Building material pulverizer

A technology of building materials and pulverizers, applied in the field of building materials, can solve problems such as difficult separation of raw materials, and achieve the effect of convenient access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following is further described in detail through specific implementation methods:

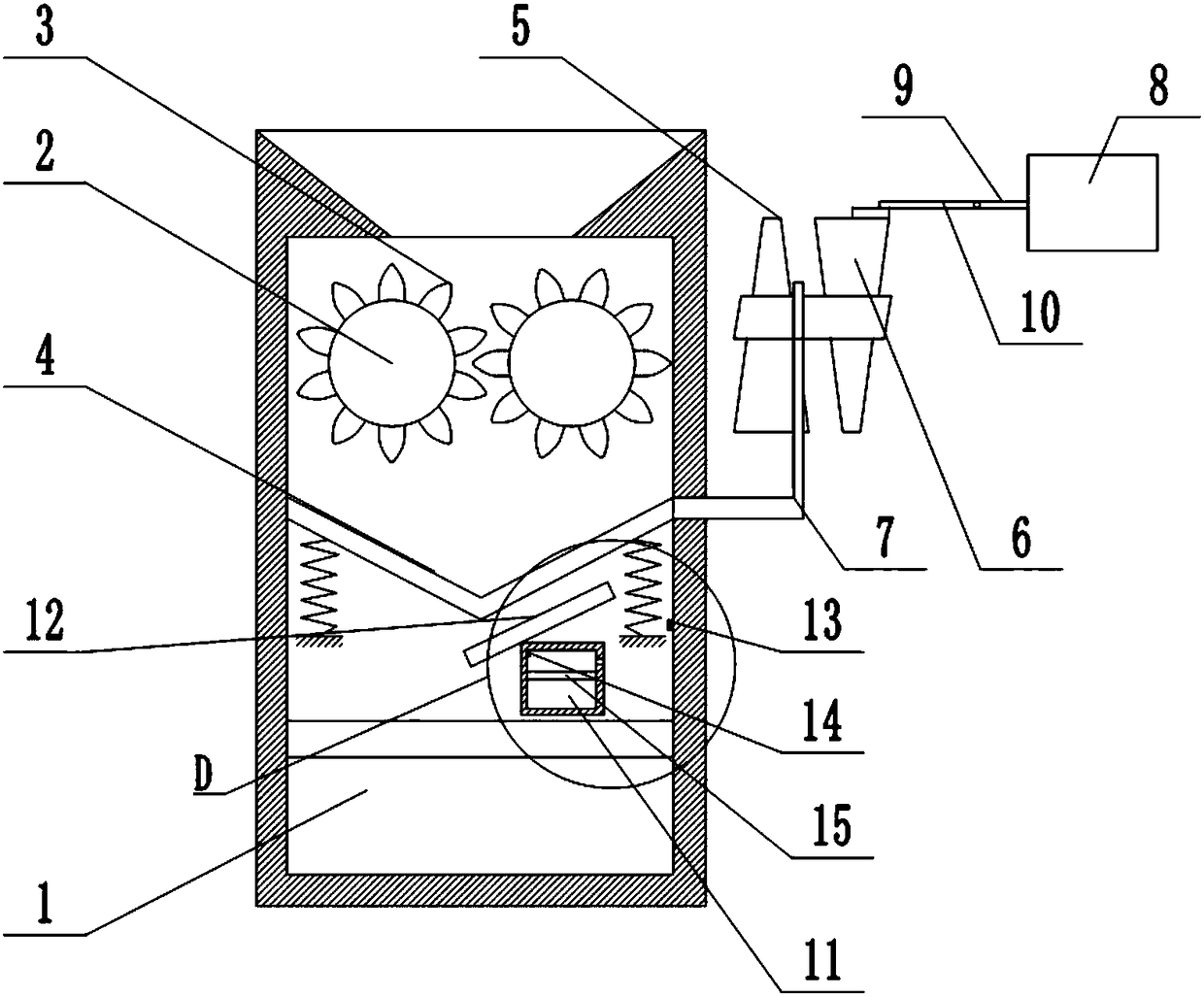

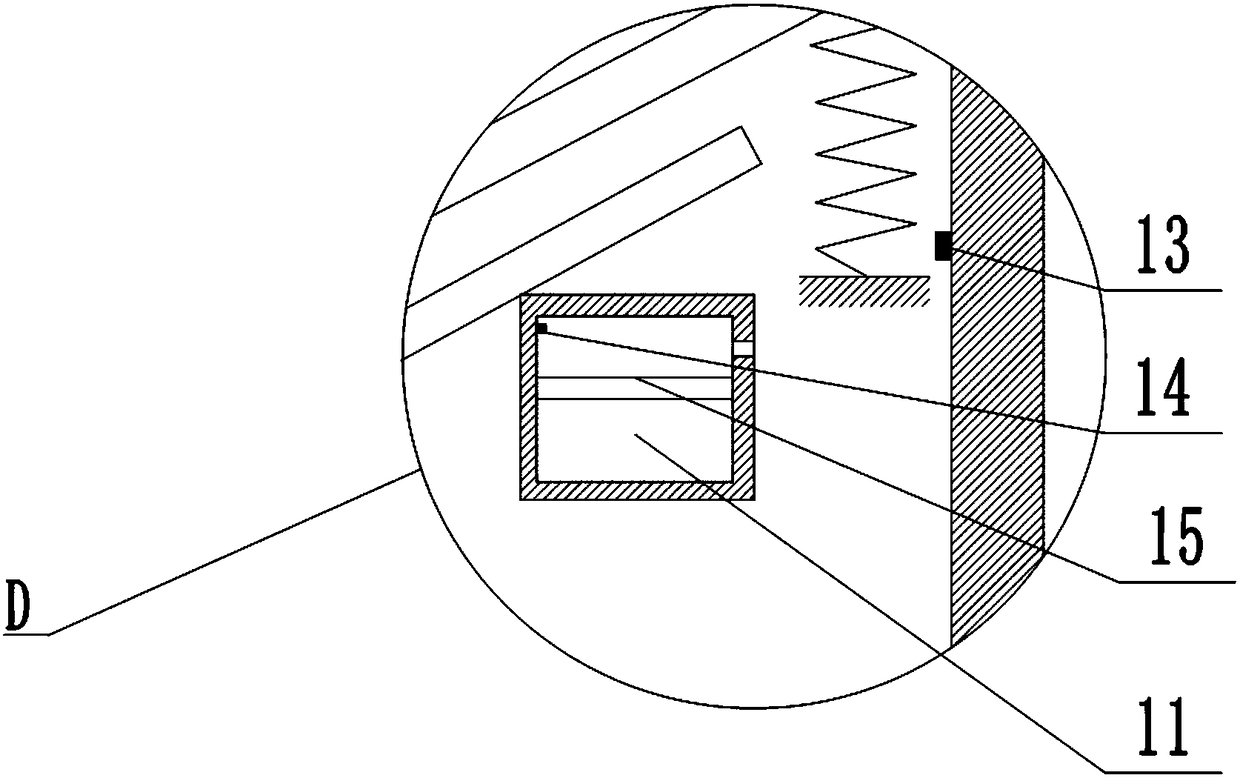

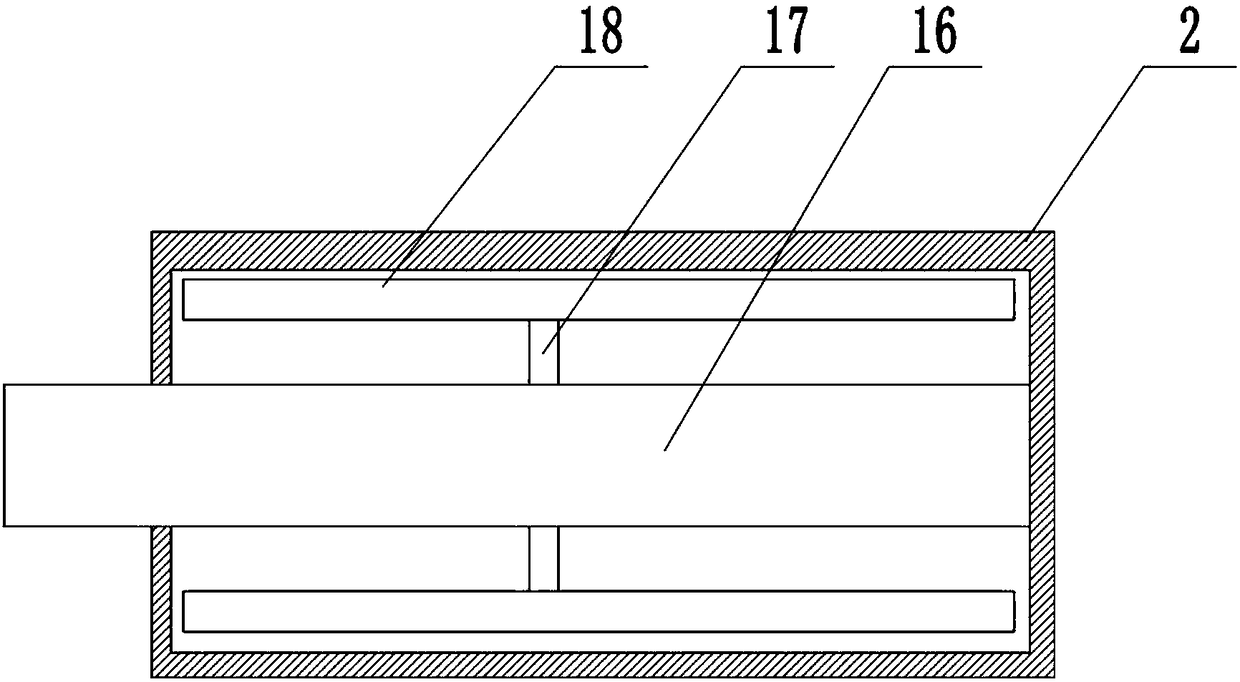

[0027] The reference signs in the accompanying drawings of the specification include: pulverizer body 1, airbag roller 2, protrusion 3, filter plate 4, drive shaft 5, driven shaft 6, shift fork 7, second piston barrel 8, first connecting rod 9. The second connecting rod 10, the first piston barrel 11, the guide plate 12, the second position switch 13, the first limit switch 14, the first piston 15, the mandrel 16, the elastic rod 17, and the magnetic plate 18.

[0028] Such as figure 1 As shown, the building material pulverizer includes a pulverizer body 1, and the pulverizer body 1 is sequentially provided with an inverted tapered feed inlet, an air bag roller 2, a filter plate 4, a first piston barrel 11, and a guide plate from top to bottom. 12 and the collection box, also including the drive unit.

[0029] The driving unit includes a driving shaft 5 and a driven shaft 6 located...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com