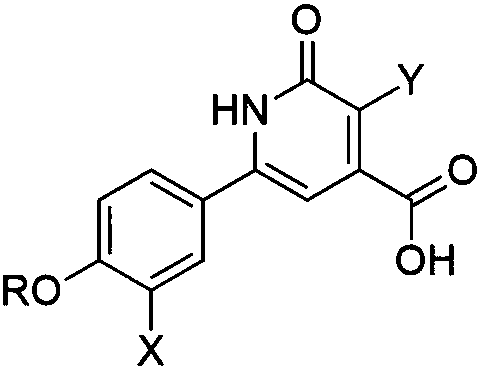

2-oxo-1, 2-dihydropyridine-4-formic compound

A technology of compound and formic acid, which is applied in the field of 2-oxo-1,2-dihydropyridine-4-carboxylic acid compounds, can solve the rare problems of synthesis and application research, and achieve a simple and feasible preparation method with good yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

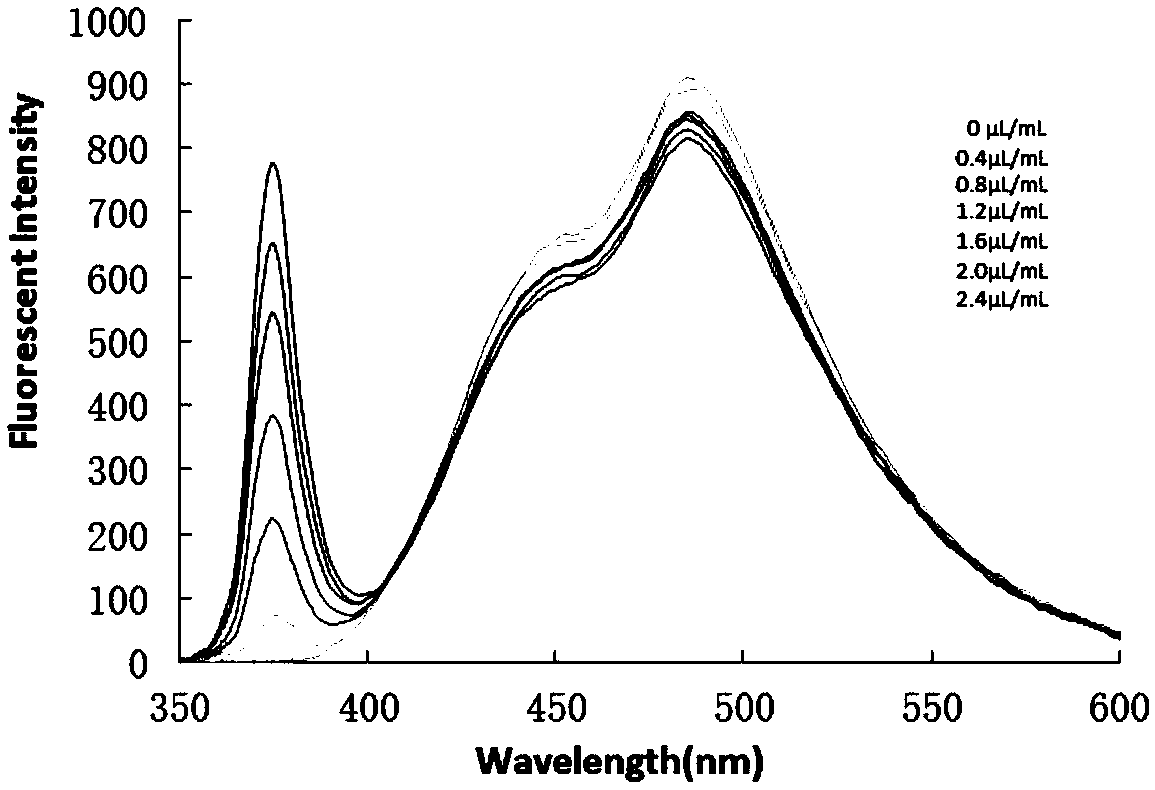

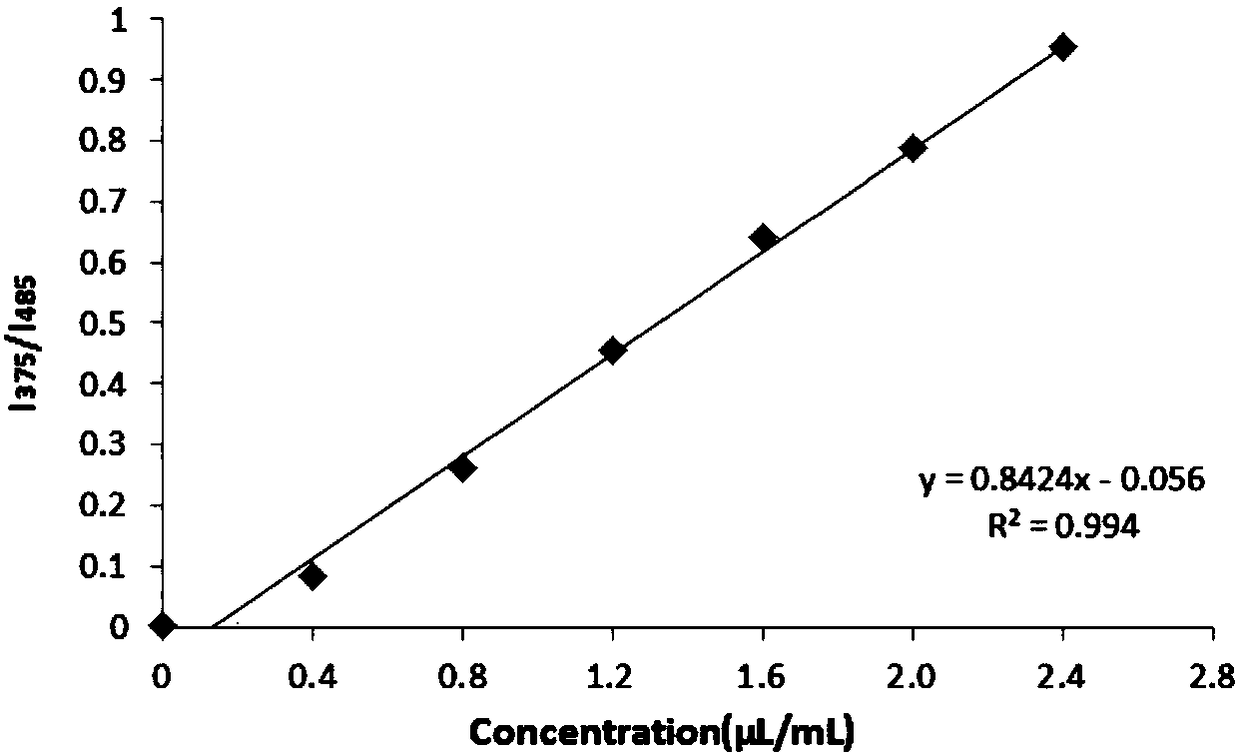

Image

Examples

Embodiment 1

[0037] (1) Cyclization reaction:

[0038] (Z)-4-(3-cyano-4-isobutoxyphenyl)-2-hydroxy-4-oxobut-2-enoic acid methyl ester (1.52g, 5mmol), cyanoacetamide (0.42g, 5mmol), anhydrous potassium carbonate (1.38g, 10mmol), were added to 25mL DMF, heated to 57°C for 10h. The reaction solution was poured into 50 mL of water and extracted with ethyl acetate (30 mL×2). The organic phases were combined and dried over anhydrous magnesium sulfate. The solvent was removed by rotary evaporation. The crude product was recrystallized from ethanol to obtain methyl 3-cyano-6-(3-cyano-4-isobutoxyphenyl)-2-oxo-1,2-dihydropyridine-4-carboxylate, yield 73%.

[0039] (2) Hydrolysis reaction:

[0040] Methyl 3-cyano-6-(3-cyano-4-isobutoxyphenyl)-2-pyridone-4-carboxylate (1.05 g, 3 mmol), 20 mL of 1M NaOH solution, 5 mL of ethanol. Reaction at room temperature for 1.5h. 1M HCl solution was added dropwise to the system to adjust the pH of the system to 5, and a solid precipitated out. Suction filtra...

Embodiment 2

[0042] Example 2: Preparation of 3-carbamoyl-6-(3-cyano-4-isobutoxyphenyl)-2-oxo-1,2-dihydropyridine-4-carboxylic acid (compound 2)

[0043] 3-cyano-6-(3-cyano-4-isobutoxyphenyl)-2-oxo-1,2-dihydropyridine-4-carboxylic acid (compound 1) prepared in Example 1 As a raw material, 3-carbamoyl-6-(3-cyano-4-isobutoxyphenyl)-2-oxo-1,2-dihydropyridine-4-carboxylic acid (compound 2).

[0044] Hydrolysis reaction:

[0045] 3-cyano-6-(3-cyano-4-isobutoxyphenyl)-2-pyridone-4-carboxylic acid (compound 1) (0.34g, 1mmol), 20mL 1M HCl solution, 5mL methanol . The temperature was raised to 55°C for 15h. Part of the solvent was removed by rotary evaporation, and solid was precipitated by cooling. Suction filtration, the filter cake was washed with water, and the crude product was recrystallized from ethanol to obtain 3-carbamoyl-6-(3-cyano-4-isobutoxyphenyl)-2-pyridone-4-carboxylic acid (compound 2) . The total yield was 49% (based on raw material (Z)-4-(3-cyano-4-isobutoxyphenyl)-2-hydro...

Embodiment 3

[0046] Example 3: Preparation of 3-carbamoyl-6-(3-cyano-4-isopropoxyphenyl)-2-oxo-1,2-dihydropyridine-4-carboxylic acid (compound 3)

[0047] Using (Z)-4-(3-cyano-4-isopropoxyphenyl)-2-hydroxyl-4-oxobut-2-enoic acid methyl ester as raw material, through the same method as in Example 2 Obtain 3-carbamoyl-6-(3-cyano-4-isopropoxyphenyl)-2-oxo-1,2-dihydropyridine-4-carboxylic acid (compound 3), the total yield is 45% (based on raw material (Z)-4-(3-cyano-4-isopropoxyphenyl)-2-hydroxyl-4-oxobut-2-enoic acid methyl ester), its structural formula, 1 H-NMR and MS data are listed in Table-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com