Cooling device for machining and quenching of stepped drill

A cooling device and step drill technology, applied in the direction of quenching device, quenching agent, manufacturing tools, etc., can solve the problems of time-consuming and laborious manual operation, failure to work normally, splashing, etc., to reduce additional consumption, good purging effect, and cooling good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

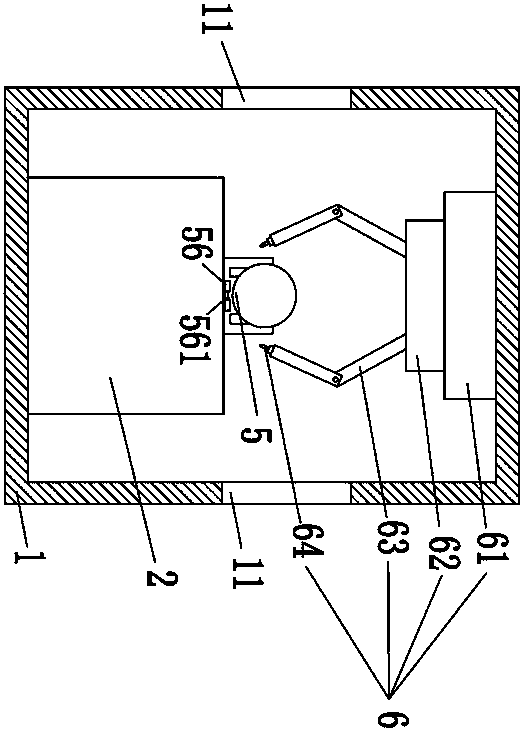

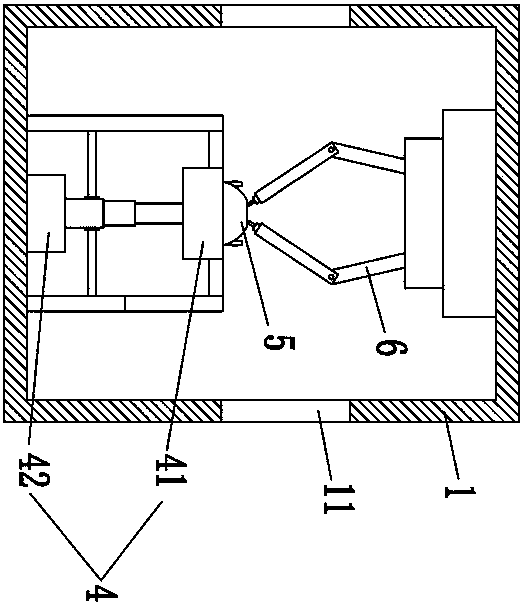

[0023] Such as Figure 1-6 As shown, a cooling device for processing step drill quenching, including a cooling device housing 1, a cooling platform 2 and a PLC controller 3, the cooling platform 2 is arranged in the cooling device housing 1, and is arranged in the cooling device housing 1 bottom, the cooling table 2 is provided with an oil storage tank 21, the oil storage tank 21 is filled with cooling oil, the PLC controller 3 is arranged on the cooling device housing 1, and the cooling device housing 1 There are electric telescopic doors 11 on both sides, and the electric telescopic doors 11 are arranged in the middle of both sides of the cooling device shell 1. The electric telescopic doors 11 on the left side are the feeding end of the cooling device shell 1, and The electric telescopic door 11 is the discharge end of the cooling device housing 1, and the cooling device housing 1 is also provided with a lifting mechanism 4, a telescopic mechanism 5 and an oil removal mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com