Rotating power output built-in hydraulic rock drilling machine

A hydraulic rock drill and rotary power technology, which is applied in the field of hydraulic rock drills, can solve problems such as unfavorable on-site installation and maintenance, damage to the output shaft of the cantilever, and many falling rocks, so as to facilitate the installation and maintenance of the rock drill, slow down the axial movement force, and save space volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

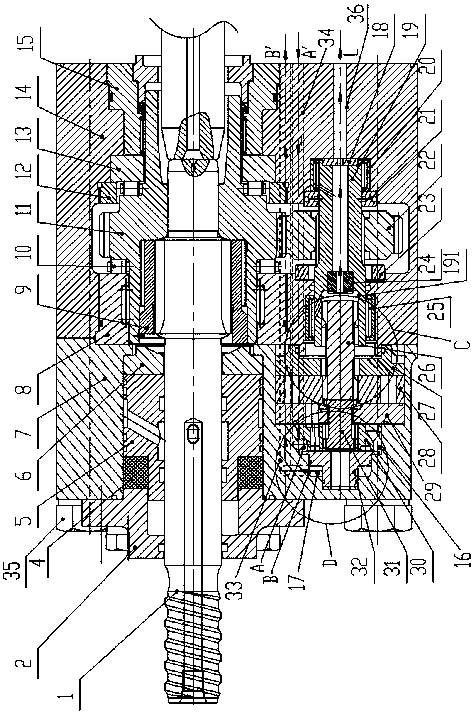

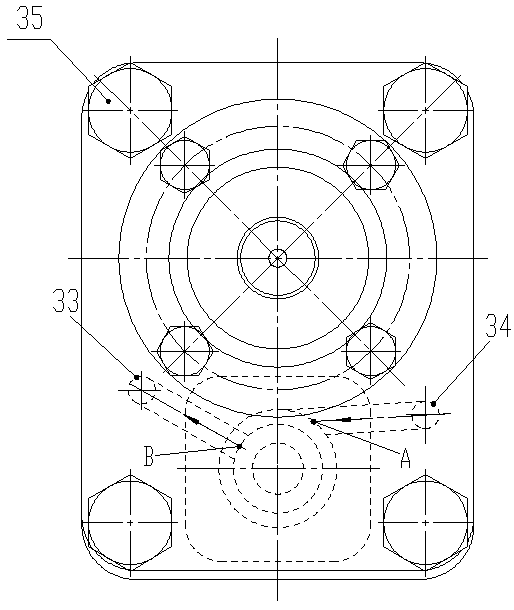

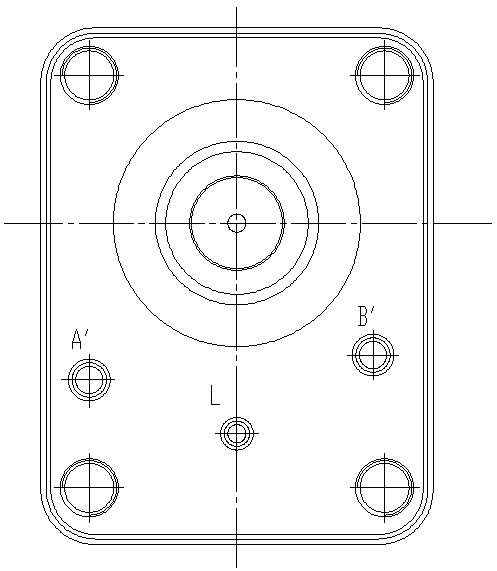

[0045] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0046] Such as Figure 1-7 As shown, a hydraulic rock drill with a built-in rotary power output of the present invention includes a box cover 7, a box body 14 connected to the box cover 7, a transmission part, and a power output part;

[0047] The transmission part includes the shank 1 passing through the box body 14 and the box cover 7, the gland 2 fixed on the left end surface of the box cover 7, the water jacket 5 installed in the box cover 7, the guide sleeve 9, and the A hollow gear shaft 11, the gear shaft 11 is coaxially arranged on the peripheral surface of the shank 1;

[0048] The right side of the gear shaft 11 is provided with a rear bearing 15 and a friction plate 13 installed in the box body 14 from right to left and supported on the circumferential surface of the right side of the gear shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com