Continuous automatic production line used for processing stir-fried rice

An automatic production line and fried rice technology, which is applied in the field of food processing, can solve the problems of nutritional components and other problems, and achieve the effect of long shelf life, delicious color and taste, sweet and crisp taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

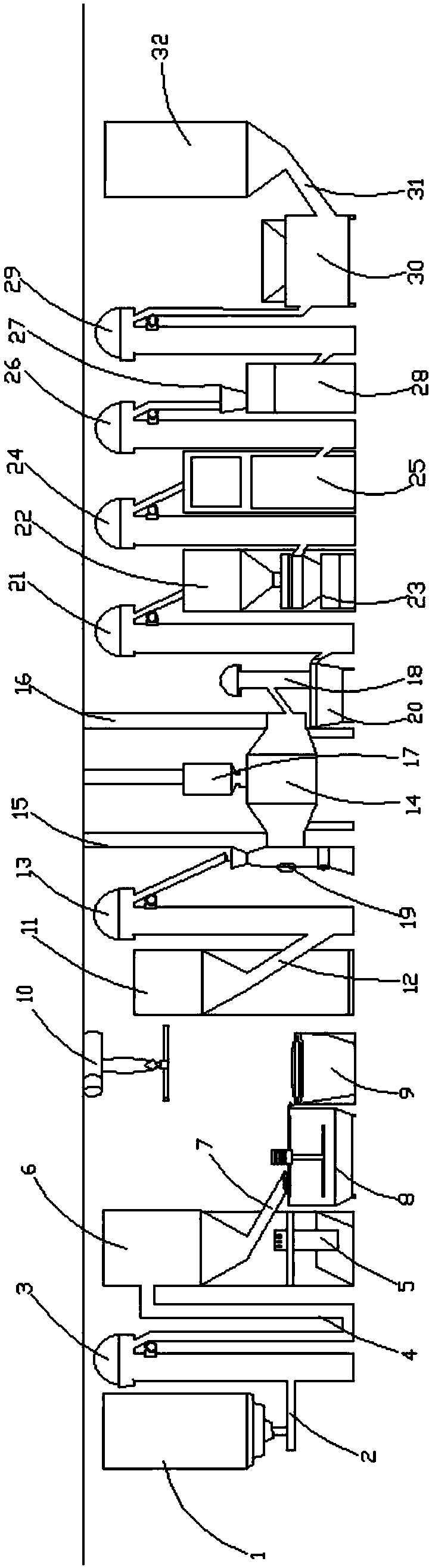

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Such as figure 1 As shown, the continuous automatic production line for processing fried rice includes a raw material bin 1, the lower end of the raw material bin 1 is connected to the primary screening device 2, and the primary screening device 2 is connected to the material conveying elevator I3 and connected to the automatic weighing device 5 through the material conveying pipeline I4 The material bin I6 is located above the automatic weighing device 5, and the outlet of the material bin I6 is connected to the top of the cooking pot 8 through the material conveying pipeline II7; An electric lifting device 10 is fixedly installed, which is used to lift the drain liner to facilitate draining; the upper material bin 11 is located at the upper end of the draining device 9, and the feeding port of the upper mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com