Preparation method of nano-crystal

A nanocrystal and synthetic method technology, which is applied in the preparation of organic compounds, carbon-based compounds, chemical instruments and methods, etc., can solve the problems of poor precision, unenvironmental protection, and complex nanocrystal process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for synthesizing nanocrystals, comprising:

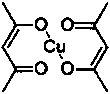

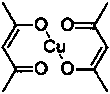

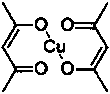

[0017]

[0018] Step 2: Then add 0.1mL ethylene glycol to the above reaction vial with a pipette, raise the temperature to 160°C under 1atmCO atmosphere, and keep it for 3h;

[0019] Step 3: After cooling, add 15mL ethanol to the bottle and let it stand for 1h;

[0020] Step 4: pour off the upper layer solution, wash 2-3 times according to the above method, then transfer the product to a centrifuge tube and centrifuge with a mixed solvent of cyclohexane and ethanol to obtain an intermediate product;

[0021] Step 5: Add 10 mg of platinum acetylacetonate, 0.11 mg of sodium hexachloroplatinate, 0.1 mg of the intermediate product obtained in step 4, 2 mg of molybdenum hexacarbonyl and 6 mg of nickel acetylacetonate into a 10 mL pressure bottle;

[0022] Step 6: Then add 3 mL of oleylamine to the bottle with a pipette;

[0023] Step 7: the flask is transferred to a high temperature oil bath;

[0024] Step 8: in 5at...

Embodiment 2

[0028] A method for synthesizing nanocrystals, comprising:

[0029]

[0030] Step 2: Then add 0.1mL ethylene glycol to the above reaction vial with a pipette, raise the temperature to 160°C under 1atmCO atmosphere, and keep it for 3h;

[0031] Step 3: After cooling, add 15mL ethanol to the bottle and let it stand for 1h;

[0032] Step 4: pour off the upper layer solution, wash 2-3 times according to the above method, then transfer the product to a centrifuge tube and centrifuge with a mixed solvent of cyclohexane and ethanol to obtain an intermediate product;

[0033] Step 5: Add 10 mg of platinum acetylacetonate, 0.11 mg of sodium hexachloroplatinate, 0.1 mg of the intermediate product obtained in step 4, 2 mg of molybdenum hexacarbonyl and 6 mg of nickel acetylacetonate into a 10 mL pressure bottle;

[0034] Step 6: Then add 3 mL of oleylamine to the bottle with a pipette;

[0035] Step 7: the flask is transferred to a high temperature oil bath;

[0036] Step 8: in 5at...

Embodiment 3

[0040] A method for synthesizing nanocrystals, comprising:

[0041]

[0042] Step 2: Then add 0.1mL ethylene glycol to the above reaction vial with a pipette, raise the temperature to 160°C under 1atmCO atmosphere, and keep it for 3h;

[0043] Step 3: After cooling, add 15mL ethanol to the bottle and let it stand for 1h;

[0044] Step 4: pour off the upper layer solution, wash 2-3 times according to the above method, then transfer the product to a centrifuge tube and centrifuge with a mixed solvent of cyclohexane and ethanol to obtain an intermediate product;

[0045] Step 5: Add 10 mg of platinum acetylacetonate, 0.11 mg of sodium hexachloroplatinate, 0.1 mg of the intermediate product obtained in step 4, 2 mg of molybdenum hexacarbonyl and 6 mg of nickel acetylacetonate into a 10 mL pressure bottle;

[0046] Step 6: Then add 3 mL of oleylamine to the bottle with a pipette;

[0047] Step 7: the flask is transferred to a high temperature oil bath;

[0048] Step 8: in 5at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com