Device for preparing flocculant

A preparation device and flocculant technology, which is applied in the direction of flocculation/sedimentation water/sewage treatment, transportation and packaging, mixers, etc., can solve the problems of resource waste, flocculant powder agglomeration at adding speed, pipeline blockage, etc., and reduce fine Particles, increase the collision frequency, good stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

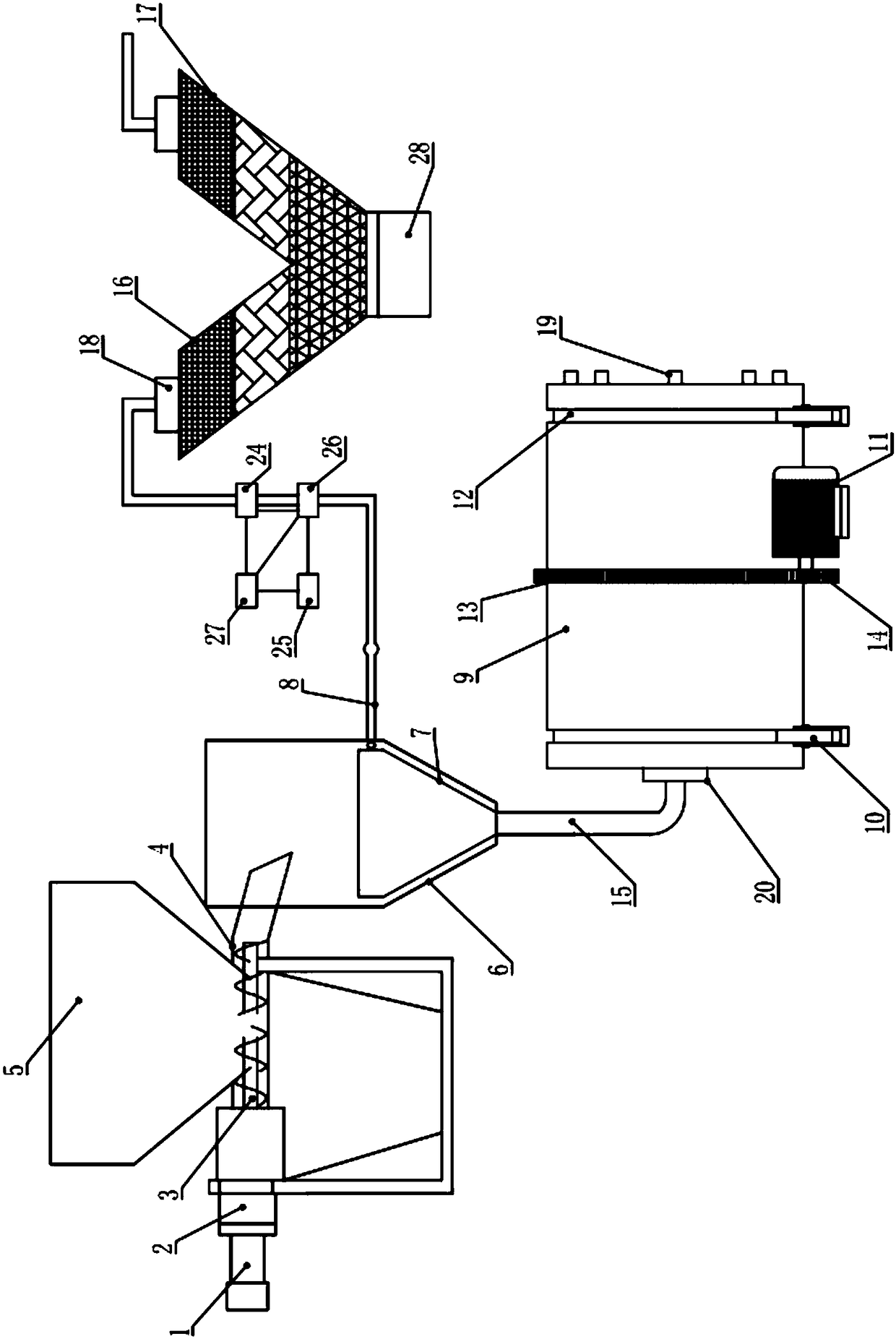

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] like Figure 1 to Figure 7 As shown, the flocculant preparation device includes a screw transport device, a cyclone, a stirring device, and a water purification device;

[0030] The screw conveying device includes motor A1, reducer 2, rotating shaft 3, feeding cylinder 4, and hopper 5. Motor A1, reducer 2, and rotating shaft 3 are connected in sequence. 4, the hopper 5 is fixedly connected with the feeding barrel 4 and the lower end of the hopper 5 extends into the feeding barrel 4;

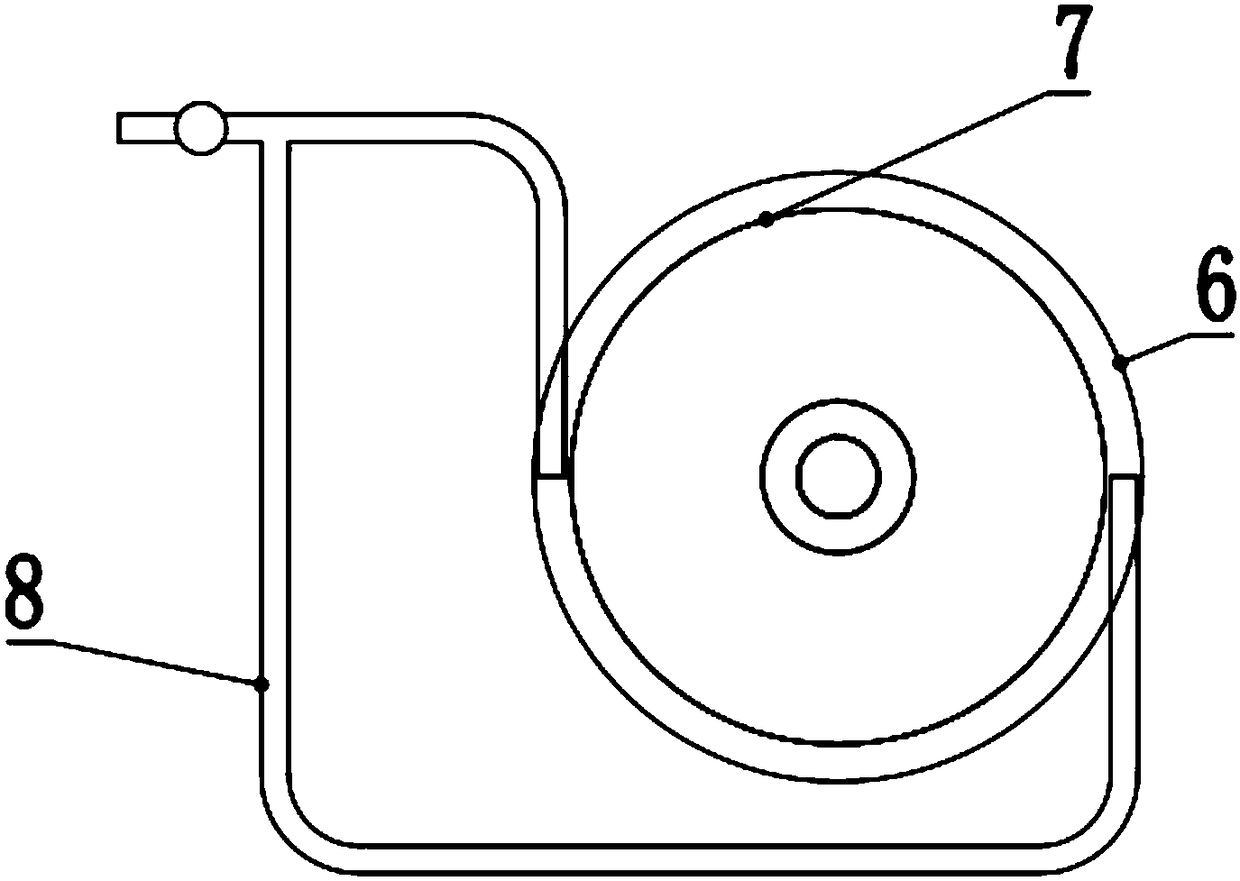

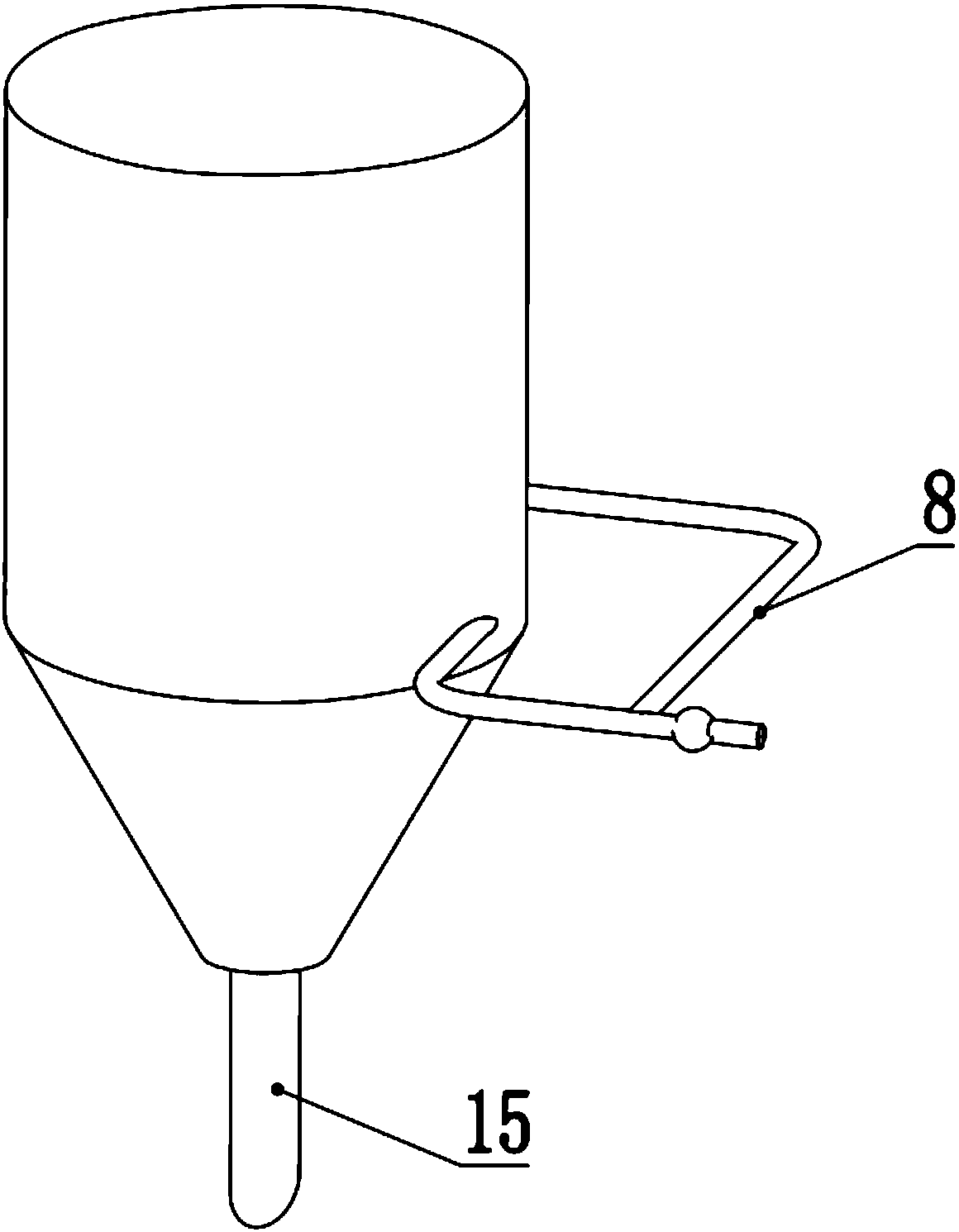

[0031] The cyclone includes an outer funnel 6, an inner funnel 7, and a water inlet pipe 8. The upper and lower ends of the outer funnel 6 are closed, the upper end of the inner funnel 7 is open, and the lower end is fixedly connected with the outer funnel 6. The inner funnel 7 and the outer funnel 6 are arranged coaxially. , the center of the bottom end of the outer funnel 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com