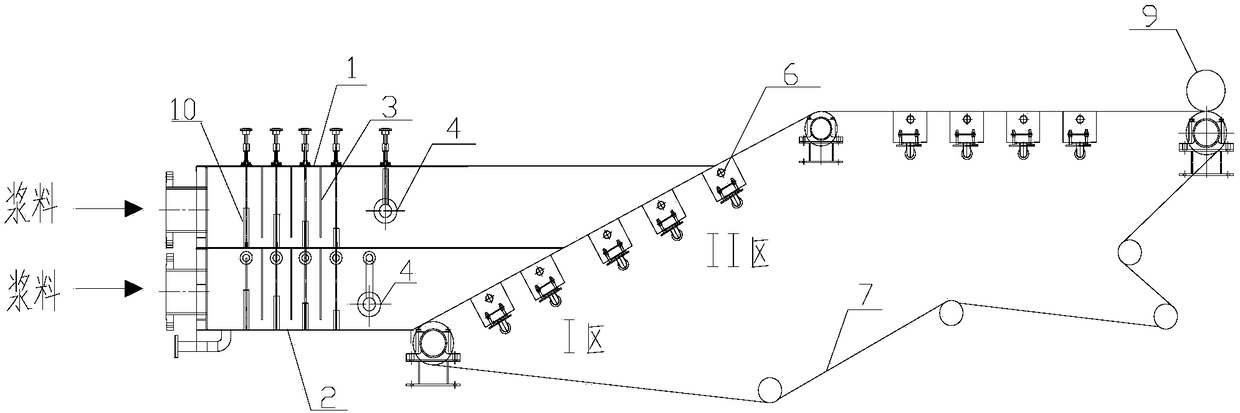

[0032] Such as Figure 1-3 As shown, an open single-wire double-flow slurry inclined wire former includes two headboxes and a ring-shaped forming wire 7 wound on multiple driving rollers. The inclined section of the forming wire 7 is along the moving direction of the forming wire Divided into zone Ⅰ and zone Ⅱ, two headboxes are set up and down, the pulp outlet of the upper headbox 1 is overlapped with the upper part of the forming wire in zone Ⅱ; the pulp outlet of the lower headbox 2 is connected with the forming wire in zone Ⅰ Overlapping of the upper surface;

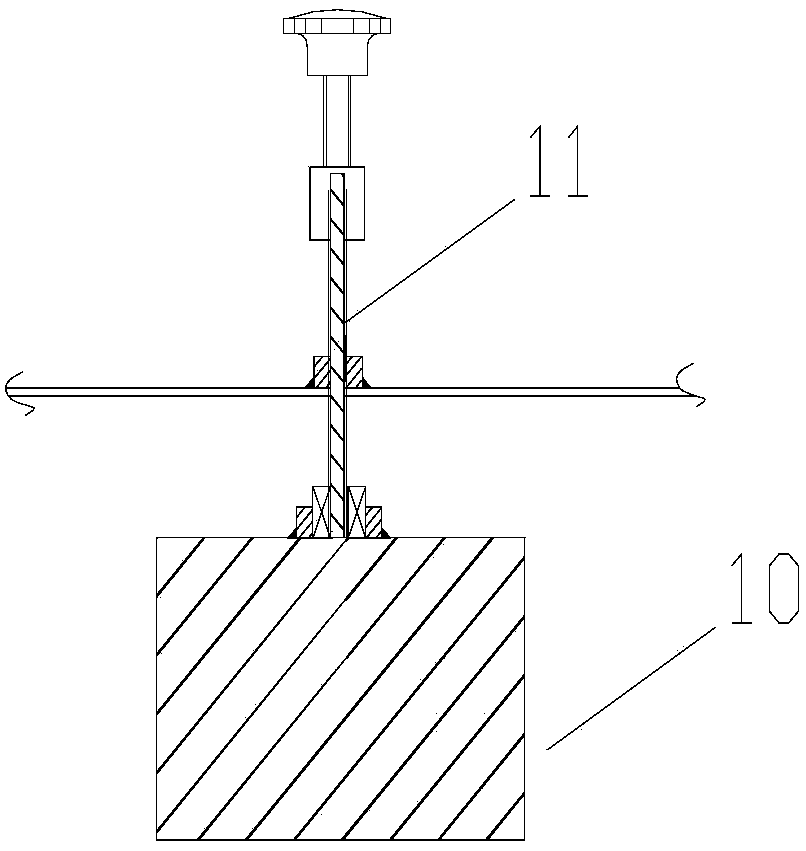

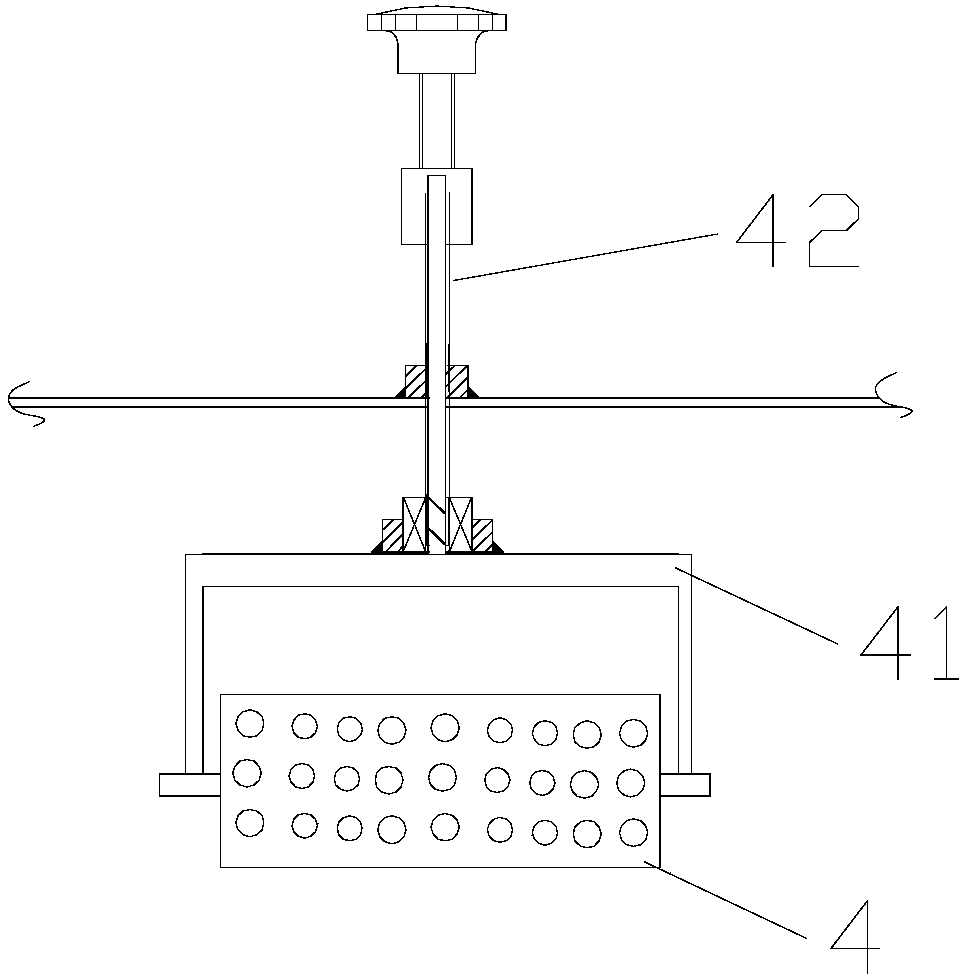

[0033] A plurality of baffles are arranged in the two headboxes, and the plurality of baffles in each headbox are divided into two groups, including an upper baffle group and a lower baffle group, wherein the upper baffle group includes multiple The upper partitions 3 with the same height and equidistant arrangement, the upper end and both sides of the upper partition 3 are sealed and fixedly connected with the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com