Kiwi wine processing device

A processing device and kiwifruit technology, applied in the field of fruit processing, can solve the problems of increased air pressure, increased enterprise cost, carbon dioxide gas explosion, etc., and achieve the effects of expanding the stirring range, reducing time costs, and fast crushing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail through specific implementation methods:

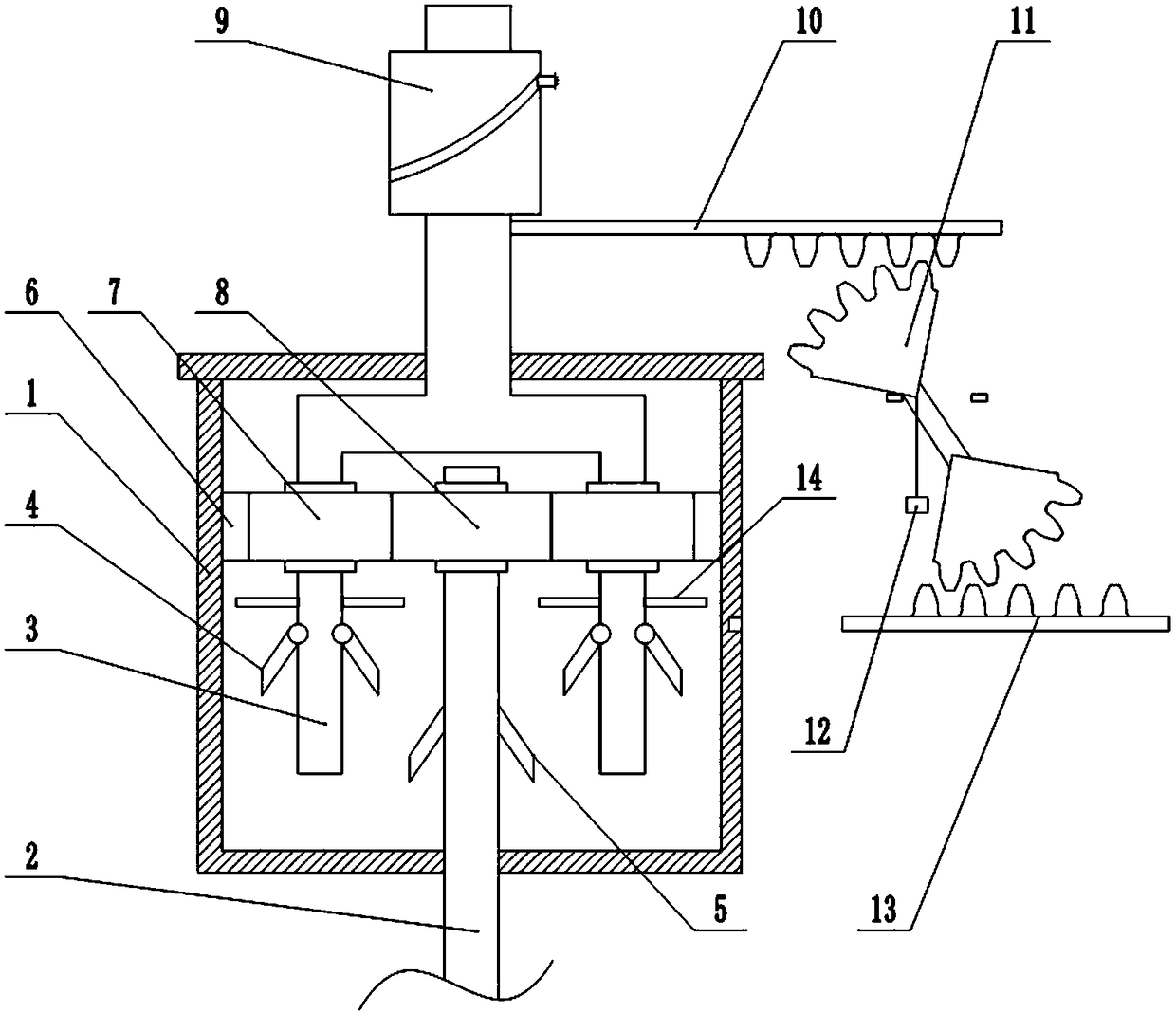

[0022] The reference signs in the drawings of the description include: stirring tank 1, stirring shaft 2, planet carrier 3, second stirring blade 4, first stirring blade 5, inner ring gear 6, planetary gear 7, sun gear 8, cylindrical cam 9 , The second rack 10, the sector gear 11, the counterweight 12, the first rack 13, the pressing plate 14.

[0023] like figure 1 As shown, the kiwi fruit wine processing device includes a frame, a stirring tank 1 is rotatably connected to the frame, and a stirring shaft 2 is rotatably connected in the stirring tank 1, and the lower end of the stirring shaft 2 extends through the bottom of the stirring tank 1, and the frame is also provided with There is a motor, and the output shaft of the motor is fixedly connected with the lower end of the stirring shaft 2. The portion of the stirring shaft 2 inside the stirring tank 1 is evenly distributed wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com