A small wheel tooth surface design method and processing method for meshing performance pre-control

A design method and processing method technology, applied in the field of gear transmission, can solve the problems of reducing transmission strength, tooth surface deviation, and low processing efficiency, and achieve high flexibility and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

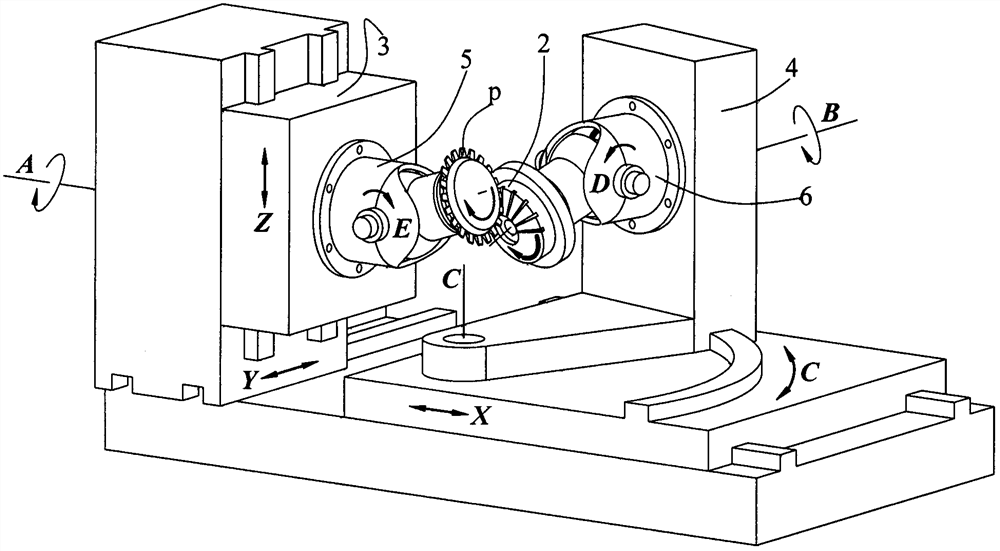

[0062] Embodiment: Design method and processing method of small wheel tooth surface in oblique offset helical tooth surface gear transmission.

[0063] The design method of the pinion tooth surface includes the following steps: preset of geometric transmission error, reverse calculation of pinion tooth surface, reconstruction of pinion tooth surface, (1) preset of geometric transmission error, as shown in steps S101-S104 :

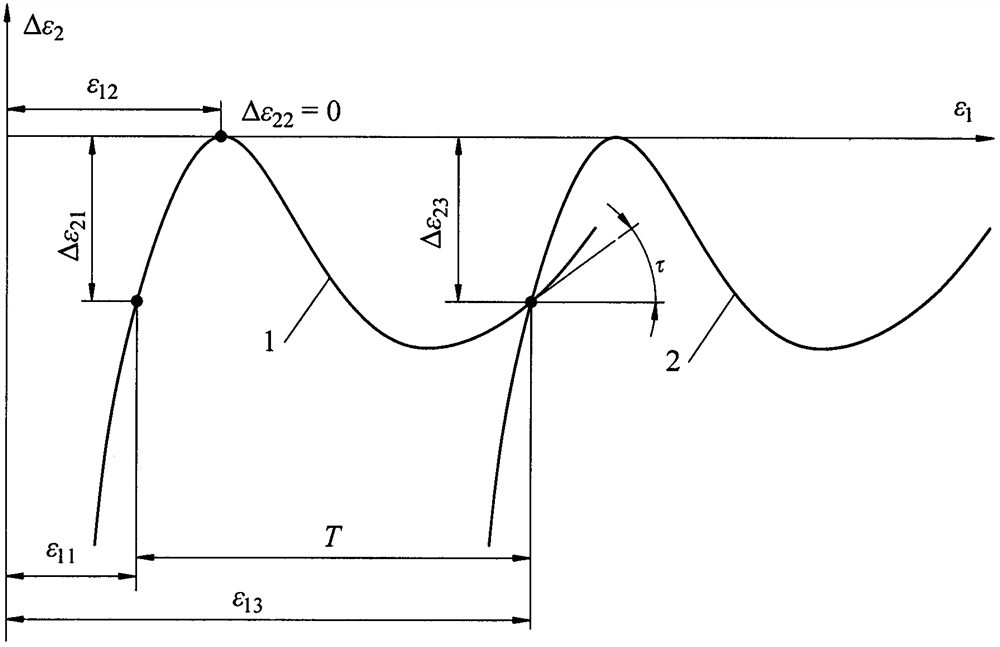

[0064] S101 Construct geometric transmission error polynomial the c 0 , c 1 , c 2 ,...,c σ is the undetermined coefficient, σ is the order of geometric transmission error polynomial, which is a positive integer between 2 and 8, ε 1 is the wheel turning angle;

[0065] S102 Determine the shape of the geometric transmission error curve according to the magnitude of the expected geometric transmission error in the meshing period and the slope at the intersection of adjacent geometric transmission errors, image 3 It is a 4th-order transmission error c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com