A sine wave powered dual-degree-of-freedom helical motor with position self-locking function

A sine wave, degree of freedom technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of limiting the linear force and efficiency of the motor, complex motor structure, large magnetic resistance, etc., and achieve the effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

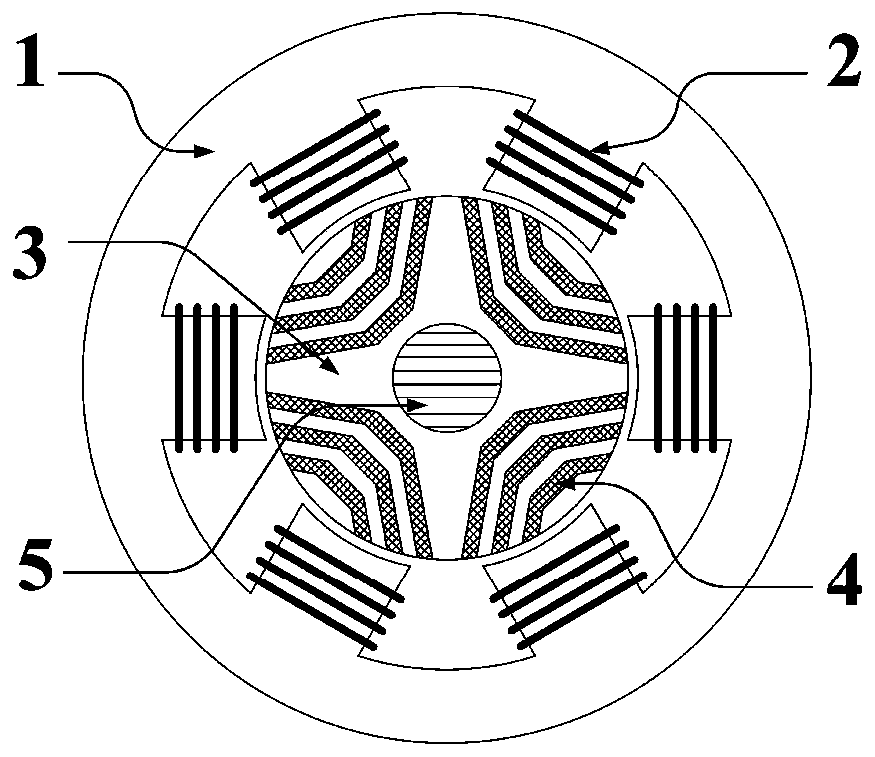

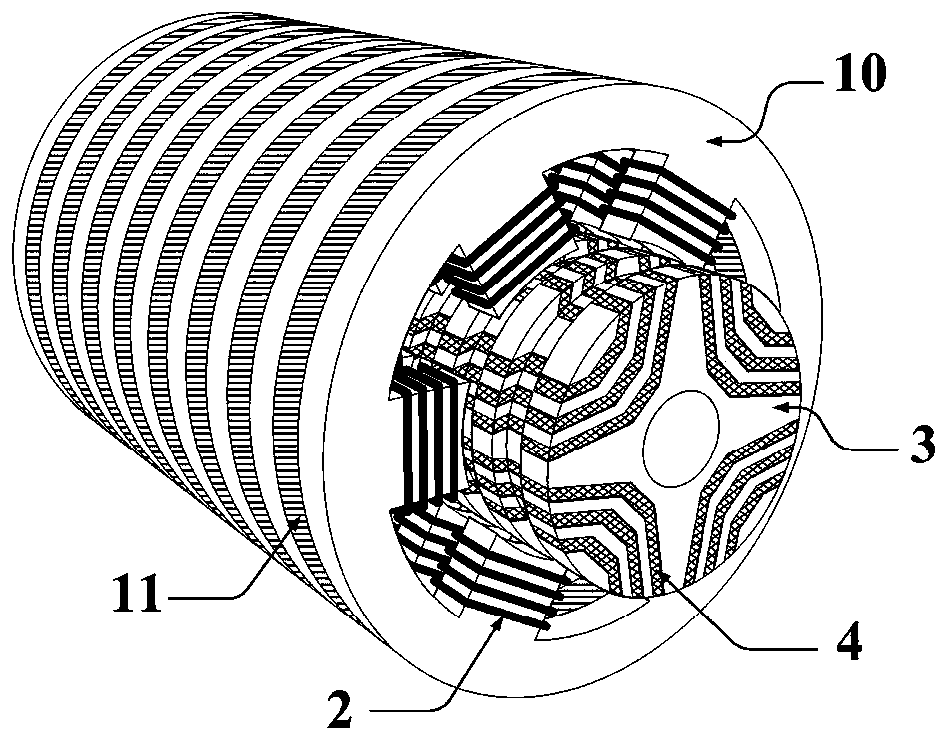

[0031] like figure 1 and figure 2 As shown, the sine wave power supply dual-degree-of-freedom spiral motor with position self-locking function of the present invention includes a stator core 1, an armature winding 2, a mover non-magnetic base 3, a mover magnetic core 4, and a rotating shaft 5; Iron core 1 is composed of stator power iron core 10 and stator annular iron core 11, and armature winding 2 is placed on stator power iron core 10; stator power iron core 10 and stator annular iron core 11 are arranged alternately and closely arranged along the axial direction; It is located on the non-magnetic base 3 of the mover; the non-magnetic base 3 of the mover, the magnetic core 4 of the mover and the rotating shaft 5 together constitute the mover.

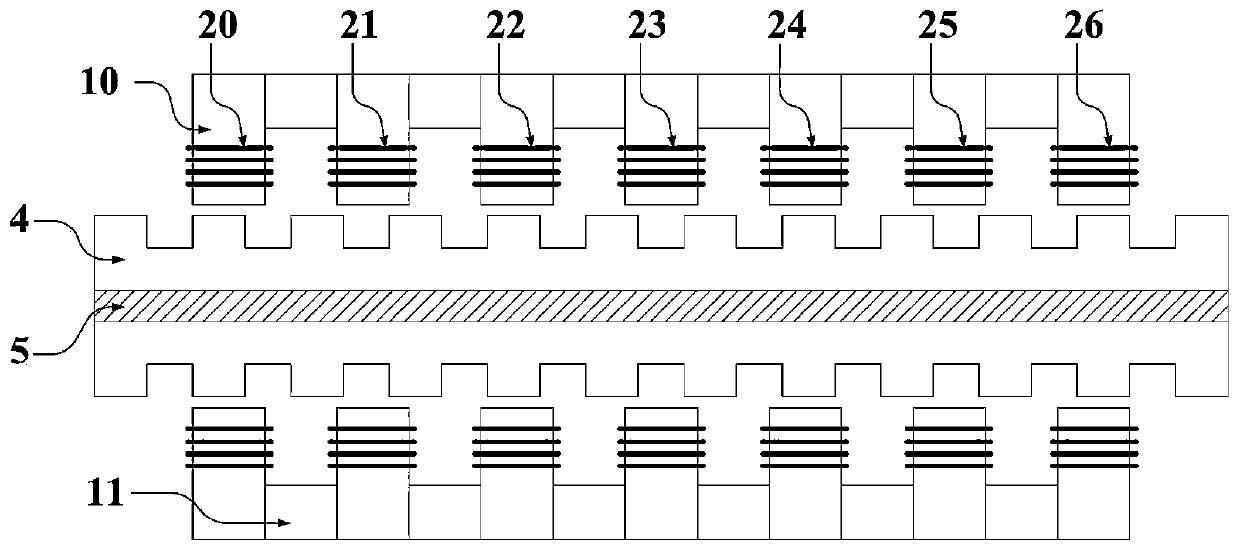

[0032] like image 3 As shown, the mover presents a salient pole structure in the axial direction; the armature windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com