Fuel oil jetting system of heavy oil engine and aircraft engine

A fuel injection system and fuel injection technology, applied in the direction of engine components, machines/engines, fuel injection devices, etc., can solve the problems of substandard emissions, high viscosity of heavy oil, difficulty in starting the engine, etc., to achieve full combustion, full combustion and The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

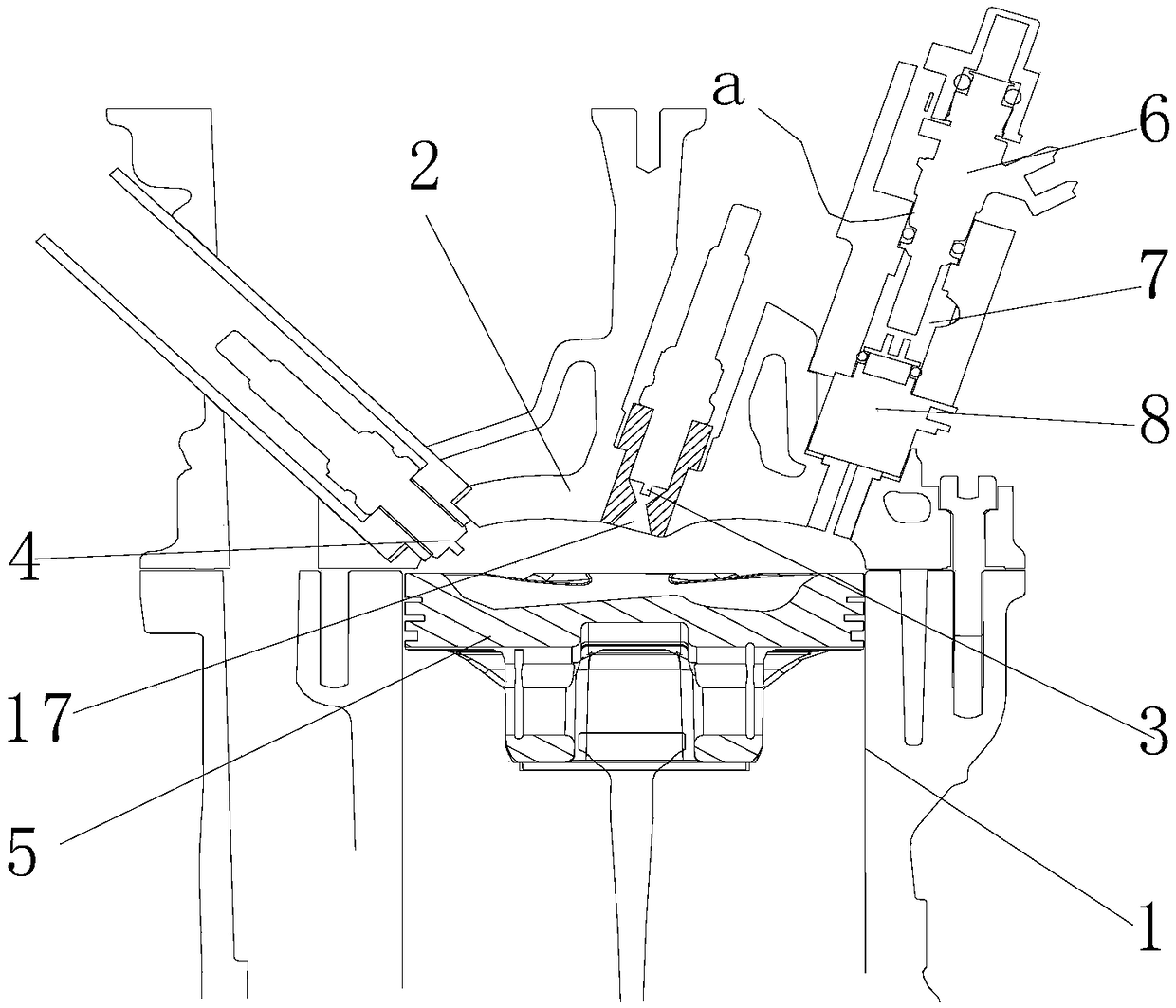

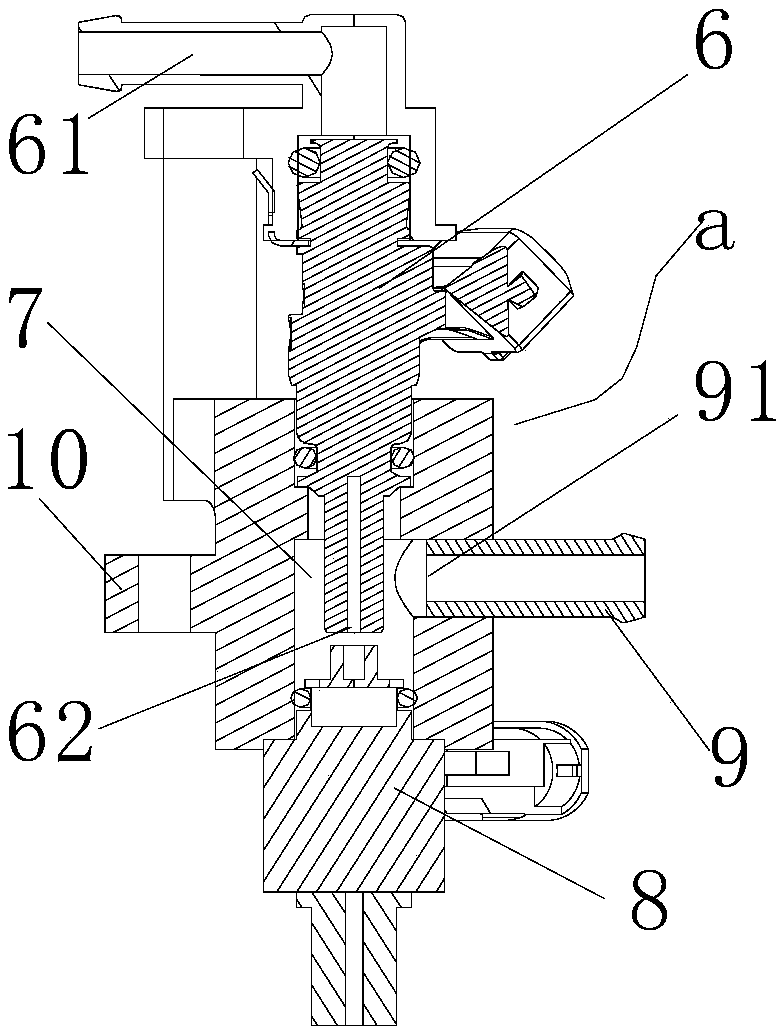

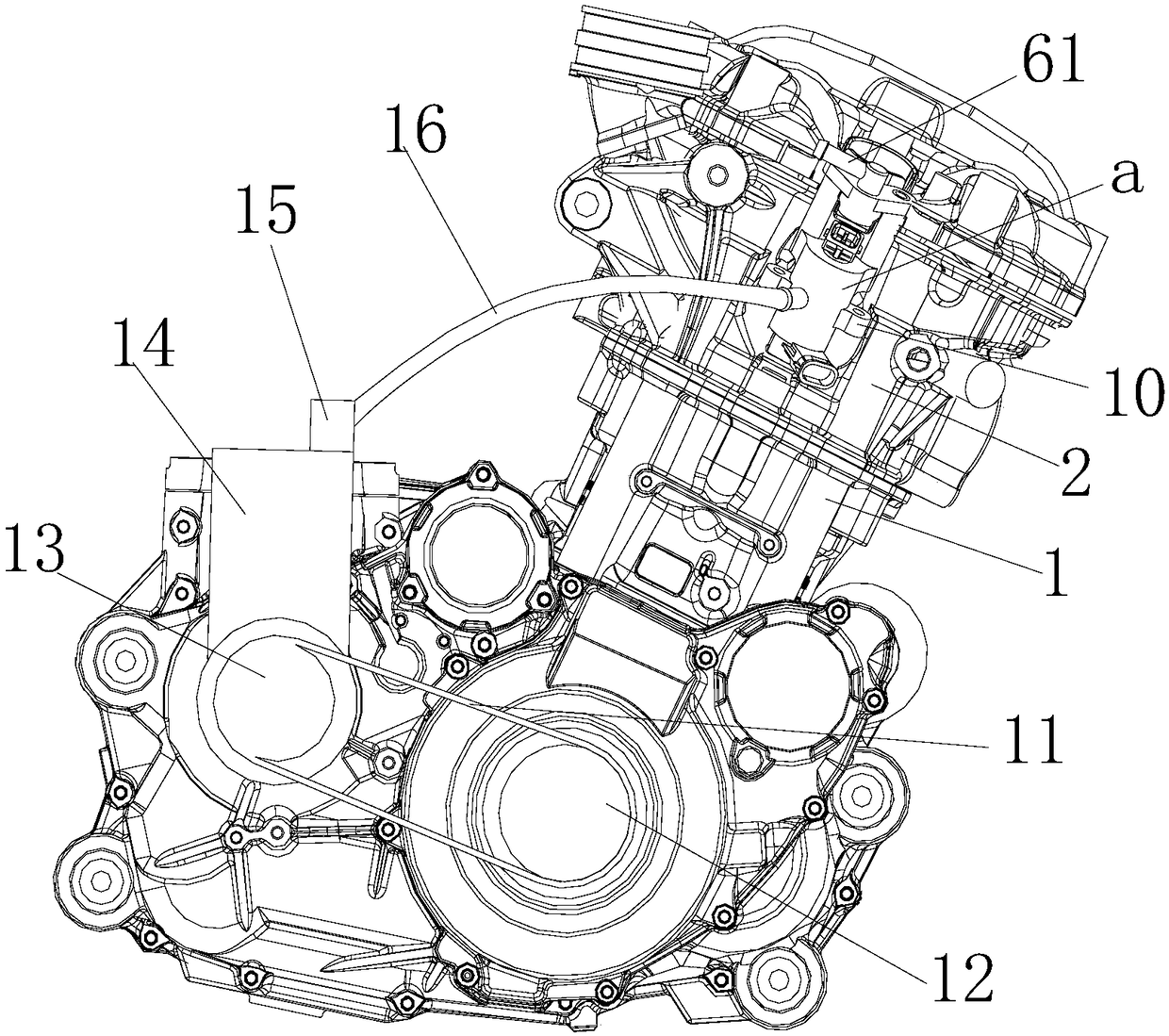

[0018] As shown in the figure: the heavy oil engine fuel injection system of this embodiment includes a compressed air system and a fuel injection assembly, and the compressed air system includes an air compressor and an air supply pipeline; the fuel injection assembly includes a fuel nozzle 6, a premixing chamber 7 and the oil-air mixing nozzle 8, the fuel injection port of the fuel nozzle 6 and the compressed air inlet (that is, the compressed air outlet of the air compression system) are arranged in the premixing chamber 7, and the oil-air mixing nozzle 8 communicates with the premixing chamber 7 The atomized mixed fuel gas formed by fuel and compressed air in the premixing chamber is sent to the combustion chamber of the engine; the auxiliary low-pressure air is used to realize premixing in the premixing chamber and further atomize the fuel sprayed by the fuel nozzle to ensure direct injection in the later stage After entering the combustion chamber, more sufficient atomiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com