Crankshaft driven interval feeding type resin paint blending device

A crankshaft drive, resin technology, applied in transportation and packaging, mixer accessories, dissolution and other directions, can solve the problems of inability to achieve uniform mixing, poor mixing effect, slow filtration speed, etc., to improve fluidity, improve purity, Stir and mix well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

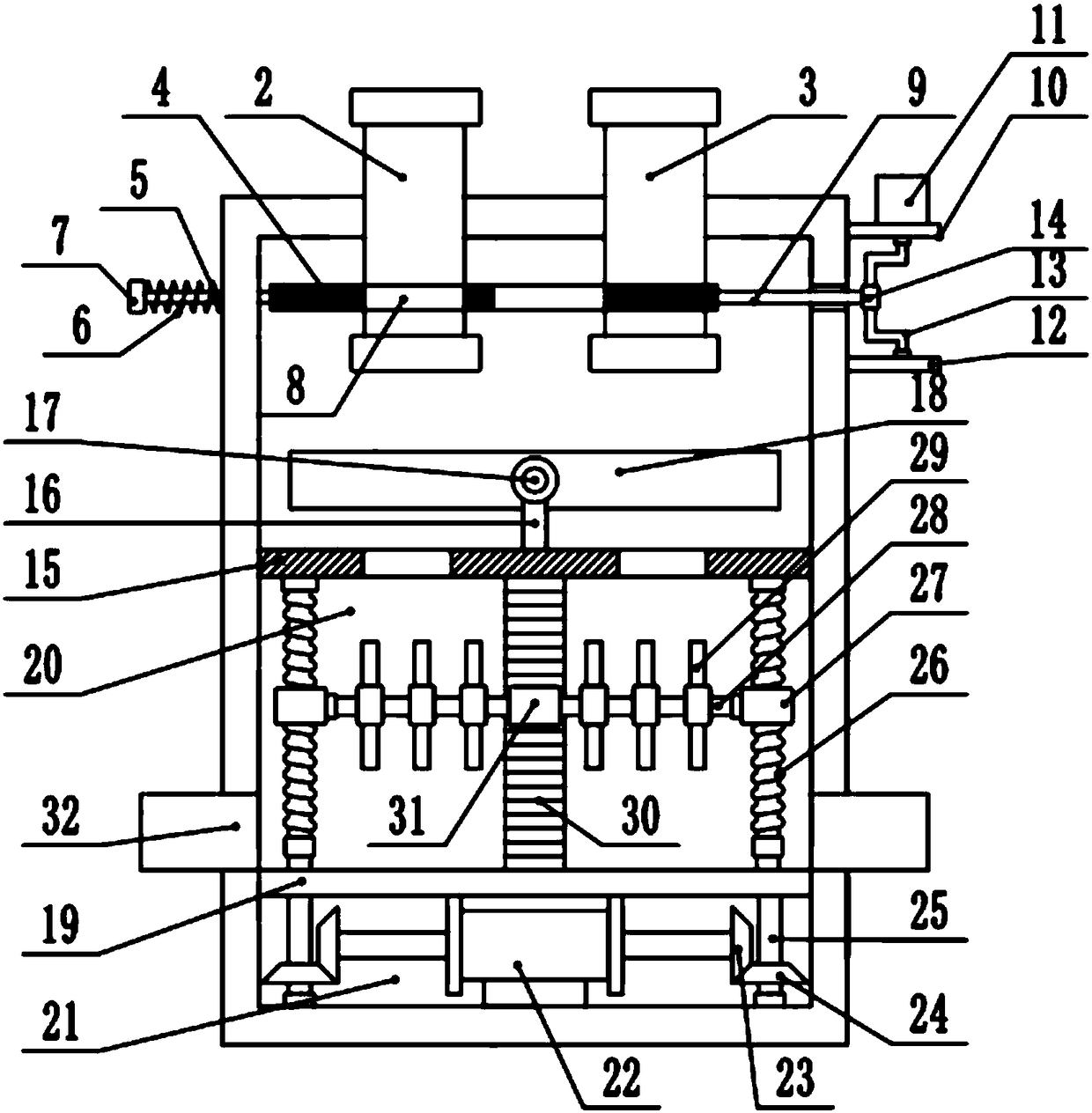

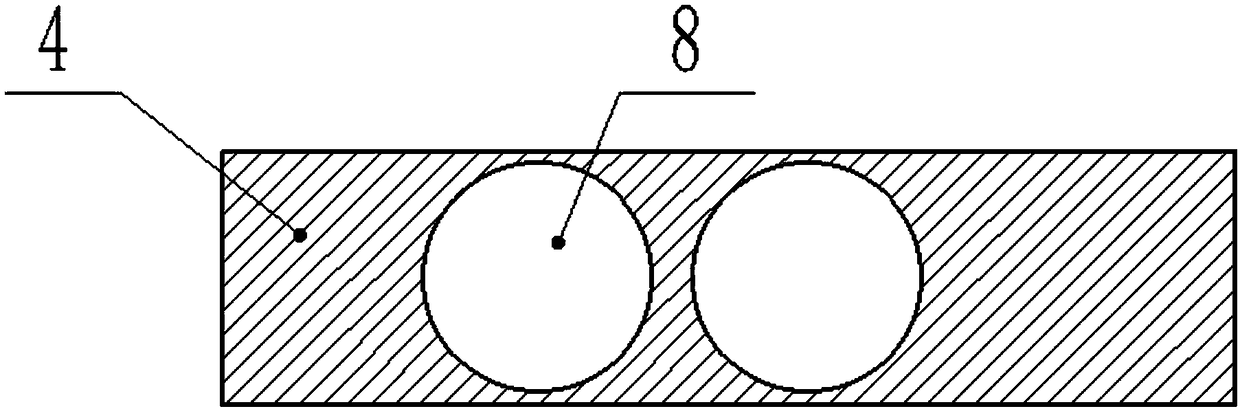

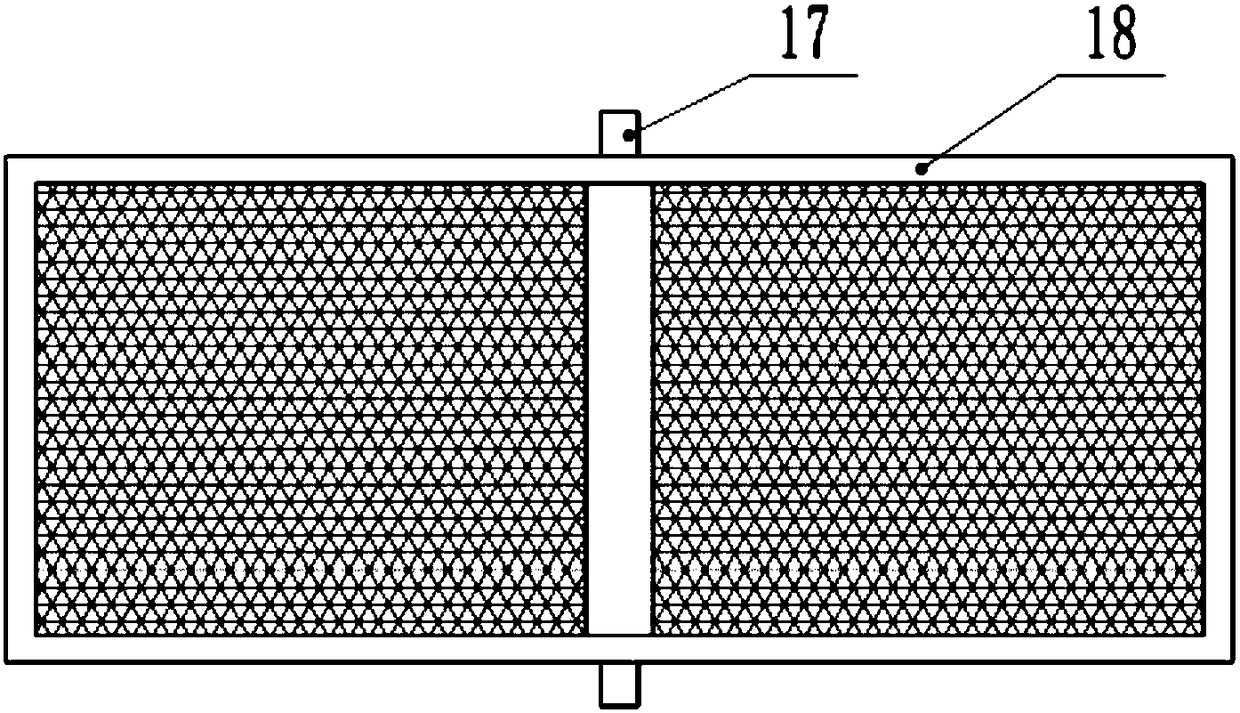

[0031] see Figure 1-3 , a kind of crankshaft-driven interval feeding type resin paint blending device, comprising a blending box 1, a material partition plate 4, a first drive motor 11, a second material blocking plate 13 and a filter tank 18, and the upper side of the blending box 1 is respectively provided with The first feed port 2 and the second feed port 3, the first feed port 2 and the second feed port 3 are circular through holes and the first feed port 2 and the second feed port 3 are inlaid with feed pipes, One end of the feeding pipe is connected with the external liquid feeding device, and the material separating plate 4 is slidably installed on the feeding pipe, and the material separating plate 4 is opened with a material leakage hole 8, and the material leakage hole 8 is a circular through hole, and the circular through hole The dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com