Dynamic water power balance adjusting method for primary side water supply net of heat exchange station system

A technology of dynamic balance and heat exchange station, applied in the direction of heating system, heating method, high-efficiency regulation technology, etc., can solve problems such as resistance imbalance, hydraulic imbalance, throttling element damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

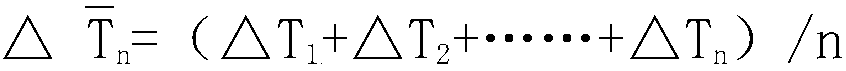

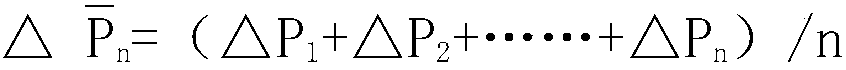

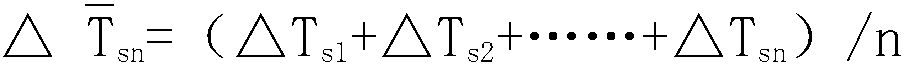

[0049] The invention provides a method for adjusting the hydraulic dynamic balance of the water supply network on the primary side of the heat exchange station system, comprising the following steps:

[0050] 1) Data collection

[0051] For the collection of water supply temperature, return water temperature, water supply pressure and return water pressure parameters of the pipe network, the temperature parameters are collected by the temperature sensor installed on the pipeline, and the pressure parameters are collected by the pressure sensor installed on the pipeline, and then through the data The acquisition box converts the data collected by the temperature sensor and the pressure sensor into digital signals and transmits them to the computer;

[0052] Data collection:

[0053] a. Temperature detection

[0054] Detect the temperature T of the main water supply pipe through the water temperature sensor in the main water supply pipe g ;

[0055] The temperature T of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com