Ship model and manufacturing method of ship model

A manufacturing method and ship model technology, which is applied in the field of ship models, can solve the problems of large ship model errors, etc., and achieve the effects of reducing part errors, improving utilization, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

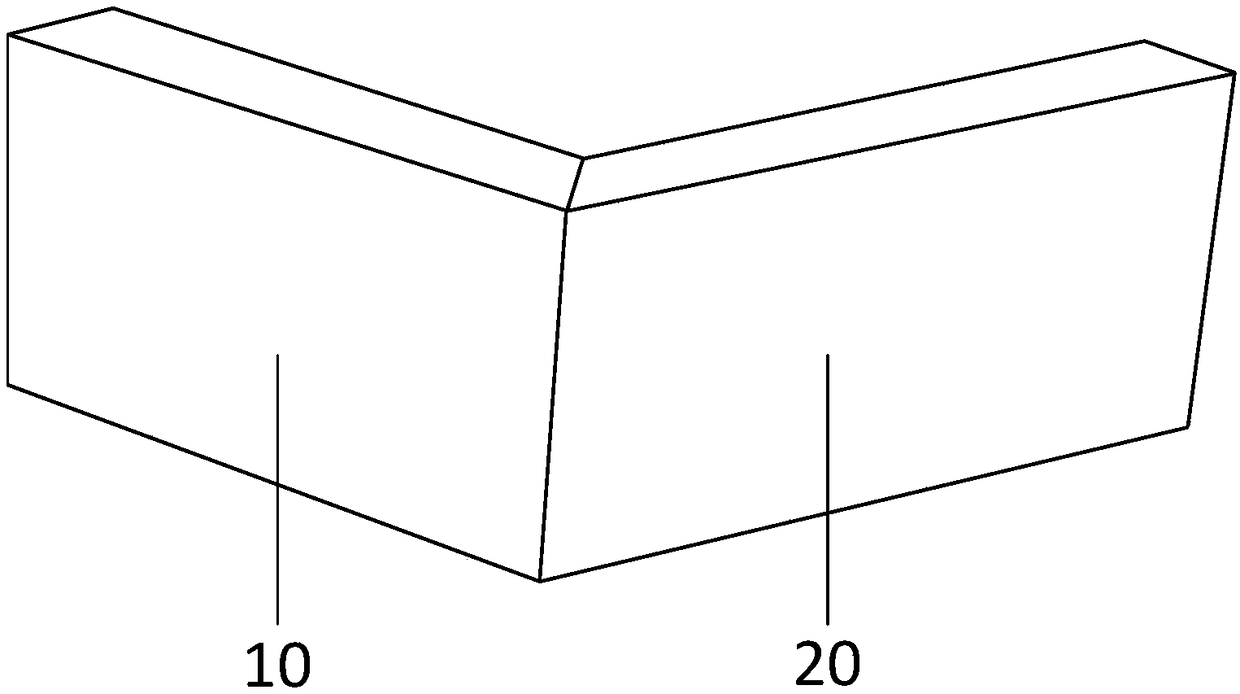

[0040] An embodiment of the present invention provides a ship model, including several interconnected ship model parts, wherein, such as Figure 4b As shown, the joints of the ship model parts are chamfered joints. The chamfering has a first chamfering distance d1 and a second chamfering distance d2, and the ratio of the first chamfering distance d1 to the second chamfering distance d2 is 1:1 to 1:3.

[0041] The size of the ship model can be better controlled by setting the joints between the parts of the ship model as chamfered joints, and the error of parts can be reduced.

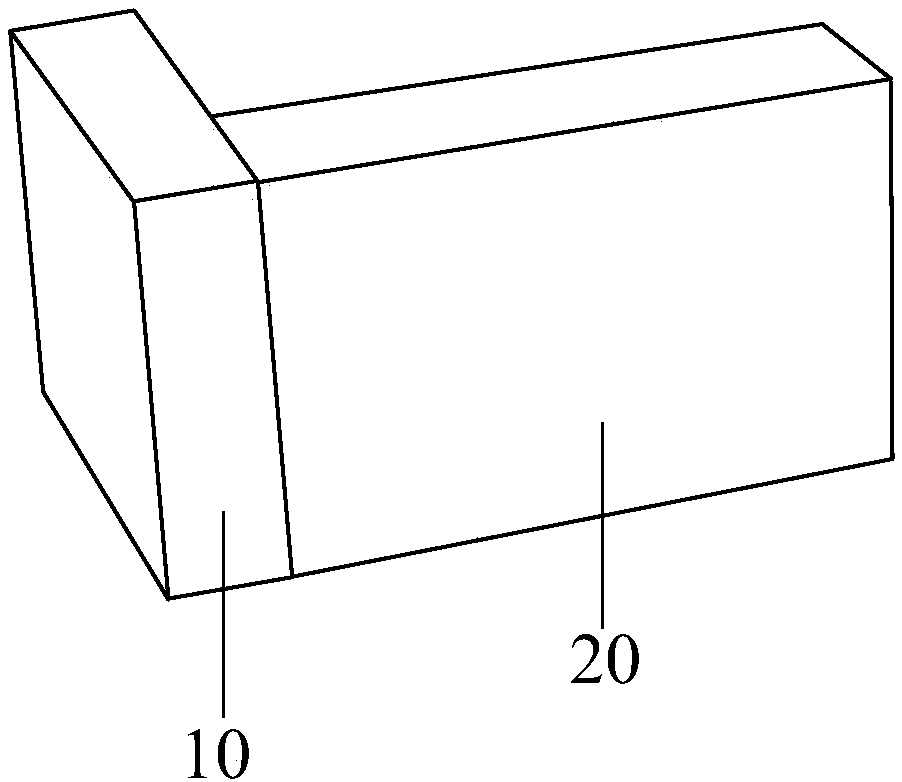

[0042] Such as figure 2 As shown, the joint of the first ship model part 10 and the second ship model part 20 in the ship model is chamfered joint. Among them, the first chamfering distance d1 and the length, minimum thickness and shear strength of each ship model component meet the preset conditions. Specifically, the first chamfering distance can be calculated using the following formula:

[0043]...

Embodiment 2

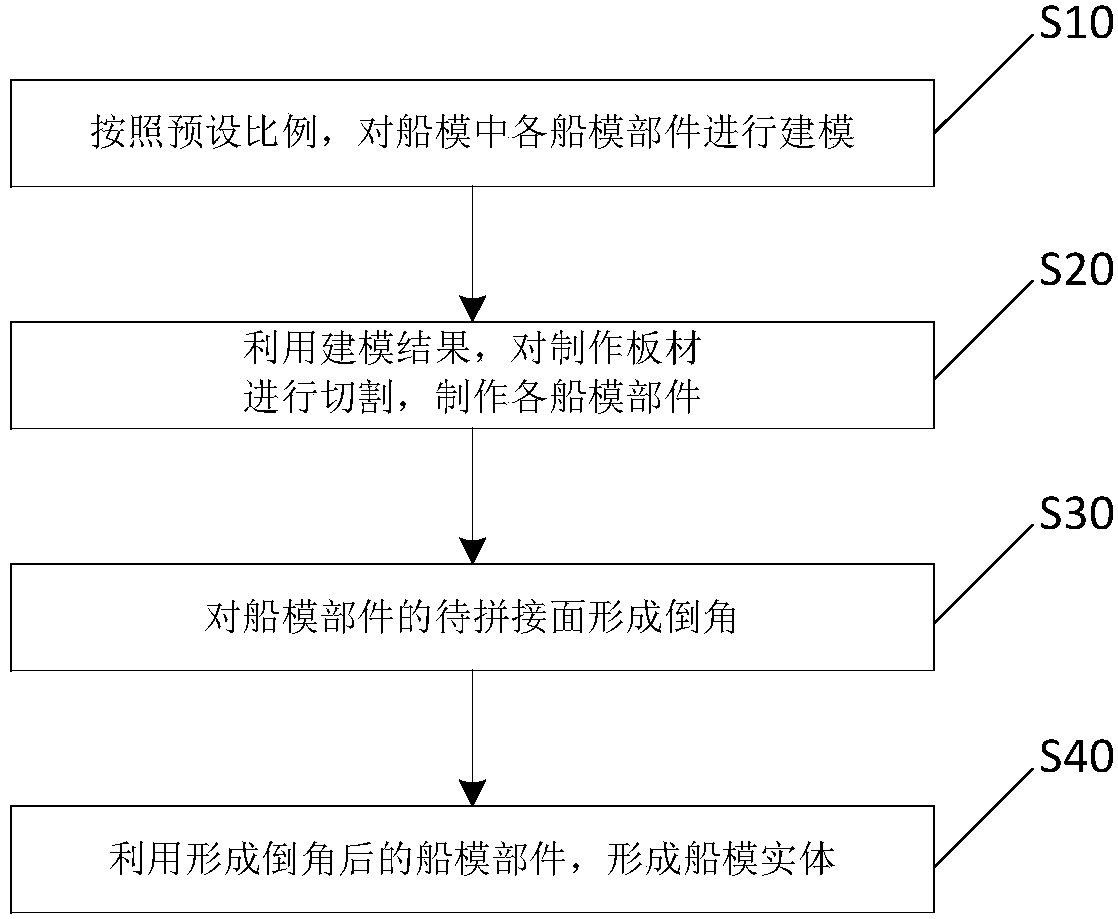

[0050] The embodiment of the present invention provides a kind of manufacturing method of ship model, such as image 3 shown, including the following steps:

[0051] Step S10, modeling each ship model component in the ship model according to a preset ratio, wherein the preset ratio is the ratio between the ship model and the real ship.

[0052] The ship model components that form the ship model are modeled by using the proportional relationship between the set ship model and the actual ship. Specifically, each ship model part is drawn according to a preset ratio, and each surface of each ship model part forming the ship model is drawn separately, so that it can be spliced into a complete ship model entity.

[0053] Optionally, the length of each surface of each ship model component can be calculated according to the thickness of the plate to reduce the error.

[0054] Step S20, using the modeling results to cut the production plate to produce various ship model components....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com