Hydrogen liquefaction device

A liquefaction device and hydrogen technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of low liquefaction efficiency and large investment, achieve the effects of small evaporation loss, reduce safety hazards, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

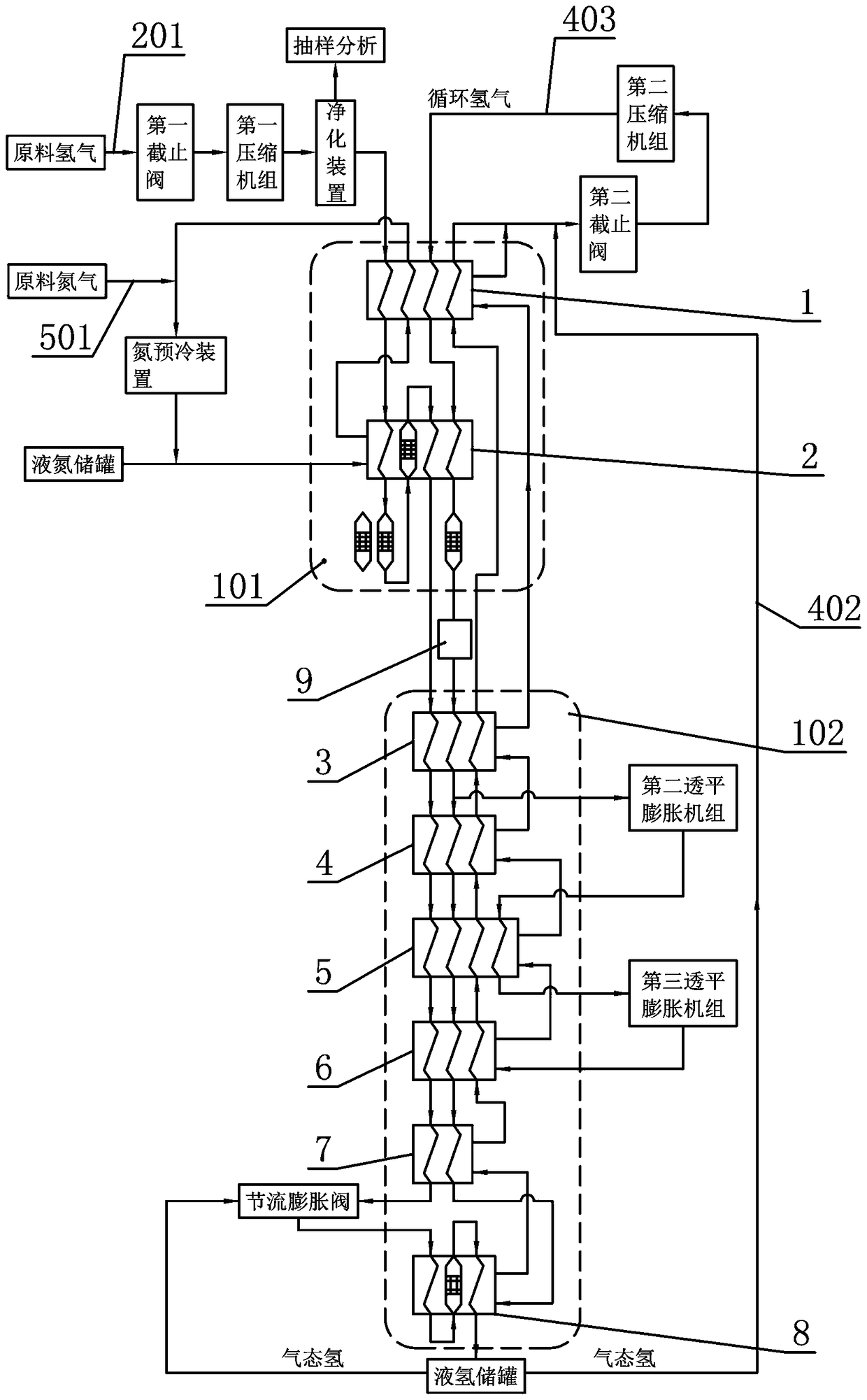

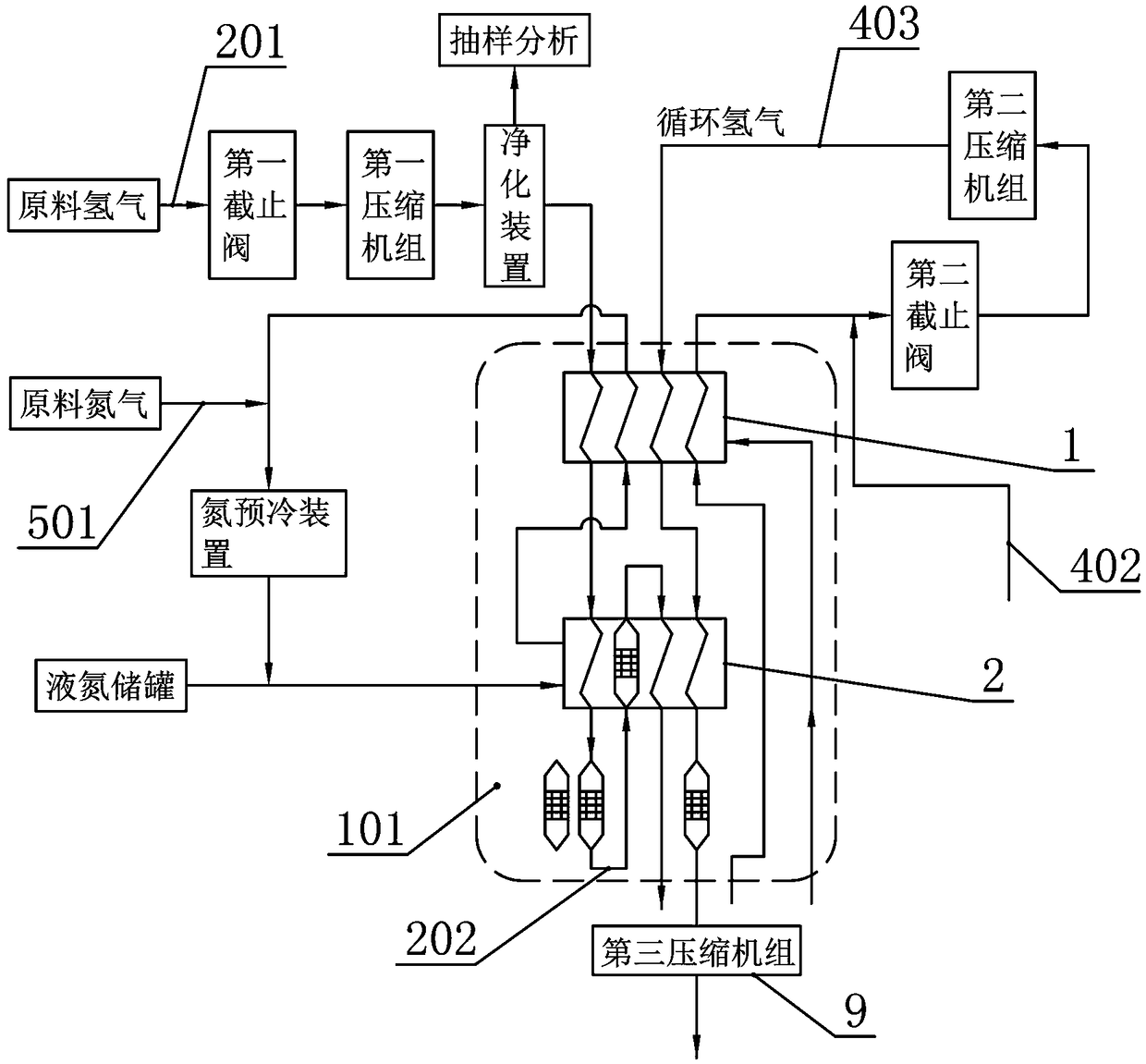

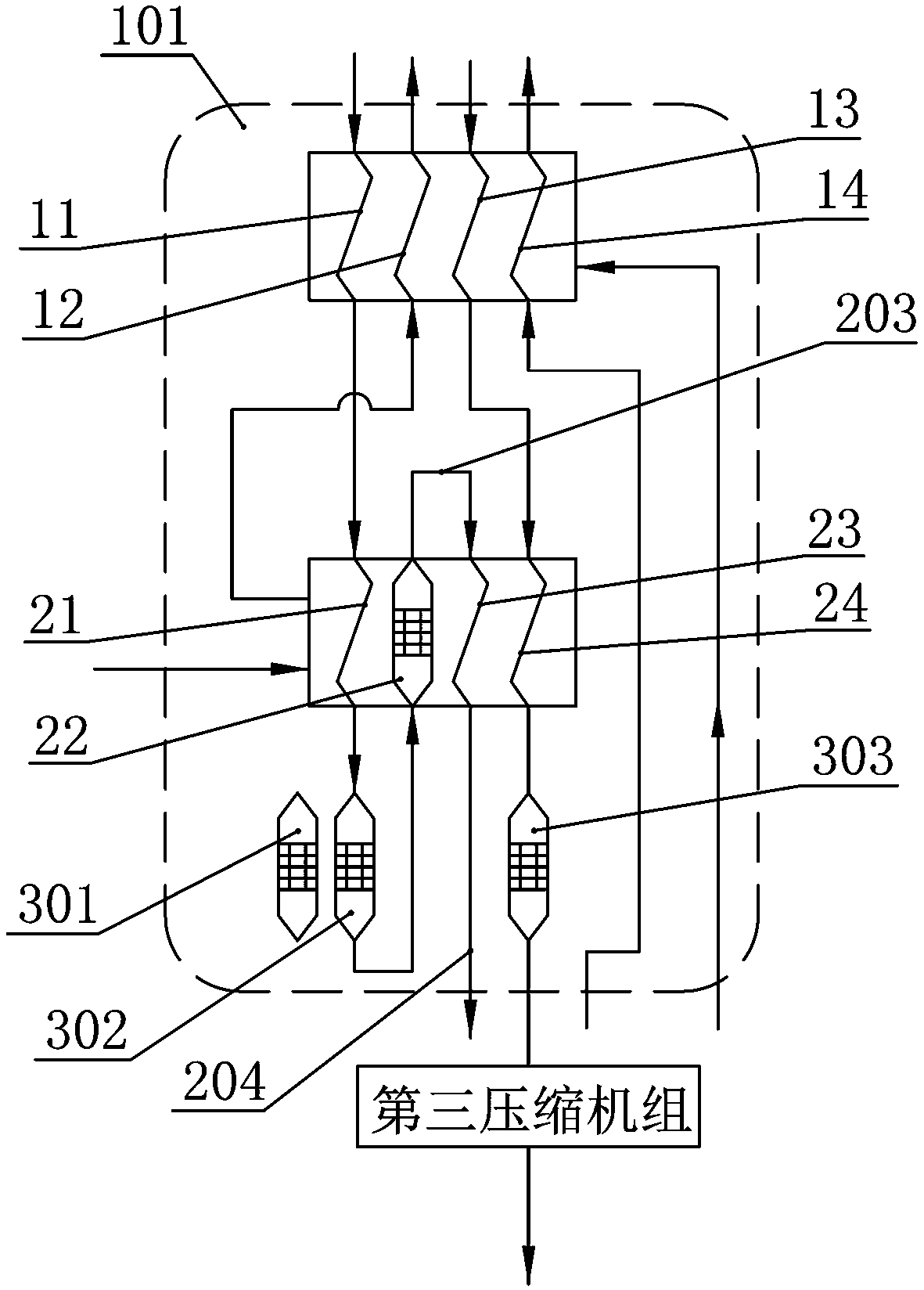

[0032] The technical scheme of the present invention will be further described in detail below in conjunction with the drawings and preferred embodiments.

[0033] Such as figure 1 As shown, the structure of the hydrogen liquefaction device is: including a first compressor unit, a purification device, a first cold box 101, a second cold box 102, a throttle expansion valve, a liquid hydrogen storage tank, a liquid nitrogen pre-cooling device, The second compressor group and the third compressor group 9.

[0034] The first compressor unit includes: a first low-pressure compressor and a first high-pressure compressor. The first low-pressure compressor can be a low-pressure unit-screw-filled compressor or a low-pressure dry piston multi-stage compressor. The machine can adopt a high-pressure unit-dry piston multi-stage compressor.

[0035] The purification device includes: a clean oil adsorber, a catalytic refining device, a drying device and an adsorber capable of removing impurities w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com