A stationary detonation engine based on variable wedge angle

A technology of detonation engine and wedge, which is applied in the direction of machine/engine, mechanical equipment, gas turbine device, etc., can solve the problems of uncontrollable technology and increase combustion loss, so as to save the ignition device, reduce the weight of the structure and reduce the loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

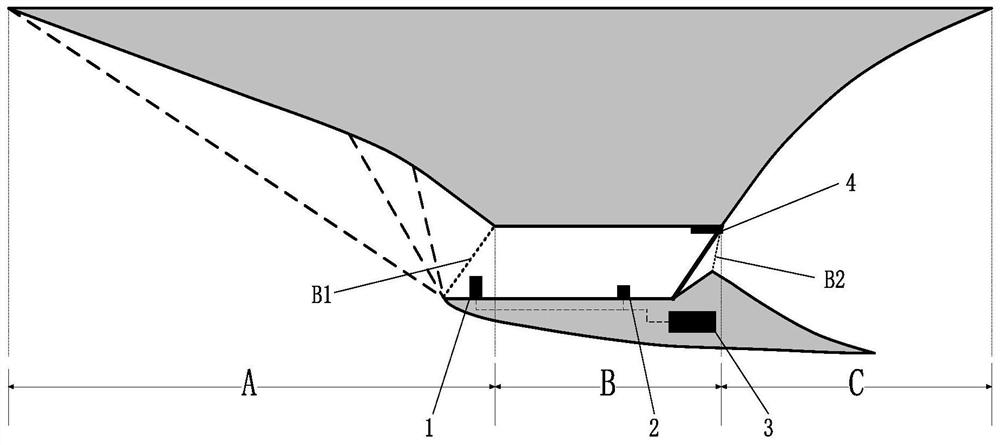

[0031] Such as figure 1 Shown is a stationary detonation engine based on a variable wedge angle, including: intake port A, detonation combustion chamber B, tail nozzle C, where the intake port A is designed as an inclined or curved channel structure, Thereby, the incoming air entering the air inlet A can generate oblique shock waves, and different structures can be selected according to different design indicators, such as waverider structures such as two-shock wave and three-shock wave structures. The detonation combustion chamber B has a combustion chamber inlet B1 and a combustion chamber outlet B2, the combustion chamber inlet B1 communicates with the inlet port A outlet, and the combustion chamber outlet B2 communicates with the tail nozzle C inlet.

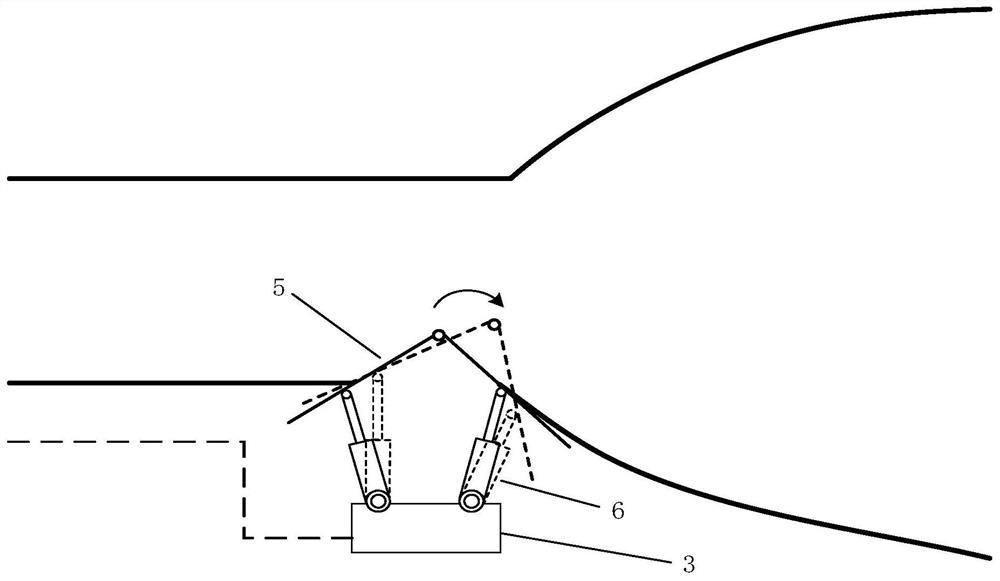

[0032] In this embodiment, its structure further includes a fuel injection and atomization device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com