Finish machining method for blank part with basic hole

A technology of reference holes and parts, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of poor cost quality, long calibration time, and difficult control of processing dimensions, so as to reduce the calibration process and improve the processing quality. , the effect of reducing the processing risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

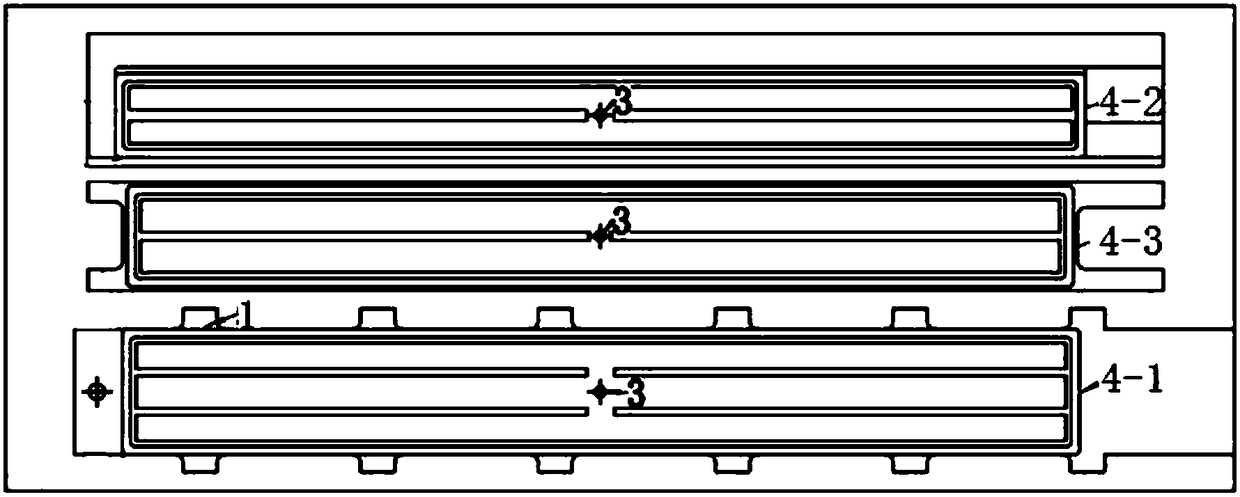

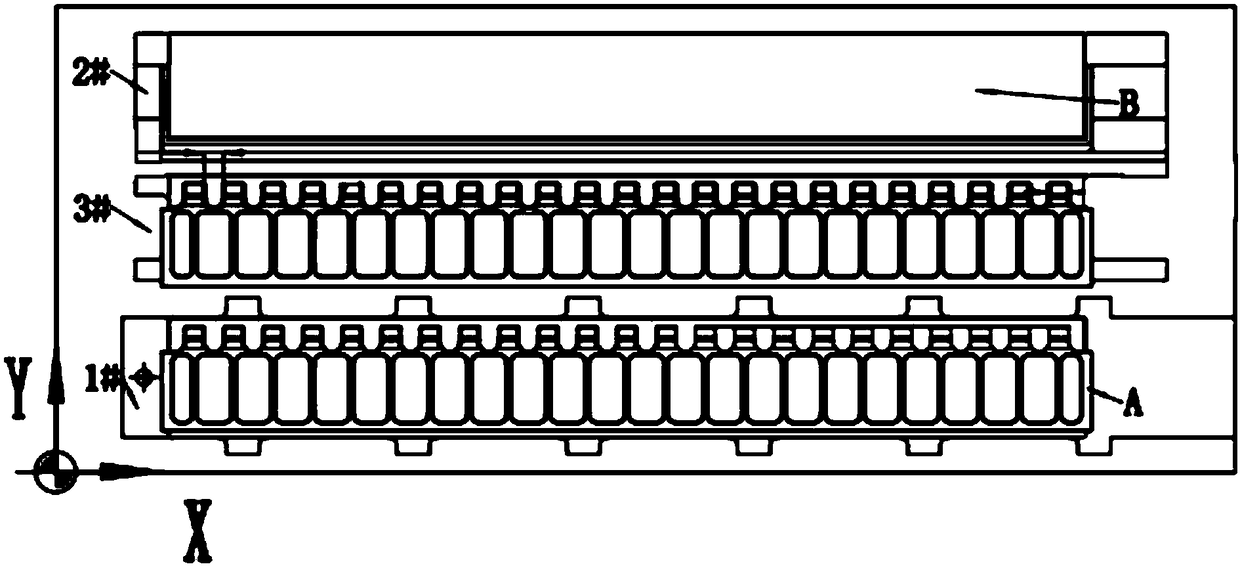

[0033] Such as figure 2 As shown, processing ZD4.0446.A.321.001 auxiliary intake valve. First correct the parts, the correction side is bent within 0.3mm, turn to CNC machining, fix the tooling, and straighten the tooling. according to figure 2 Establish the coordinate system, the tool setting point is on the upper surface of the tooling, install the parts on the 1# working step corresponding to the positioning groove I4-1, plug the 2# and 3# adsorption holes 3 to prevent air leakage, absorb the parts, and the vacuum pump gauge Start processing when the suction reaches 0.8MPa. Install the Φ80R0 disc cutter and start processing the A surface of the component, remove the 1.mm allowance, and ensure that the distance between the A surface and the reference hole is 2±0.15. Remove parts, deburr. Rotate the part around the X axis by 180°, install it on the 2# working step corresponding to the positioning groove II4-2, plug the remaining vacuum adsorption hole 3, mill the B surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com