A mechanical pipe transport manipulator and its transformation method

A manipulator and mechanical technology, applied in the field of manipulators, can solve problems such as frequent replacement of tooth plates, bite marks of tooth plates, etc., achieve the effect of reducing production costs and maintenance costs, and expanding the range of use environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

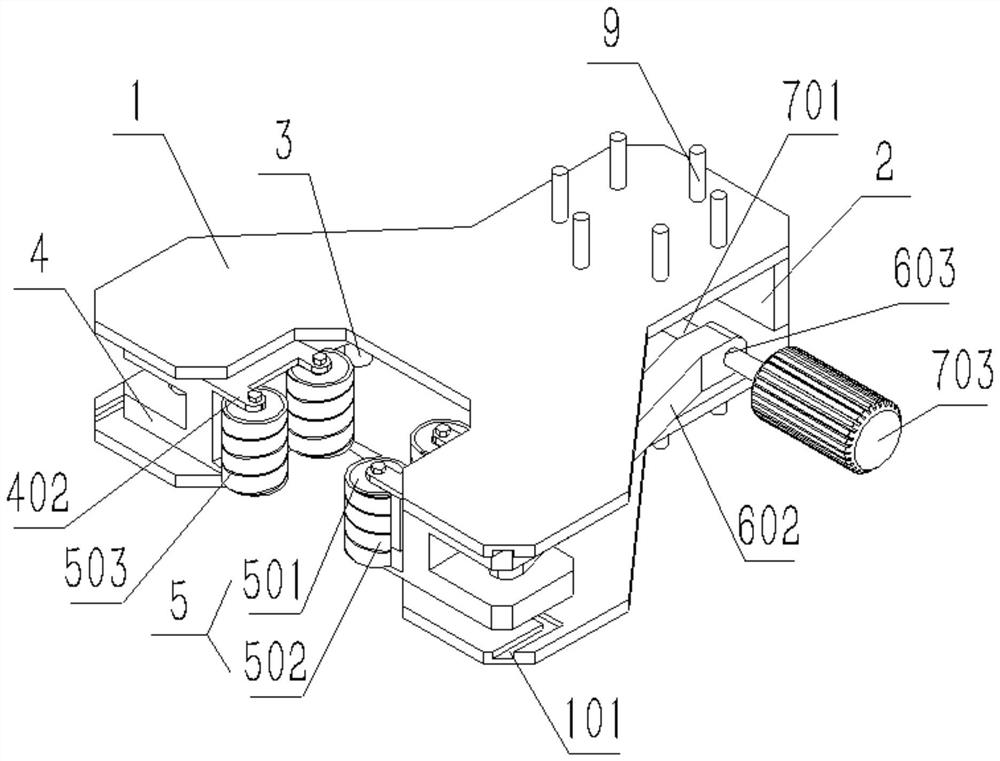

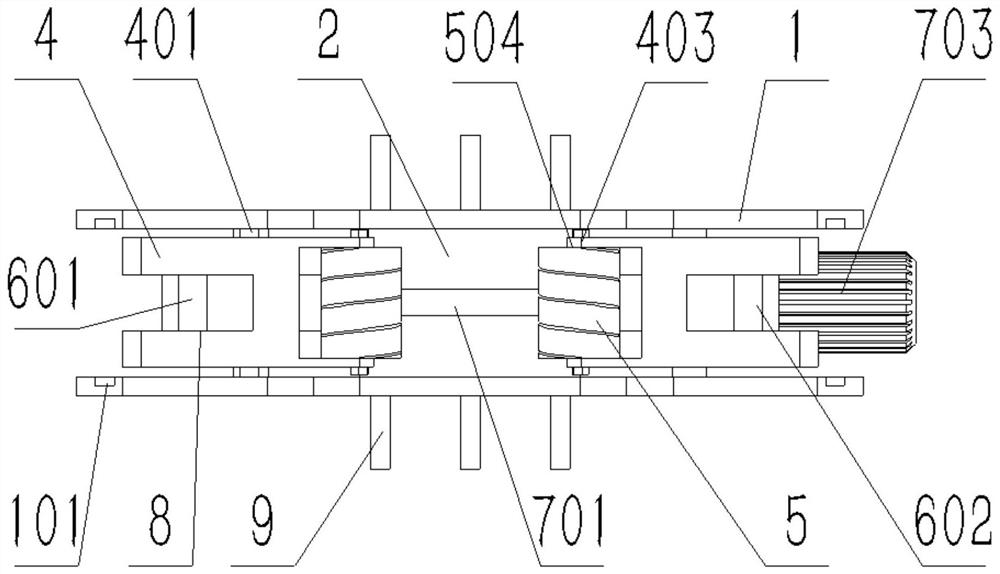

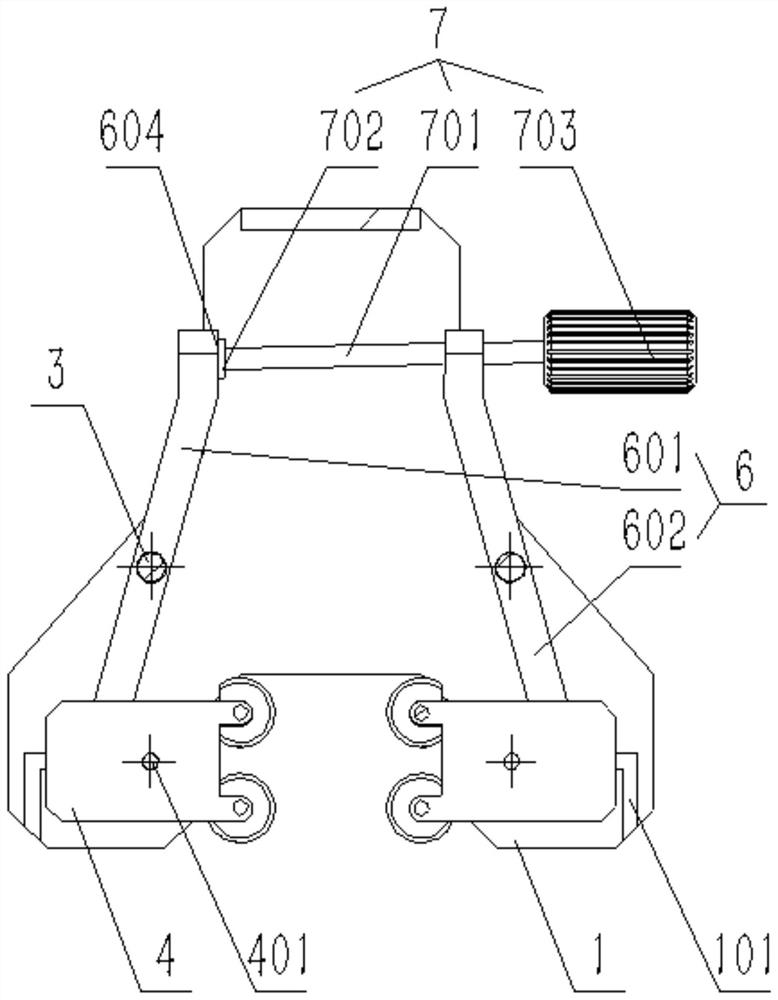

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Please see attached figure 1 to attach image 3 As shown, a mechanical pipe transportation manipulator includes a support plate 1, a ridge plate 2, a hinge column 3, a slider 4, a roller 5, a connecting rod group 6 and a screw mechanism 7; a pair of the support plates 1 are spaced arrangement; the spine plate 2 is arranged between a pair of support plates, and the spine plate 2 is connected to the support plate 1 by welding; the hinge column 3 is a cylindrical structure; A pair of hinge columns 3 is arranged between a pair of support plates 1, and the two are connected by welding; the slider 4 is a rectangular body structure, and a pair of sliders 4 are set Between the support plates 1; a pair of "L"-shaped chute 101 is opened on the inner side of the front part of the support plate 1, and the cross section of the chute 101 is rectangular; the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com