Rice grain forming and drying equipment of daur aimen egg drop soup production line and using method thereof

A drying equipment and a technology for forming rice grains, applied in the field of rice grain forming and drying equipment for the production line of Artemisia sprouts and egg flower soup, can solve the problems of affecting the moisture content and fullness, high heating temperature, low heating temperature, etc., to ensure the moisture content. and fullness, ease of use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

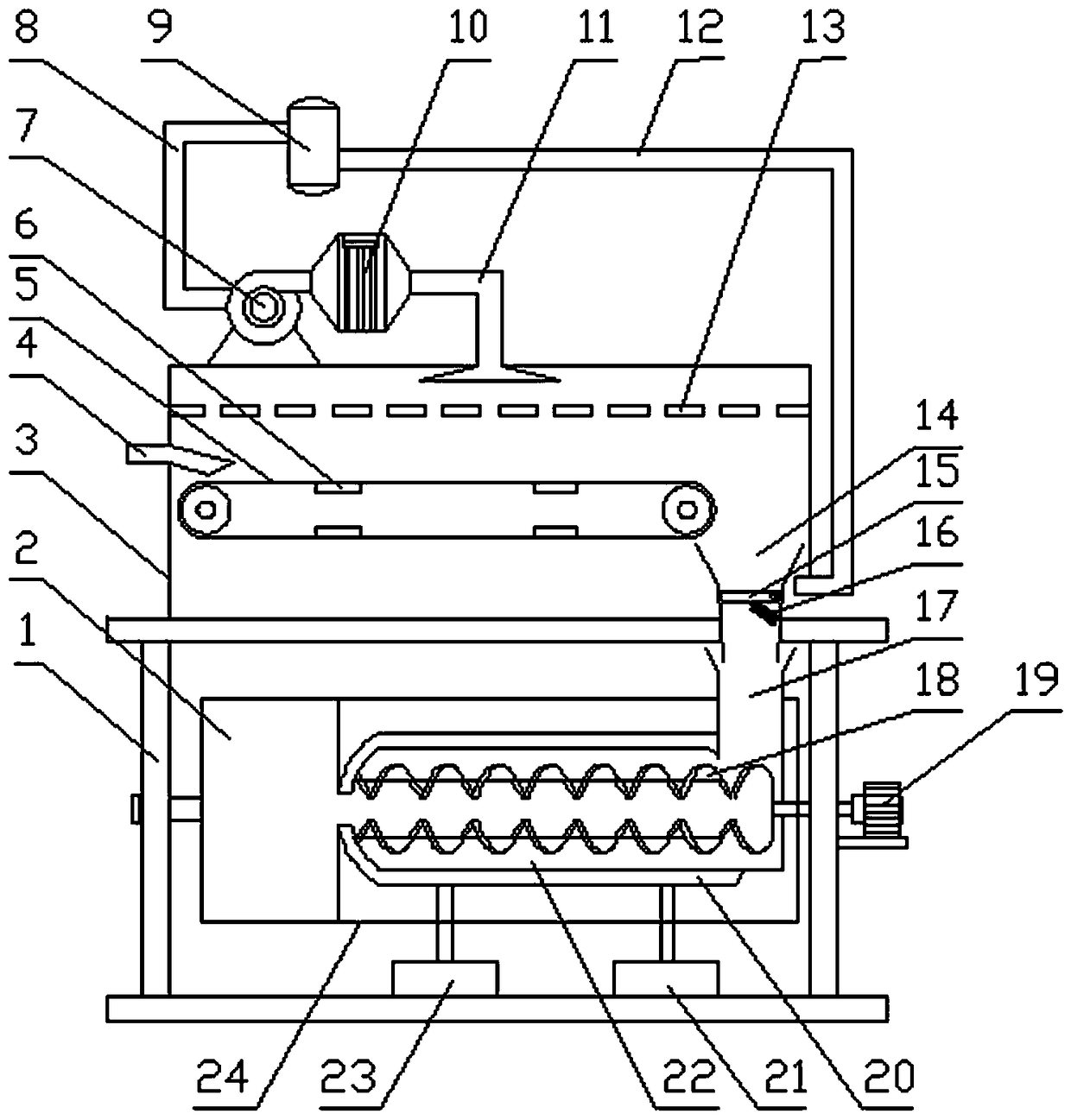

[0029] refer to figure 1 , the present invention specifically adopts the following embodiments: comprising a device frame 1, a first drying box 3 and a second drying box 24, the top of the device frame 1 is provided with a first drying box 3, and the middle horizontal frame of the device frame 1 has a second Drying box 24, the top of the first drying box 3 is provided with an electric heating box 10 and a blower fan 7, the output end of the electric heating box 10 communicates with the inside of the first drying box 3 through the heat inlet pipe 11, and the input end of the electric heating box 10 is connected to the output of the blower fan 7 The input end of the fan 7 is connected to the output end of the drying box 9 through the circulating air pipe 8, and the input pipe of the drying box 9 communicates with the inside of the first drying box 3 through the heat outlet pipe 12, and the upper part of the first drying box 3 Horizontal frame hot air distribution plate 13, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com