Gas-lift oil production one-round well completion pipe string and process

A completion string and gas lift technology, applied in drill pipe, casing, production fluid, etc., can solve the problems of difficulty in salvaging the packer, failure to lose hands, waste of manpower, etc., to eliminate the risk of well retention, easy to The effect of the movement of the pipe string and the large diameter of the well retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

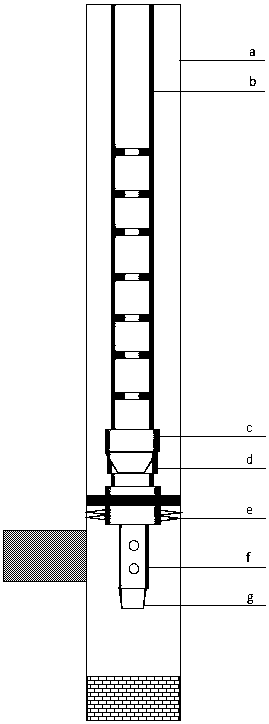

[0060] See attached Figure 1-5 , a completion string for one trip of gas lift oil production, comprising a tubing b, a running tool c, a sealing device d, a packer e, a perforated pipe f and a plug g connected sequentially from top to bottom, specifically as follows:

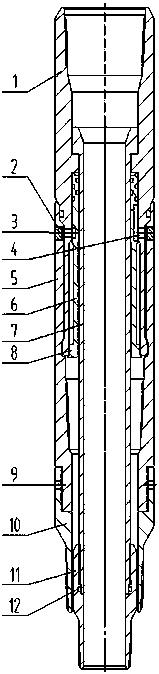

[0061] (1) Feed tool

[0062] The feeding tool includes an upper joint 1, a pin 2, a drop pin 3, a suspension pin 4, a lock sleeve 5, a first piston 6, a first ball seat 7, a support ring 8, a lower joint 10 and an inner joint 11; The upper joint 1 , the locking sleeve 5 and the lower connecting head 10 are sequentially connected from top to bottom to form the outer pipe part, and the first ball seat 7 and the inner connecting head 11 are connected up and down to form the inner pipe part.

[0063] The outer pipe part is specifically: the upper end of the upper joint 1 is connected with the oil pipe b through threads, the outer surface of the lower end of the upper joint 1 is provided with a boss, the inner sur...

Embodiment 2

[0075] See attached Figure 1-5 , the completion process of the gas-lift oil recovery one trip completion string in embodiment 1, comprises the steps:

[0076] 1) Lower pipe string

[0077] Bottom-up connection: plug g + perforated pipe f + packer e + sealing device d + feeding tool c + tubing b, slowly descend to the design depth.

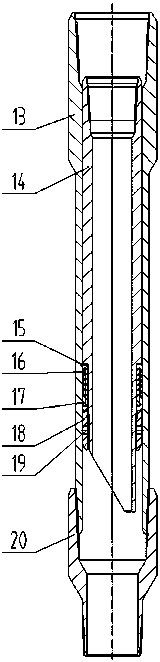

[0078] 2) Packer setting

[0079] Pump liquid into the annulus between casing a and tubing b, through the annulus between feeding tool c, sealing device d, packer e and casing a respectively, through the holes in perforated pipe f Inside it, pass through the packer e, the sealing device d, and the feeding tool c to the inner cavity of the casing b and return until the returned liquid is clean and free of oil, put in the steel ball 41, and wait for the steel ball to fall to the second ball seat 43 Up; pump liquid into the tubing b with a small displacement, the liquid pressure goes down to the sealing device d through the feeding tool c, and conti...

Embodiment 3

[0089] A well completion process for one completion string of gas lift production, the process steps are basically the same as in Example 2, when step 4) of the well completion process fails to be successfully carried out, step 5) is automatically carried out due to abnormal pressure, that is, The second ball seat 43 and the steel ball 41 have been knocked off while the feeding tool has not been lost; in this case, the second ball can be thrown through the oil pipe b, and the ball falls on the first ball seat 7 of the feeding tool. Then carry out the operation of step 4) of the completion process, that is, perform the second drop; the above-mentioned second ball throwing and then throwing can ensure the successful completion of the throwing process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com