Full-automatic feeding and discharging intelligent manipulator for paper model

An intelligent manipulator, fully automatic technology, applied in manipulators, program-controlled manipulators, conveyors, etc., can solve the problems of poor overall structural stability, long cantilever pulling and pulling, etc., to reduce load bearing, enhance structural stability, and achieve high transmission accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present application will be further described below in conjunction with the accompanying drawings and specific embodiments.

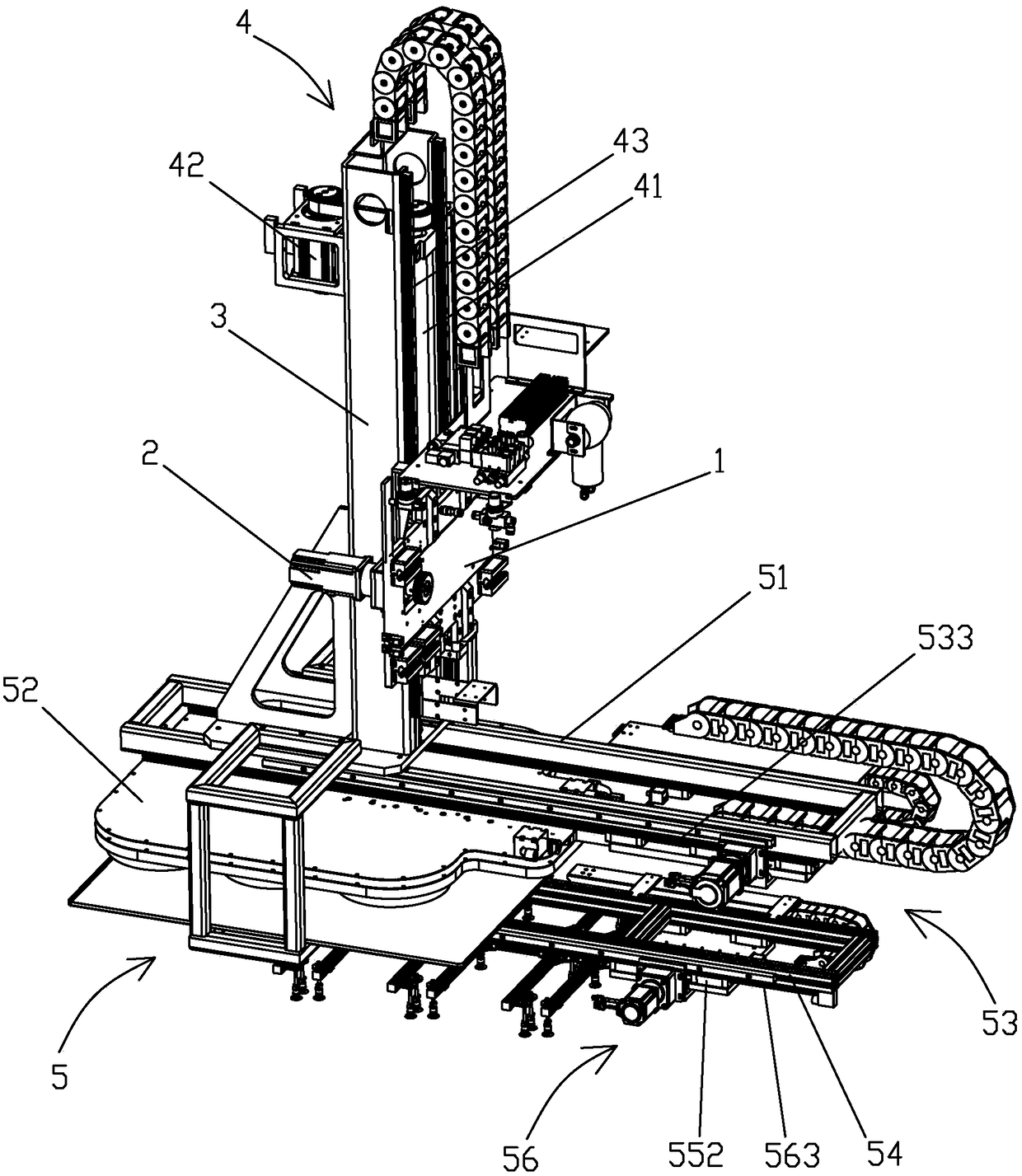

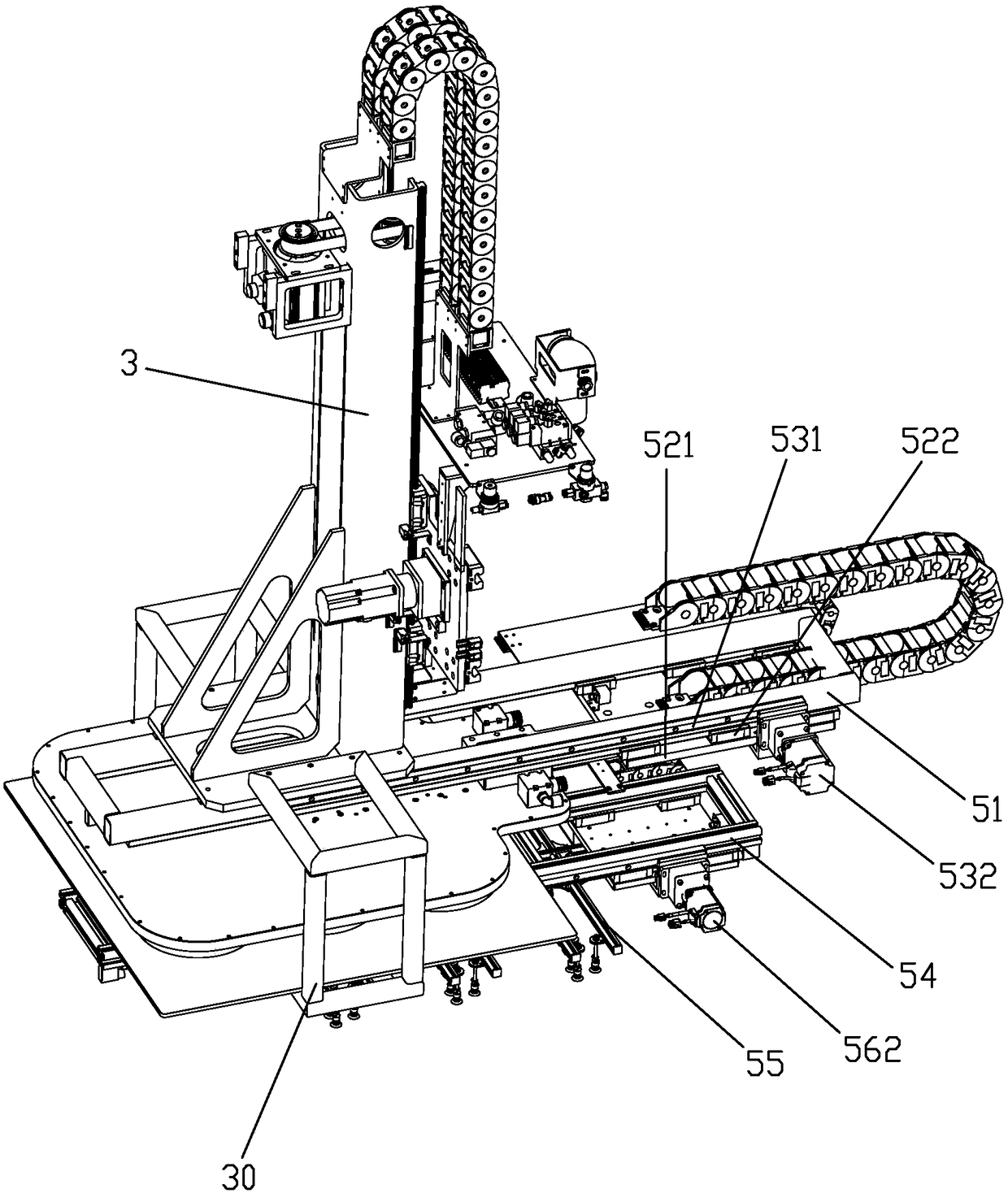

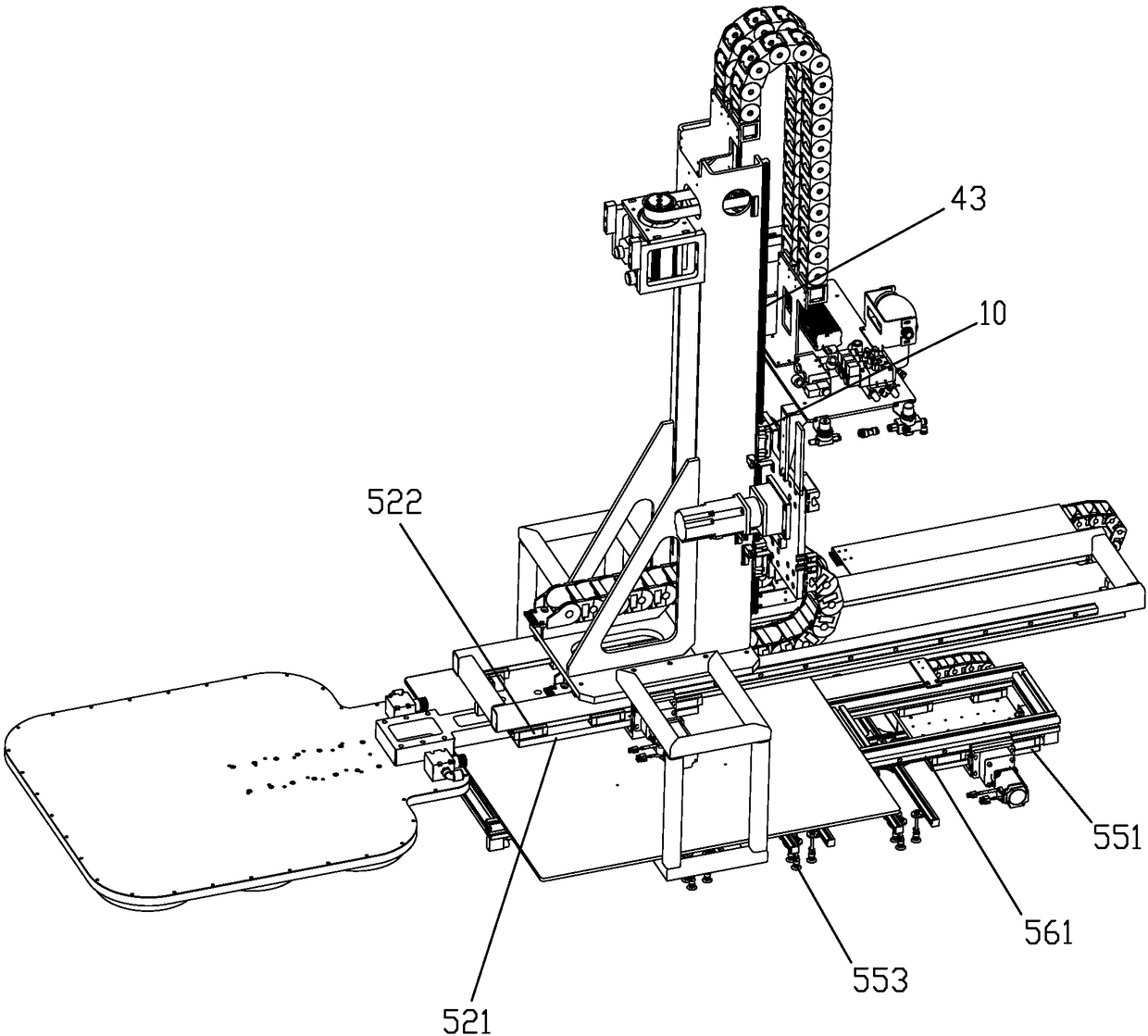

[0041] Please see attached figure 1 To attach Figure 5 , an intelligent manipulator for fully automatic loading and unloading of paper molds, including a horizontal sliding support 1, a horizontal driving structure 2, a lifting bracket 3, a vertical driving mechanism 4 and a paper mold adsorption assembly 5. in:

[0042] The transverse sliding support 1 is slidably connected to the support frame of the paper mold forming equipment, and the transverse driving mechanism 2 is arranged on the transverse sliding support 1 for driving the transverse sliding support 1 to reciprocate and slide laterally along the support frame. Specifically, the lateral drive mechanism 2 includes a lateral drive motor 21 arranged on the lateral sliding support 1, and the output shaft of the lateral drive motor 21 is provided with a lateral gear meshed with a later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com