High-pressure passivation air compressor set pollution discharge separation and recovery device and application method

An air compressor unit, separation and recovery technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of large labor, difficult operation by operators, and poor separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

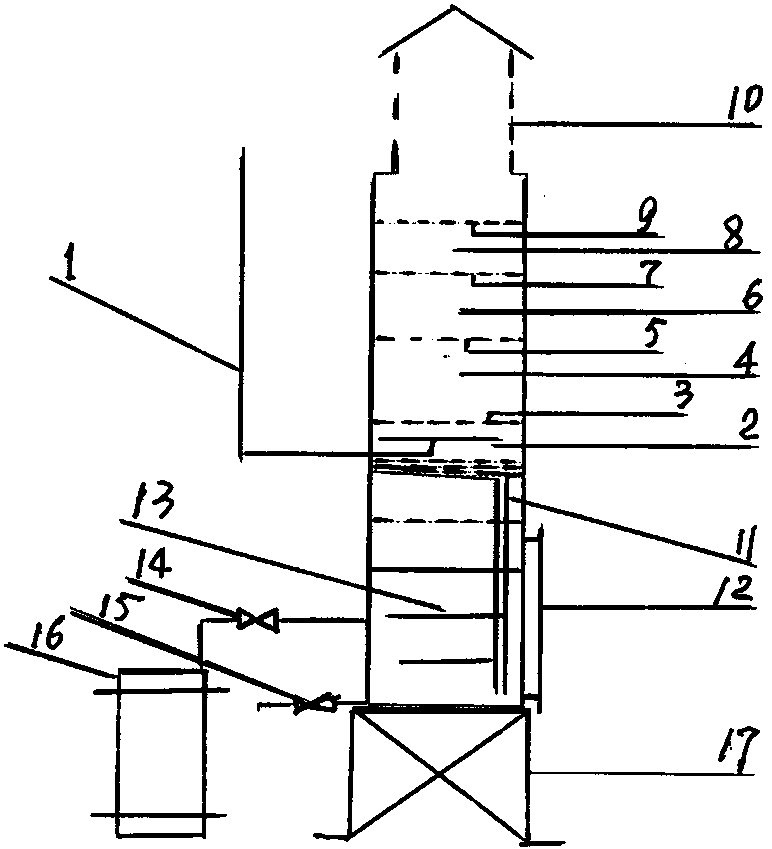

[0015] Embodiment 1. The present invention includes a gas-liquid separator, a liquid collector 11, and an oil-water separator 13. The liquid collector 11 is located below the gas-liquid separator and can separate the gas-liquid separator from the oil-water separator.

Embodiment 2

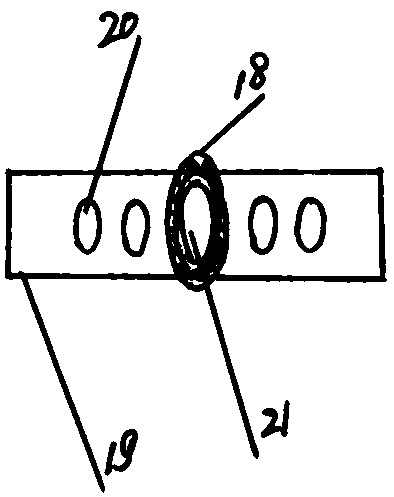

[0016] Embodiment 2. The gas-liquid separator includes an air compressor blowdown line 1, a distributor 2, a packing support block 3, a Raschig ring 4, a first packing isolation plate 5, a saddle ring 6, a second packing isolation plate 7, Pall ring 8, packing pressure plate 9, venting rain and snow proof cap 10; Raschig ring 4, saddle ring 6, Pall ring 8 are installed in the gas-liquid separator, and a venting cap is installed on the top of the gas-liquid separator. Waterproof snow-lifting cap 10; described packing supporting block 3 is positioned at the bottom of Raschig ring 4; described first packing separating plate 5 is positioned at the middle of Raschig ring 4, saddle ring 6; described second packing separating plate 7 is positioned at The middle of the saddle ring 6 and the Pall ring 8; the packing pressing plate 9 is located on the top of the Pall ring 8.

Embodiment 3

[0017] Embodiment 3, one end of the blowdown pipeline 1 of the air compressor is connected to the blowdown outlet of the compressor unit, and the other end is connected to the distributor 2, the Raschig ring 4, the saddle ring 6, the Pall ring 8, and the emptying and waterproof snow-lifting cap 10 in sequence connected in series to form a gas-liquid separator.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com