Anti-mildew wash bottle additive, and preparation method and application method thereof

An additive and bottle washing technology, which is applied in the preparation of detergent mixture composition, detergent composition, detergent compounding agent, etc., can solve problems such as difficult operation, increased energy consumption such as water and electricity, and difficult washing process, etc. To achieve the effect of easy water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example 1

[0028] The mildew-removing and bottle-washing additive provided in this embodiment is composed of the following components by weight:

[0029] Sodium bicarbonate 60

[0030] Sodium percarbonate 30

[0031] Chelating agent 10

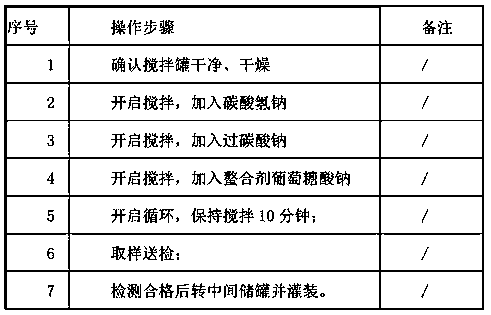

[0032] Production Process

[0033]

[0034] Instructions:

[0035] Add the mildew-removing and bottle-washing additive prepared in this embodiment to a sodium hydroxide solution with an effective alkali content of 2% at a rate of 0.5%. After circulating the mildew beer bottle at 70°C-85°C for 20 minutes, Wash with water again.

[0036] The use effect of the mildew-removing and bottle-washing additive prepared in this embodiment:

[0037] The label of the cleaned glass bottle body is peeled off as it is without any glue marks, the bottle body is bright and transparent, and there is no water droplets on the inside and outside of the bottle, and the mold stain cleaning rate reaches 99.9%.

[0038] It is proved that the combination of the additive for d...

Example Embodiment

[0039] Example 2

[0040] The mildew-removing and bottle-washing additive provided in this embodiment is composed of the following components by weight:

[0041] Sodium bicarbonate 55

[0042] Sodium percarbonate 30

[0043] Chelating agent 15

[0044] Production process: same as Example 1, wherein the chelating agent is sodium tripolyphosphate.

[0045] Method of use: same as Example 1

[0046] The use effect of the mildew-removing and bottle-washing additive prepared in this embodiment:

[0047] The label of the cleaned glass bottle body is peeled off as it is without glue marks, the bottle body is bright and transparent, and there is no water droplets on the inside and outside of the bottle, and the mold stain cleaning rate reaches 99.6%.

[0048] It is proved that the combination of the additive for de-mildew washing bottles and the alkaline cleaning agent of the present invention can effectively remove mildew spots, insect eggs and bottle labels in glass bottles. In addition, the clea...

Example Embodiment

[0049] Example 3

[0050] The beer industry beer bottle demolition and bottle washing additive provided in this embodiment is composed of the following components by weight:

[0051] Sodium bicarbonate 70

[0052] Sodium percarbonate 25

[0053] Chelating agent 5

[0054] Production process: same as Example 1, wherein the chelating agent is EDTA-4Na.

[0055] Method of use: same as Example 1

[0056] The use effect of the mildew-removing and bottle-washing additive prepared in this embodiment:

[0057] The label of the cleaned glass bottle body is peeled off as it is without glue marks, the bottle body is bright and transparent, there is no water droplets on the inside and outside of the bottle, and the mold stain cleaning rate reaches 99.8%.

[0058] It is proved that the combination of the additive for de-mildew washing bottles and the alkaline cleaning agent of the present invention can effectively remove mildew spots, insect eggs and bottle labels in glass bottles. In addition, the cle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap