Ionic exchange membrane electrolytic cell device and system and method of electrolytic etching waste liquid

A technology of ionic membrane electrolyzer and etching waste liquid, which is applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc. It can solve the problems of electrolyzer work influence, easy fatigue, accidents, etc., and achieve the reduction of work risk factor, Less fatigue and longer service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In the following specific description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from this description, therefore, the protection scope of the present invention is not limited by the specific implementation disclosed below. Example limitations.

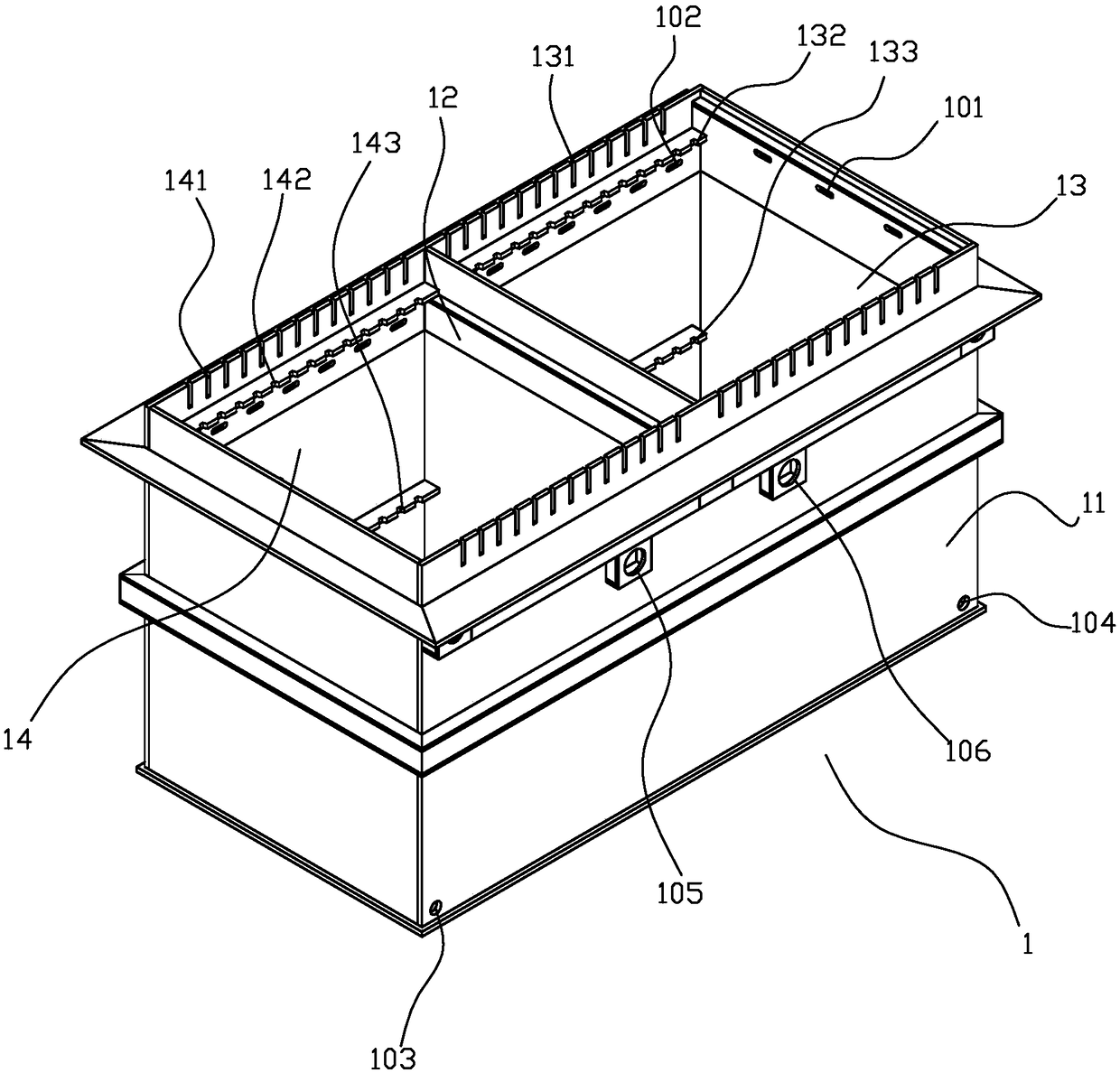

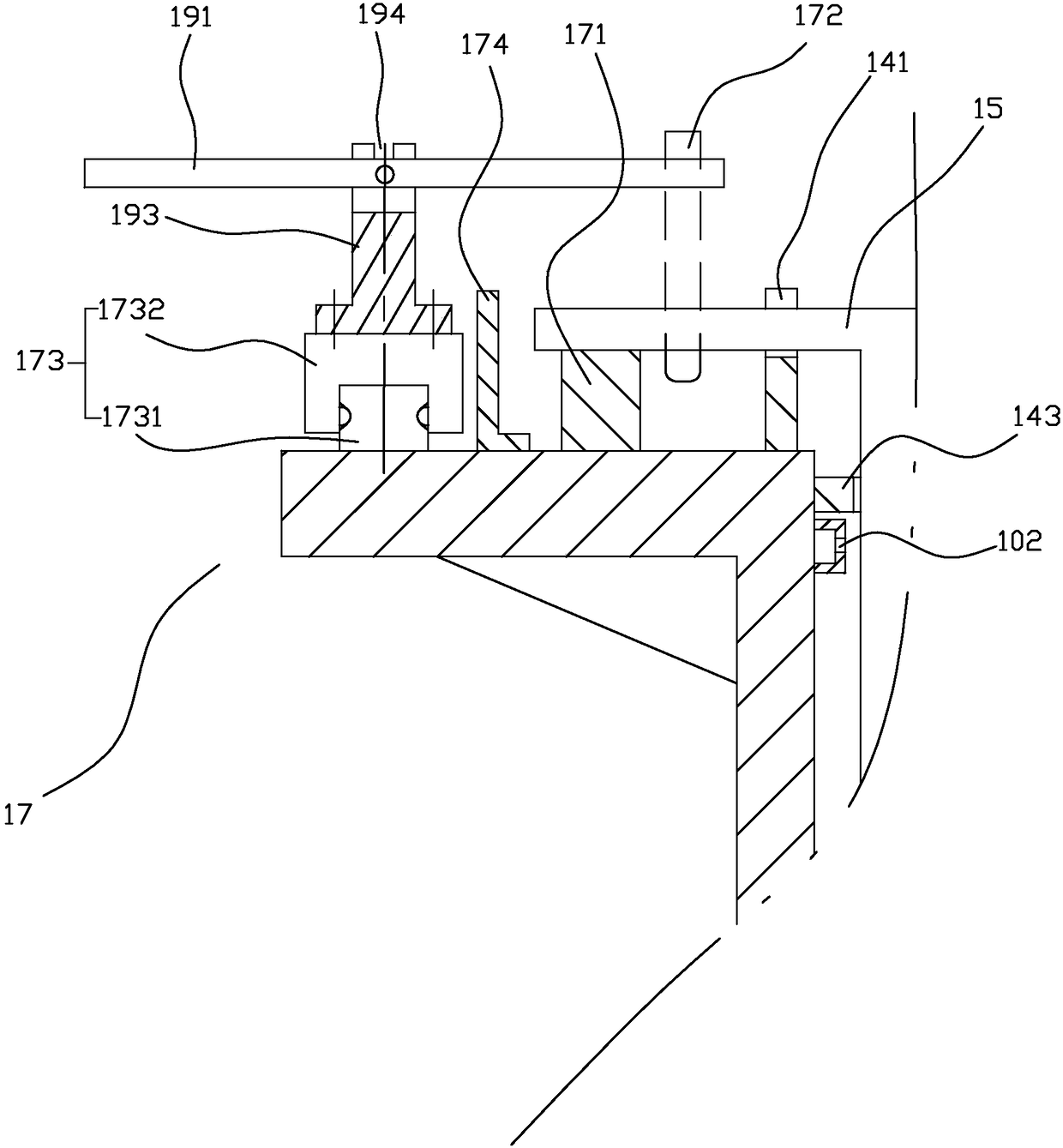

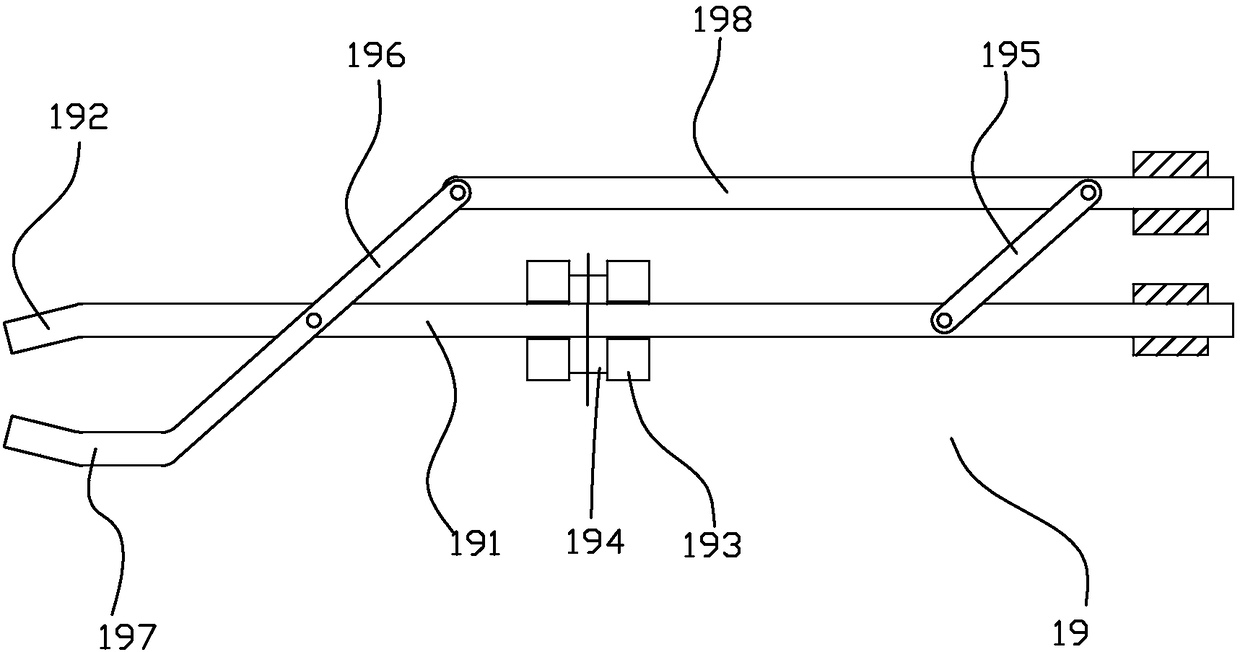

[0058] Such as figure 1 As shown, a kind of ionic membrane electrolyzer device 1 of the present invention, comprises the tank body 11 that opening faces upwards, is provided with the anticorrosion plastic mold frame 12 of vertical direction in the cavity of tank body 11, and plastic mold frame 12 is provided with ion Membrane, the ionic membrane separates the cavity into a cathode area 13 and an anode area 14, and the cathode area 13 is provided with several vertical cathode plates; the anode area 14 is provided with several vertical anode plates, and the cathode area 13 both sides The upper edge of the catho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com