A high-efficiency high-temperature solidification process for silicon carbide seed crystals

A high-temperature solidification and silicon carbide technology, which is applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of ordinary fixing effect and affecting the quality of crystal growth, etc., and achieve good effect, full and efficient use, and good high temperature resistance effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

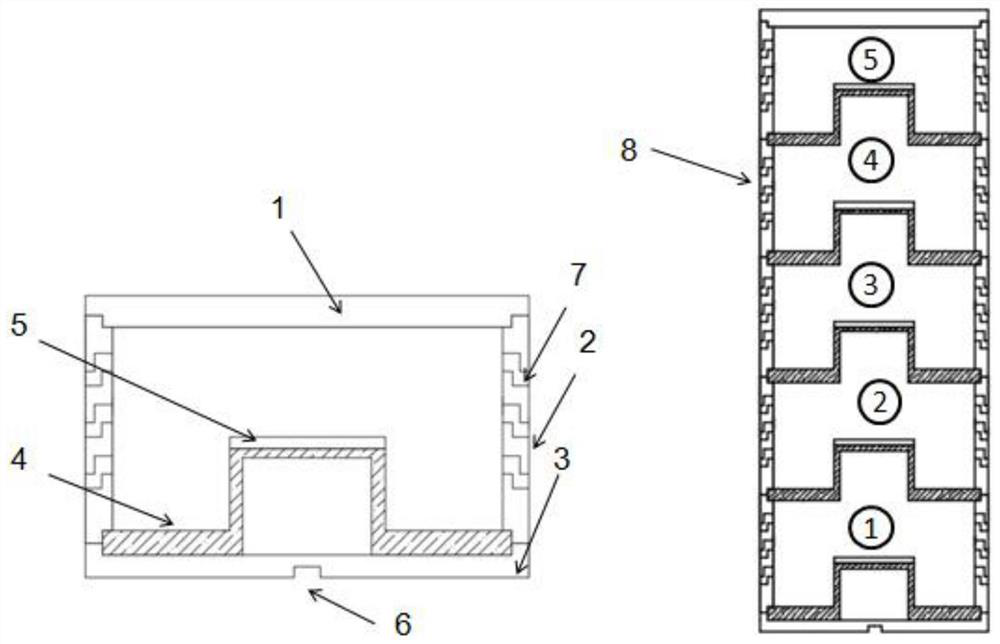

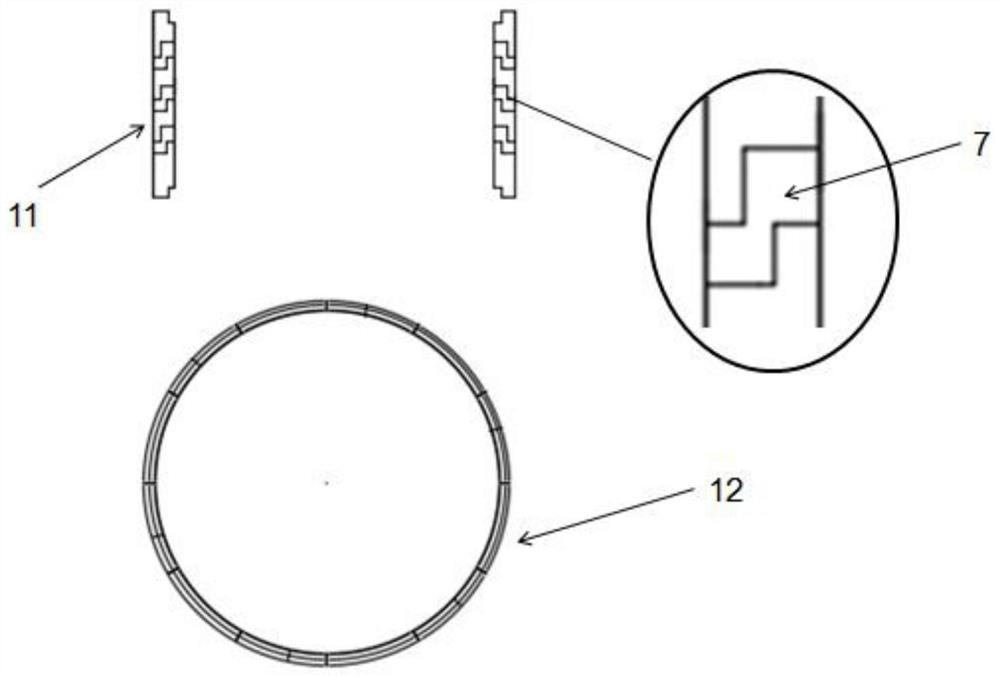

[0042] A high-efficiency high-temperature solidification process for silicon carbide seed crystals, using a crucible fixture having a lid, a crucible cover, a crucible with a thickness of 10 mm, a chassis, a chassis temperature measuring hole with a diameter of 5 mm, and a vent hole for high-temperature solidification of silicon carbide seed crystals ;Each two adjacent air holes with a diameter of 10mm form an inverted zigzag shape, the central axes of the two holes are respectively inclined at 5° to the horizontal line, and the central axes of the inner and outer holes are separated by 1 / 4 of the diameter of the air holes, and they overlap in the center of the crucible wall. The inner hole is at a high position; the crucible fixture is made of graphite material; the temperature measurement hole of the chassis adopts an infrared high temperature thermometer to measure and control temperature; including the following steps:

[0043] Step S1, use carbon glue to stick the silicon ...

Embodiment 2

[0052] A process for high-efficiency high-temperature solidification of silicon carbide seed crystals, using a crucible fixture with a lid, a crucible cover, a crucible with a thickness of 30mm, a chassis, a temperature measuring hole with a diameter of 20mm, and a vent hole for high-temperature solidification of silicon carbide seed crystals ;Each two adjacent air holes with a diameter of 30mm form an inverted zigzag shape, the central axes of the two holes are respectively inclined at 15° to the horizontal line, and the central axes of the inner and outer holes are separated by 1 / 4 of the diameter of the air holes, which overlap in the center of the crucible wall. The inner hole is at a high position; the crucible fixture is made of graphite material; the temperature measurement hole of the chassis adopts an infrared high temperature thermometer to measure and control temperature; including the following steps:

[0053] Step S1, use carbon glue to stick the silicon carbide se...

Embodiment 3

[0062] A process for high-efficiency high-temperature solidification of silicon carbide seed crystals, using a crucible fixture with a lid, a crucible cover, a crucible with a thickness of 20mm, a chassis, a chassis temperature measuring hole with a diameter of 12.5mm, and a vent hole for high temperature of the silicon carbide seed crystal. Solidification; every two adjacent air holes with a diameter of 20mm in the ventilation holes form an inverted Z shape, the central axes of the two holes are respectively inclined at 10° to the horizontal line, and the central axes of the inner and outer holes are separated by 1 / 4 of the diameter of the air holes, which meet at the center of the crucible wall. The overlap is connected and the inner hole is at a high position; the crucible fixture is made of graphite material; the temperature measuring hole of the chassis adopts an infrared high temperature thermometer to measure and control temperature; including the following steps:

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com