Double-sided grinding machine

A double-sided grinding and grinding disc technology, which is applied in the direction of grinding machine tools, grinding devices, and grinding machine parts, can solve problems such as the inability of the ball joint to transmit power, affecting the parallelism of the machining accuracy, and the complex structure of the double-sided grinding machine. Achieve simple structure, reduce mobile energy consumption, and operate in compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

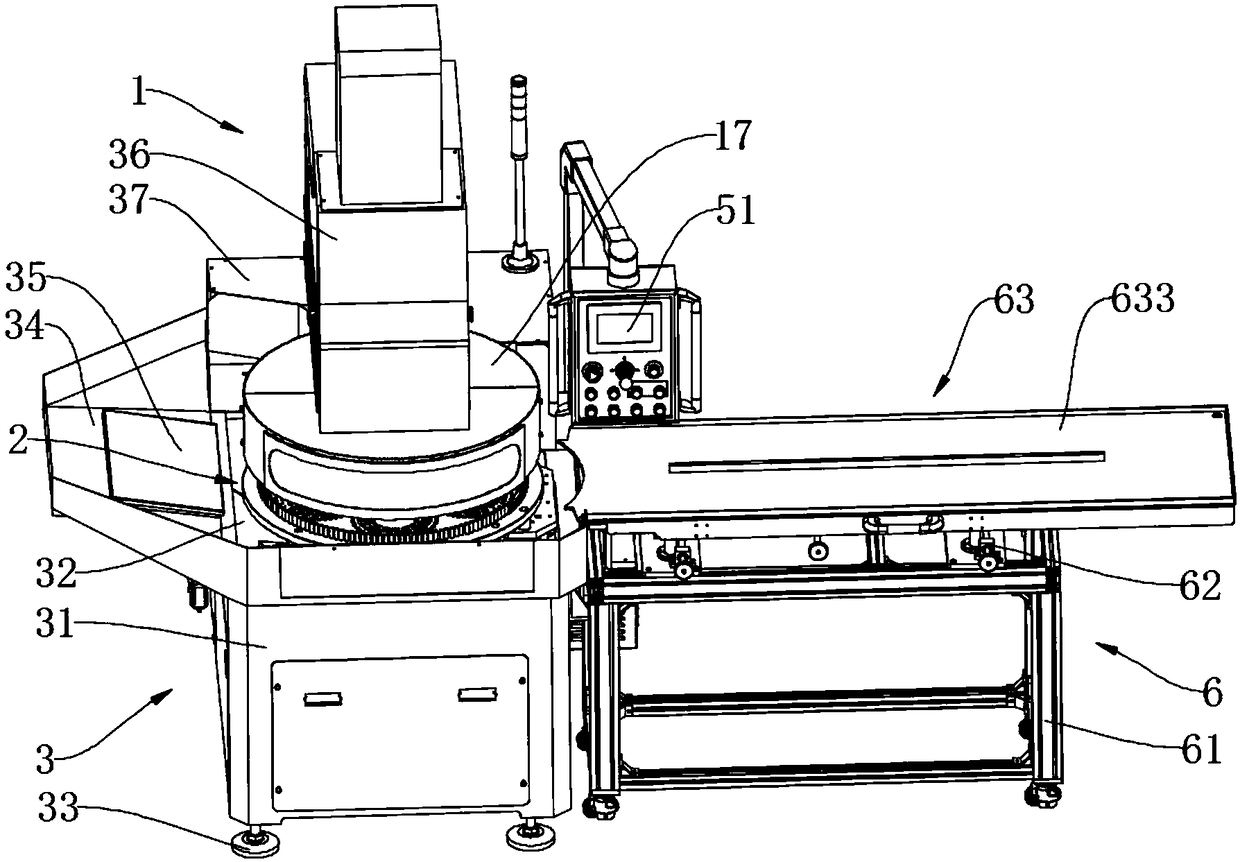

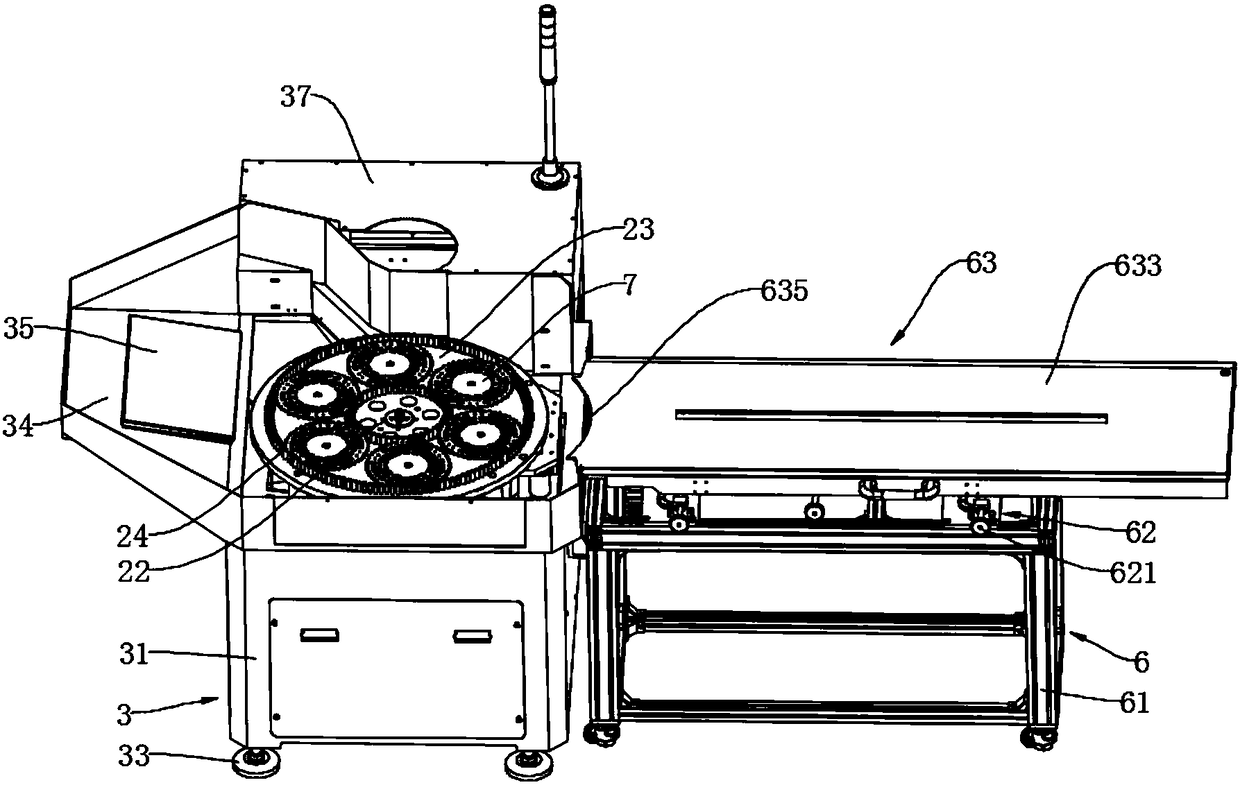

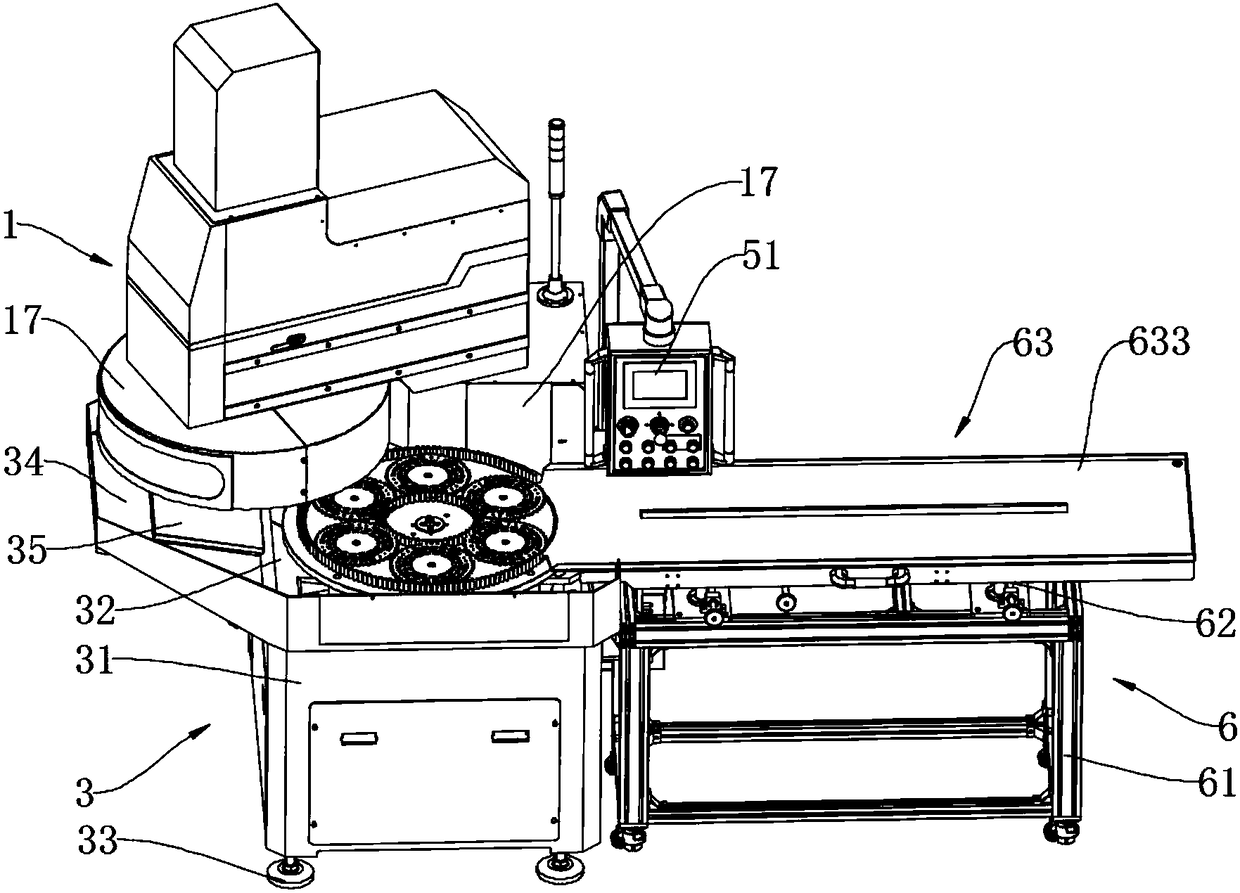

[0049] like figure 1 , image 3 and Figure 5 As shown, a double-sided grinding machine includes an upper grinding mechanism 1, a lower grinding mechanism 2, a frame mechanism 3, a rocker mechanism 4, an electric control mechanism, a loading and unloading table mechanism 6 and a clamp 7.

[0050] Frame mechanism 3 comprises lower frame 31 and supporting foot 33; Lower frame 31 is located on supporting foot 33, and supporting foot 33 supports lower frame 31, forms workbench 32 on the lower frame 31; Side is provided with water frame 34, to pick up the grinding liquid that drips; There is maintenance window on the water frame 34, is covered with dodge door 35 on the maintenance window, when this kind of double-sided grinder works normally, dodge door 35 covers Closed on the inspection window, when the upper grinding mechanism 1 needs to be overhauled and mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com